Steelmaking device with co2 and co-ar cycle injection in the tail gas of vod furnace

A technology of tail gas circulation and CO2, which is applied in the field of iron and steel metallurgy, can solve the problems of extended smelting cycle, increased production cost, and decreased gas separation efficiency, achieving significant economic and social benefits, reducing smelting costs per ton of steel, and reducing the difficulty of preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

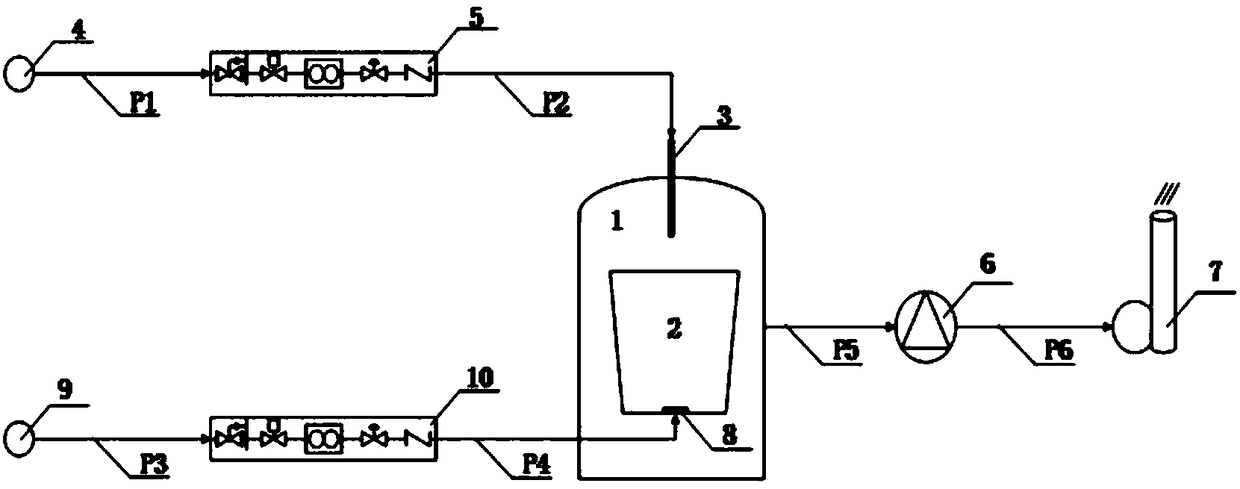

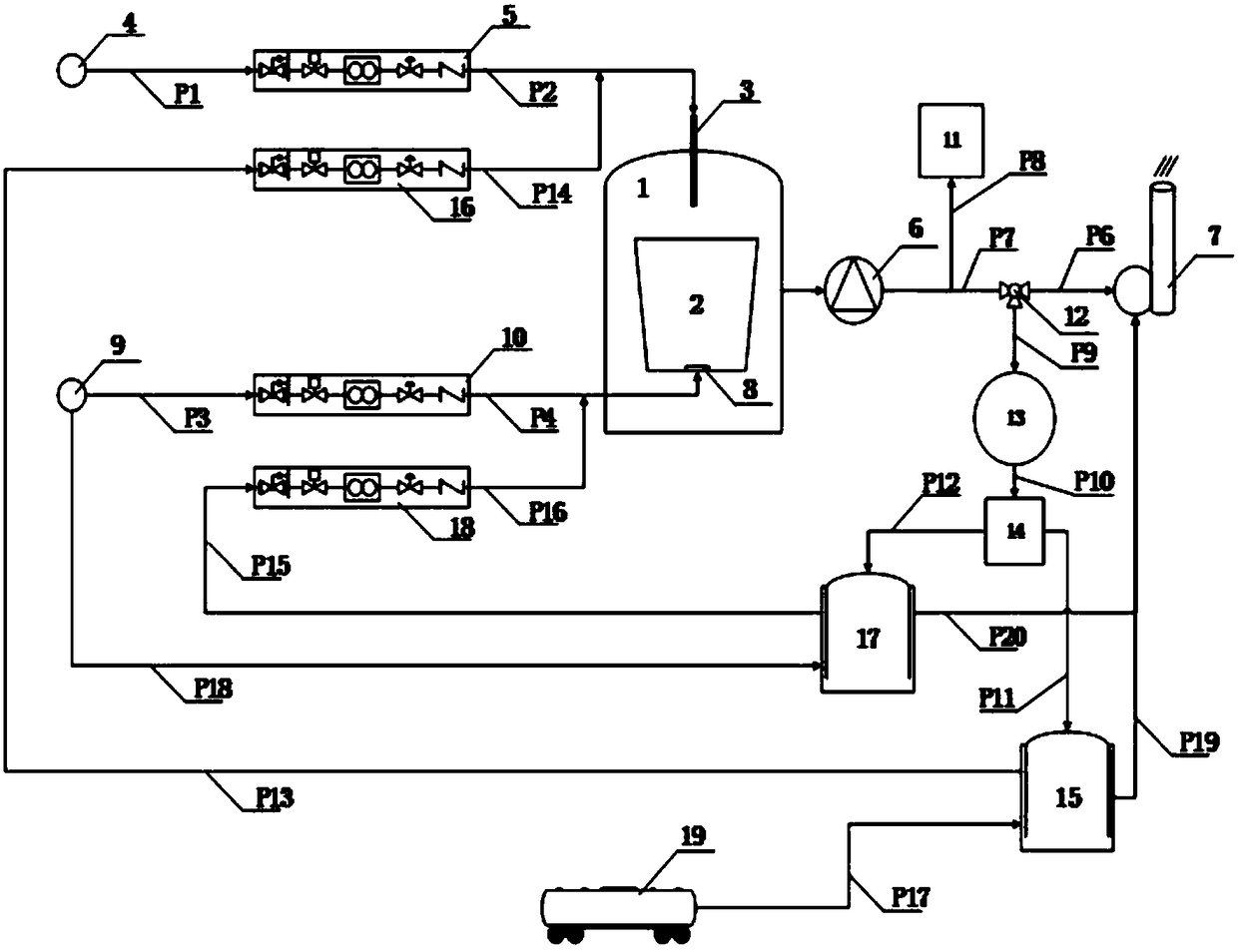

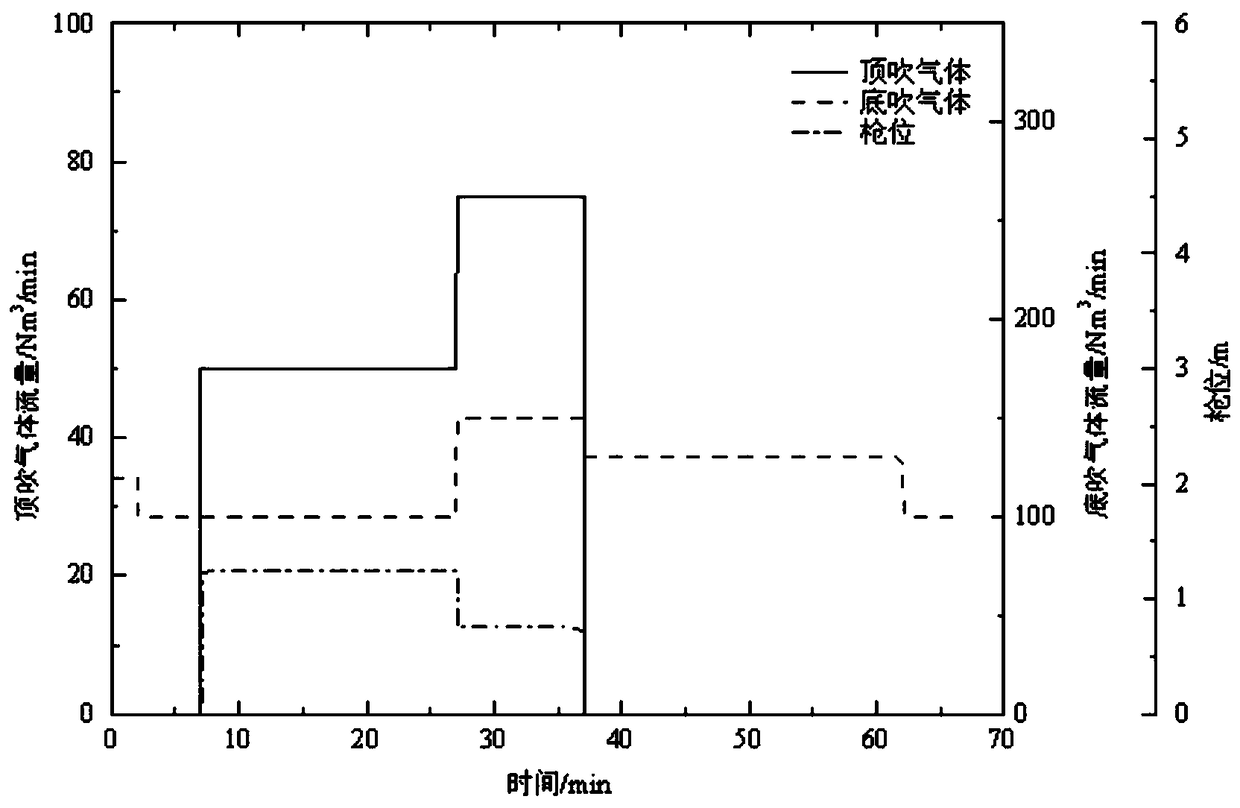

[0047] The invention is applied to 120t VOD refining furnace, top blowing O 2 -CO 2 Mixed gas, bottom blown Ar-CO mixed gas. As attached figure 2 The connection method of adding a new device and connecting, the basic requirements and main parameters of the device are:

