Ultraviolet-light crosslinked polyethylene wire-cable material and preparation method thereof

A technology for cross-linking polyethylene, wire and cable materials, applied in plastic/resin/wax insulators, organic insulators, etc., can solve problems such as decreased cross-linking efficiency, pollution of reflectors and UV lamps, and impact on workshop production environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

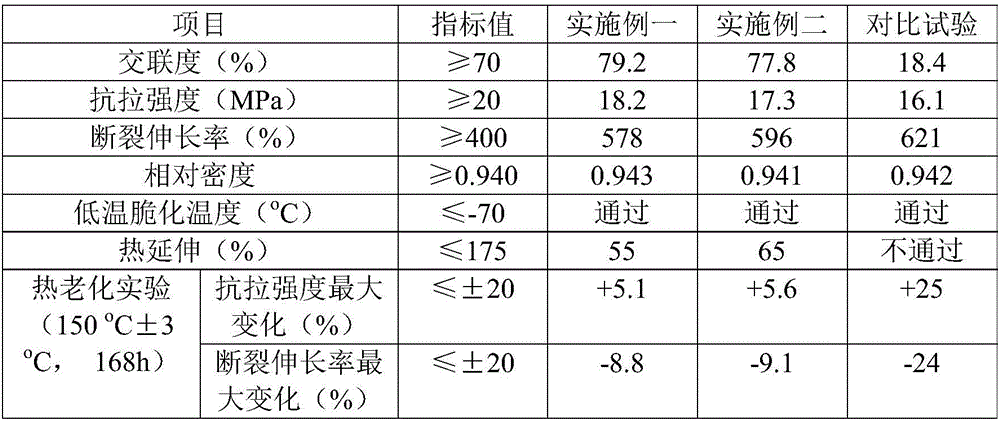

Examples

Embodiment 1

[0022] In this embodiment, the ultraviolet light cross-linked polyethylene wire and cable material and the preparation method thereof are carried out according to the following steps:

[0023] 1. Weigh 90 parts by weight parts of linear low density polyethylene (7042), 10 parts of high density polyethylene (5000S), 1.8 parts of 4-chlorobenzophenone, 1.2 parts of TAC, 1.3 parts of crosslinking accelerator N_N '─Methylene bisacrylamide, 0.1 part of transparent agent dibenzylidene sorbitol, 0.2 part of antioxidant 1010 and 0.1 part of TPP;

[0024] 2. Mix the above raw materials in a mixer at 250 rpm for 5 minutes to obtain a mixture;

[0025] 3. Preheat the extruder to 170°C, put the mixture obtained in step 2 into the mixture, so that the mixture is fully plasticized, extruded and cooled in the water tank, and then enter the ultraviolet radiation cross-linking equipment for irradiation. For 3s, the cross-linked polyethylene wire and cable irradiated by ultraviolet light is obtained. ...

Embodiment 2

[0027] 1. Weigh 100 parts of linear low-density polyethylene (7042), 1.2 parts of BDK, 1.2 parts of TMPTA, 1.0 part of crosslinking accelerator N_N'─methylene bisacrylamide, and 0.1 part of transparent agent HPN-20E in parts by weight , 0.3 part of antioxidant 1010 and 0.1 part of DLTP;

[0028] 2. Mix the above raw materials in a mixer at 250 rpm for 5 minutes to obtain a mixture;

[0029] 3. Preheat the extruder to 165°C, put the mixture obtained in step 2 into the mixture, so that the mixture is fully plasticized, extruded and cooled in the water tank; then enter the ultraviolet radiation crosslinking equipment for irradiation, irradiation For 3s, the cross-linked polyethylene wire and cable irradiated by ultraviolet light is obtained.

[0030] Comparative test (the crosslinking accelerator and transparent agent are not added to the raw materials of this comparative test, and the remaining raw materials are the same as in Example 2)

[0031] 1. Weigh 100 parts of linear low densit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com