Single-impact surface nano-crystallization and gradient structure machining device

A gradient structure and processing device technology, applied in the field of material processing engineering, can solve the problems of unsuitable processing plane, limited application, low processing efficiency, etc., and achieve the effects of large impact force, reduced surface roughness, and long impact stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

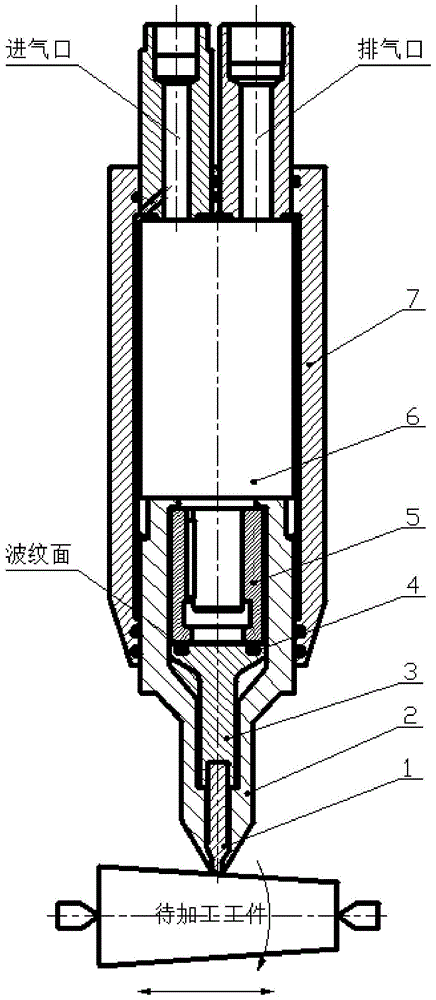

[0019] like figure 1 As shown, the mechanically driven surface nanometering device of the present invention includes a tool head 1 , a guide sleeve 2 , a transmission disc 3 , a wear-resistant ball 4 , a corrugated wear-resistant sleeve 5 , an air motor 6 , and a casing 7 .

[0020] In the guide sleeve 2, the tool head 1 is tightly fitted in the center hole of the drive disc 3, and reciprocates along the axis of the guide sleeve 2 together with the drive disc 3;

