Method for manufacturing enhanced gallium nitride power device

A technology of power devices and gallium nitride, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as large on-resistance, poor device characteristics, and negative threshold value, so as to reduce the difficulty of the process, The effect of avoiding barrier layer interface damage and improving process efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

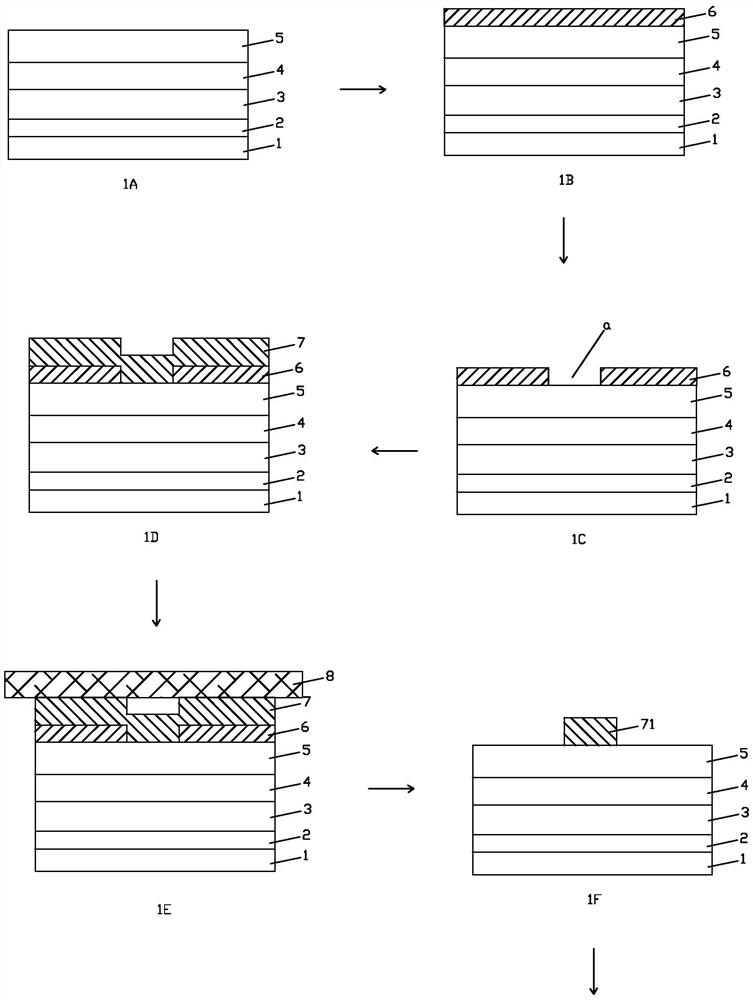

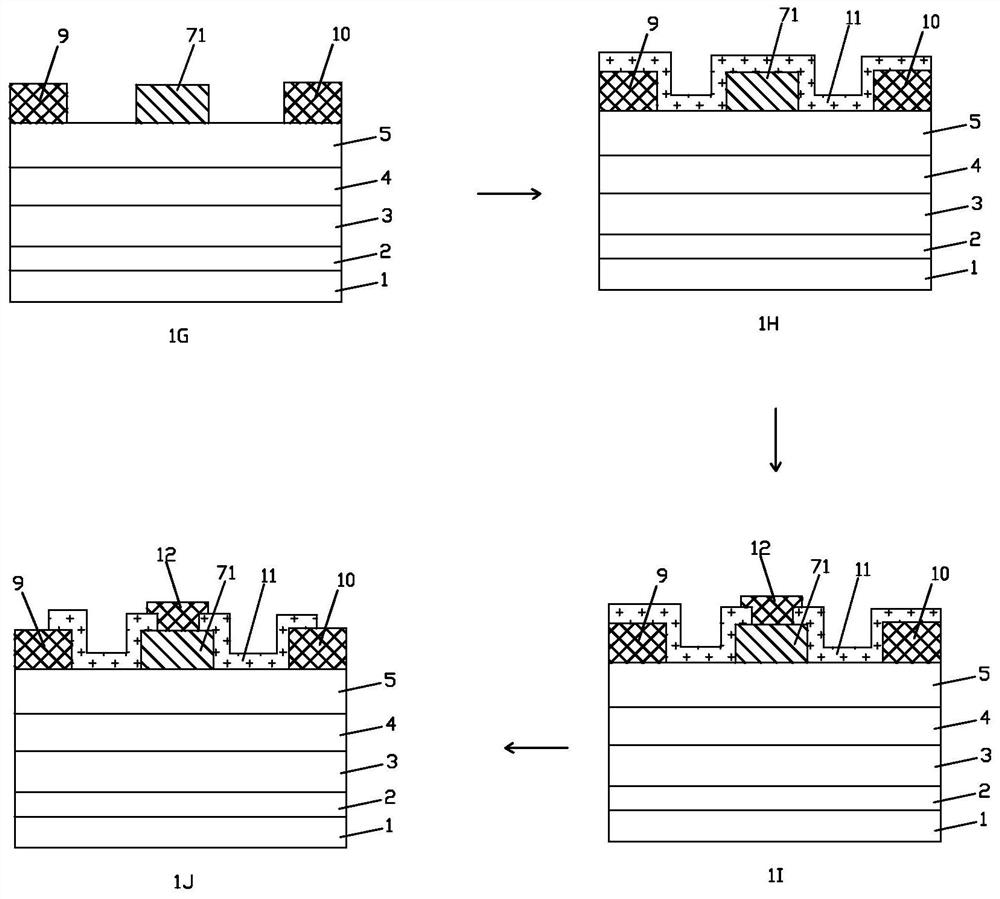

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The accompanying drawings of the present invention are only schematic for easier understanding of the present invention, and the specific proportions thereof can be adjusted according to design requirements. Those skilled in the art should understand that the upper and lower relationships of relative components in the figures described herein refer to the relative positions of the components, so all of them can be turned over to present the same components, which should all fall within the scope of the present specification. In addition, the numbers of components and structures shown in the figure are only examples, and are not intended to limit the numbers, and can be adjusted according to actual design requirements.

[0032] refer to figure 1 1A, a semiconductor substrate is provided, and the semiconductor substrate includes an Si substrate 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com