[0048] Use mechanical vacuum pump; CO 2 The pressure in the gas storage tank is 1.5~2.0Mpa; CO 2 The maximum control flow of the flow control valve group is 100Nm 3 / min; The pressure in the CO-Ar mixed gas storage tank is 1.5~2.0Mpa; the maximum control flow of the CO-Ar mixed gas flow control valve group is 500NL / min; the gas analyzer is used to detect CO and CO in the exhaust gas 2 , Ar, O 2 And N 2 Concentration, monitoring accuracy is 0.5‰; gas compression separation adopts pressure swing adsorption method, which can separate tail gas into CO 2 Gas and CO-Ar mixture. CO 2 CO in air 2 Concentration is greater than 99.5%, pressure is greater than 1.5Mpa; O in CO-Ar mixture 2 The concentration is less than 0.01%...

Embodiment 2

[0056] The invention is applied to a 60t VOD vacuum refining furnace with top blowing O 2 -CO 2 Mixed gas, bottom blown Ar-CO mixed gas, according to the attached figure 2 The connection method of adding a new device and connecting, the basic requirements and main parameters of the device are:

[0057] Using steam jet vacuum pump; CO 2 The pressure in the gas storage tank is 1.8~2.0Mpa; CO 2 The maximum control flow of the flow control valve group is 60Nm 3 / min; The pressure in the CO-Ar mixed gas storage tank is 1.8~2.0Mpa; the maximum control flow of the CO-Ar mixed gas flow control valve group is 0~400NL / min; the gas analyzer is used to detect CO and CO in the exhaust gas 2 , Ar, O 2 And N 2 Concentration, monitoring accuracy is 0.5‰; gas compression separation adopts chemical adsorption method, which can separate tail gas into CO 2 Gas and CO-Ar mixture. CO 2 CO in air 2 Concentration is greater than 99.5%, pressure is greater than 1.5Mpa; O in CO-Ar mixture 2 The concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com