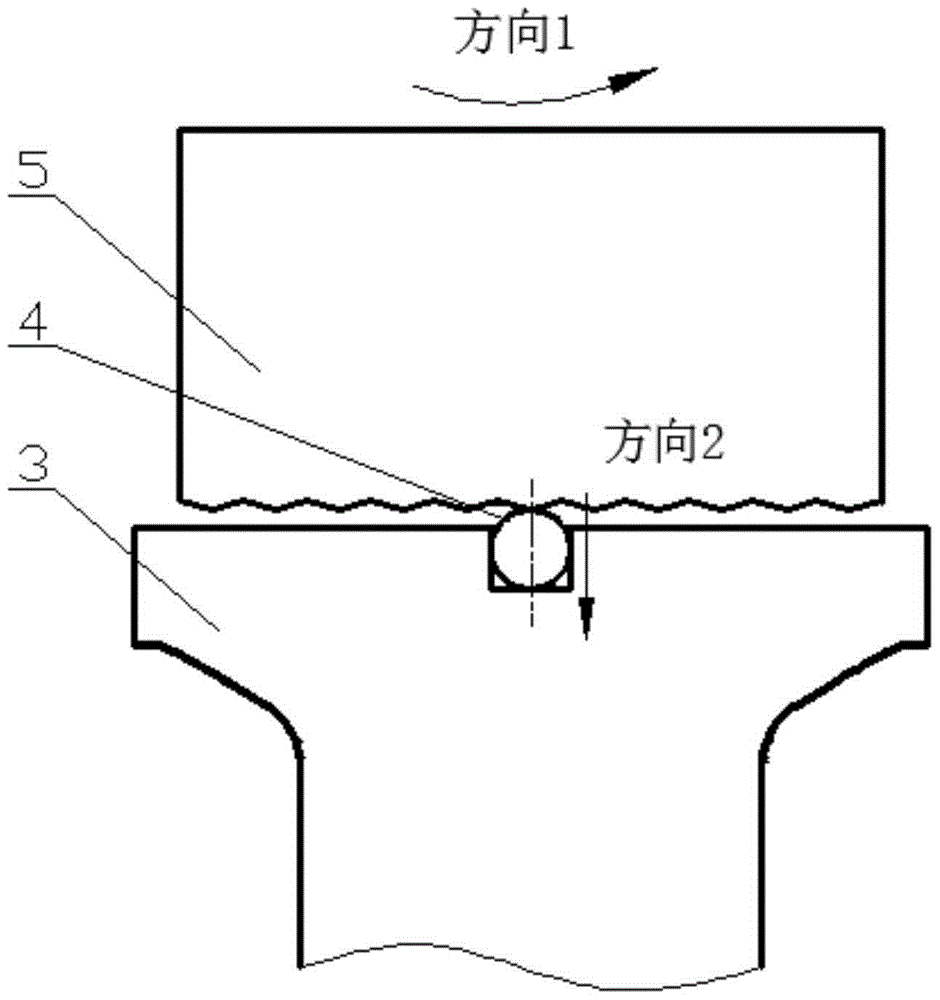

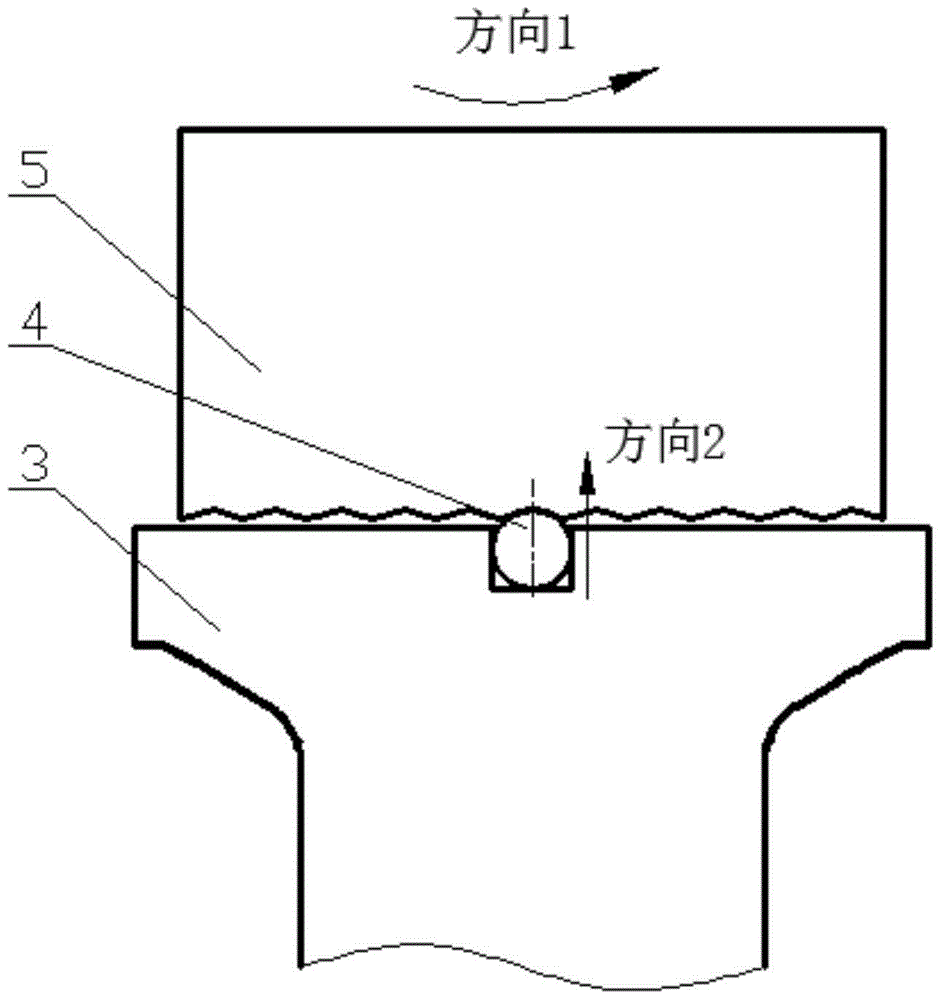

[0021] The wear-resistant balls 4 are evenly distributed in the radial holes of the transmission disc 3, and are in contact with the concave or convex surface of the corrugated surface of the corrugated wear-resistant sleeve 5; the corrugated wear-resistant sleeve 5 is installed on the output shaft of the air motor 6;

[0022] The guide sleeve 2 is fixedly connected with the air motor 6, and both are arranged in the inner cavity of the outer shell 7, and can reciprocate along the inner cavity of the outer shell 7

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com