A rare earth slag glass-ceramic and its preparation method

A technology of glass-ceramic and slag, applied in the field of rare-earth slag glass-ceramic and its preparation, can solve problems such as environmental and human threats, and achieve the effects of wide component requirements, refined crystal grains and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

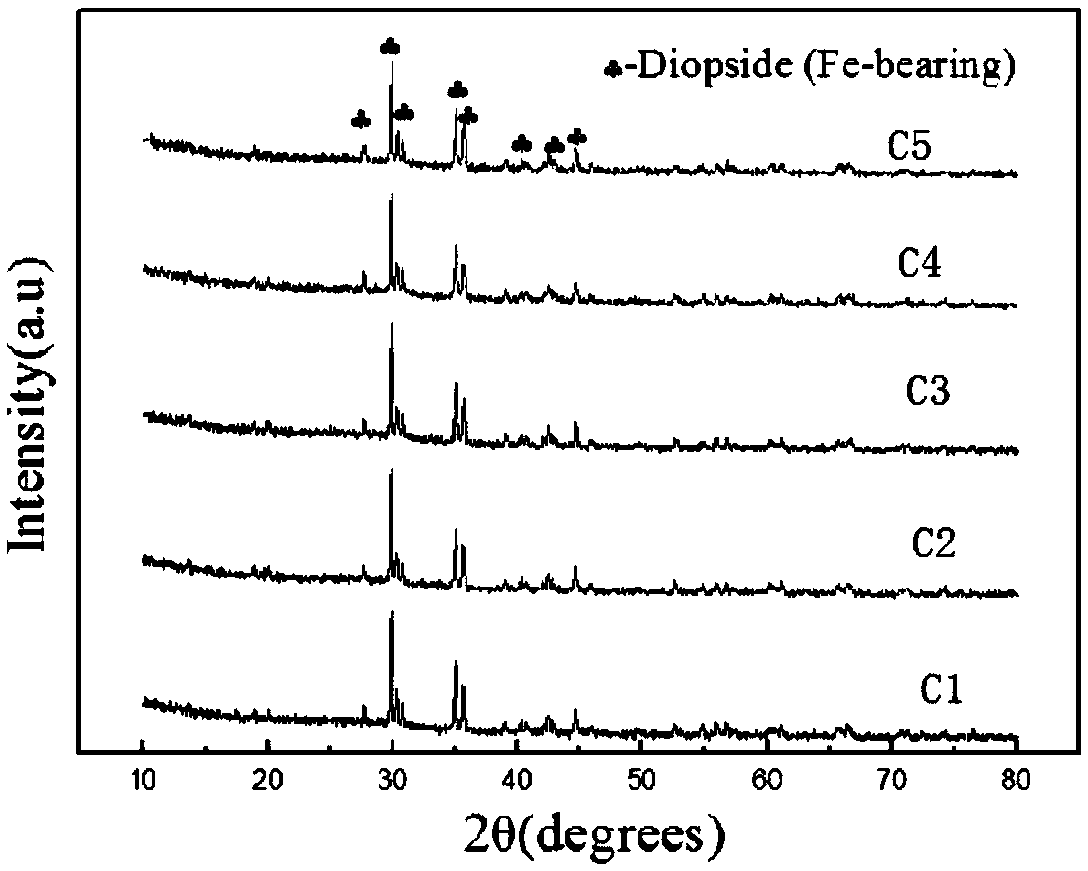

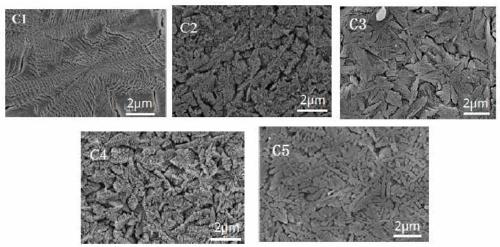

Image

Examples

Embodiment 1

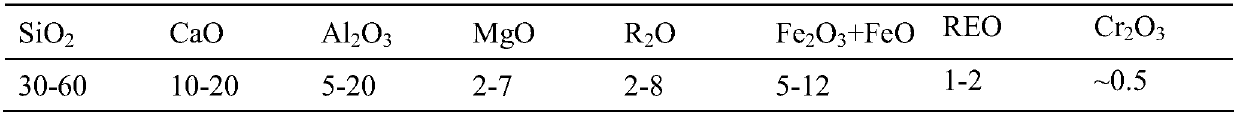

[0027] Embodiment 1: a kind of rare earth slag glass ceramics and its preparation method, its manufacture method is as follows:

[0028] (1) Preparation of rare earth-containing additives. Weigh 36 parts of Baiyun Obo secondary beneficiation tailings, 49 parts of Baotou steel blast furnace slag powder, and 15 parts of stainless steel slag powder according to weight percentage. Add it into a mixer and mix evenly to obtain the rare earth-containing additive. The "parts" mentioned in the present invention are all parts by weight.

[0029] (2) Weigh 6 parts of rare earth-containing additives, 30 parts of copper tailings, 18 parts of iron tailings, 25 parts of fly ash, 15 parts of quartz sand, 3 parts of borax, and 3 parts of sodium carbonate by weight percentage. Then add the weighed rare earth-containing additive, copper tailings, iron tailings, fly ash, quartz sand, borax, and sodium carbonate into a mixer and mix evenly to obtain a mixture.

[0030](3) Send the mixture into ...

Embodiment 2

[0035] Embodiment 2: a kind of rare earth slag glass ceramics and its preparation method, its manufacture method is as follows:

[0036] (1) Preparation of rare earth-containing additives. Weigh 40 parts of Baiyun Obo secondary beneficiation tailings, 40 parts of Baotou steel blast furnace slag powder, and 20 parts of stainless steel slag powder according to weight percentage. Add it into a mixer and mix evenly to obtain the rare earth-containing additive.

[0037] (2) Weigh 10 parts of rare earth additives, 45 parts of gold tailings, 23 parts of fly ash, 15 parts of quartz sand, 3 parts of borax, and 4 parts of sodium carbonate by weight percentage. Then add the weighed rare earth-containing additive, gold tailings, fly ash, quartz sand, borax, sodium carbonate into a mixer and mix evenly to obtain a mixture.

[0038] (3) Send the mixed material into the melting furnace through an automatic feeder, and the mixed material is melted at 1350° C. to obtain molten glass.

[003...

Embodiment 3

[0043] Embodiment 3: a kind of rare earth slag glass ceramics and its preparation method, its manufacture method is as follows:

[0044] (1) Preparation of rare earth-containing additives. Weigh 60 parts of Baiyun Obo secondary beneficiation tailings, 24 parts of Baotou steel blast furnace slag powder, and 16 parts of stainless steel slag powder according to weight percentage. Add it into a mixer and mix evenly to obtain the rare earth-containing additive.

[0045] (2) Weigh 15 parts of additives, 30 parts of lead-zinc tailings, 20 parts of iron tailings, 15 parts of fly ash, 10 parts of quartz sand, 4 parts of borax, and 6 parts of sodium carbonate by weight percentage. Then add the weighed rare earth-containing additives, lead-zinc tailings, fly ash, quartz sand, borax, and sodium carbonate into a mixer and mix evenly to obtain a mixture.

[0046] (3) Send the mixed material into the melting furnace through an automatic feeder, and the mixed material is melted at 1320° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com