Multi-mode automatic sealing cap control expansion machine

A technology of expansion machine and cap sealing, which is applied in the field of plastic processing, can solve problems such as the difference in preheating temperature of cap sealing, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

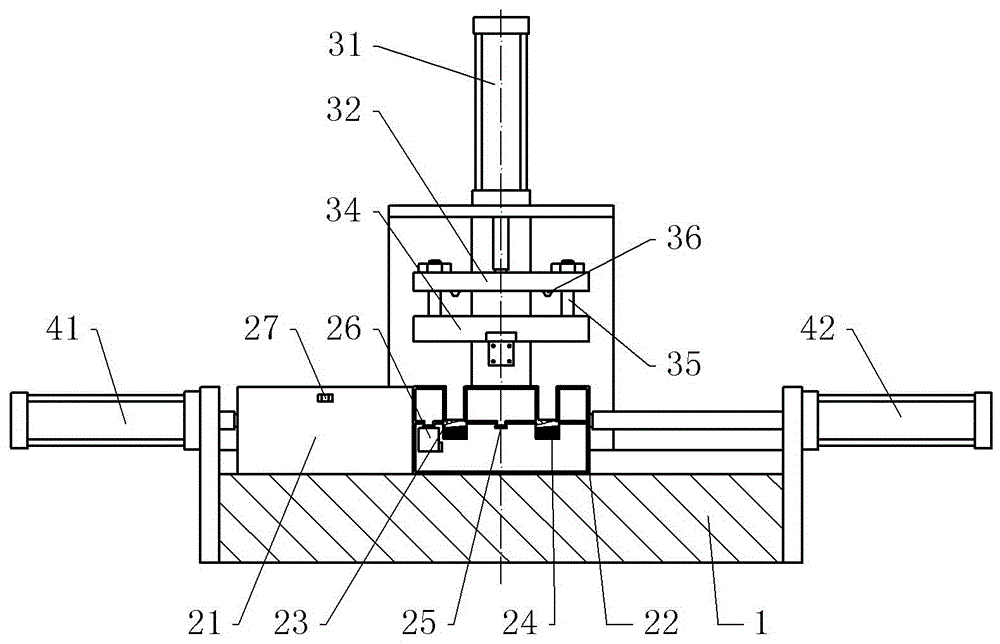

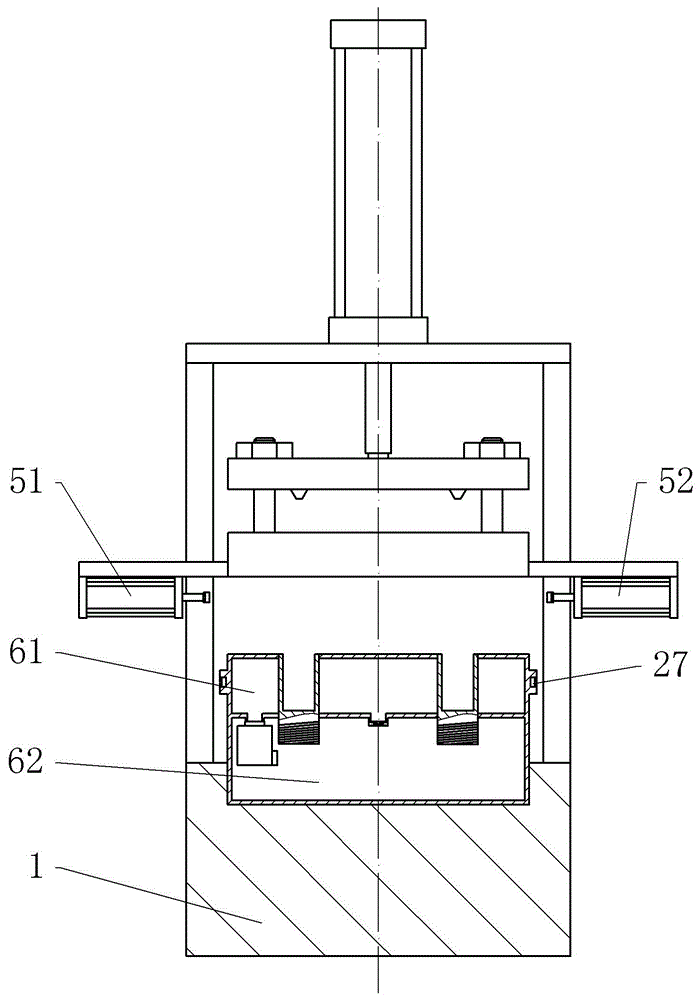

[0023] The reference signs in the drawings of the description include: frame 1, mold body 1 21, mold body 2 22, mold cover 23, electromagnetic heating coil 24, exhaust valve 25, compressor 26, positioning groove 27, driving cylinder 31 , pressing plate 32, guide plate 34, pull rod 35, gas nozzle 36, left push part 41, right push part 42, fixed cylinder one 51, fixed cylinder two 52, compression chamber 61, expansion chamber 62.

[0024] The embodiment is basically as figure 1 , figure 2 Shown:

[0025] The capping multi-mode automatic control expansion machine of the present embodiment includes a molding device, a guide device and a mold body arranged on the frame 1; the molding device includes a driving cylinder 31 and a pressing plate 32, and the driving cylinder 31 passes through the connecting rod and the pressing plate 32 The upper surface of the upper surface is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com