Liquid spray electrotherapy room treated by coating carbon fibers and coating system thereof

A technology of carbon fiber and liquid mist, which is applied in the direction of textiles and papermaking, etc., can solve the problems of prepreg width that cannot meet the use requirements, high cost, and difficulty in prepreg manufacturing, and achieve high performance conversion rate, smooth surface, resin The effect of uniform content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

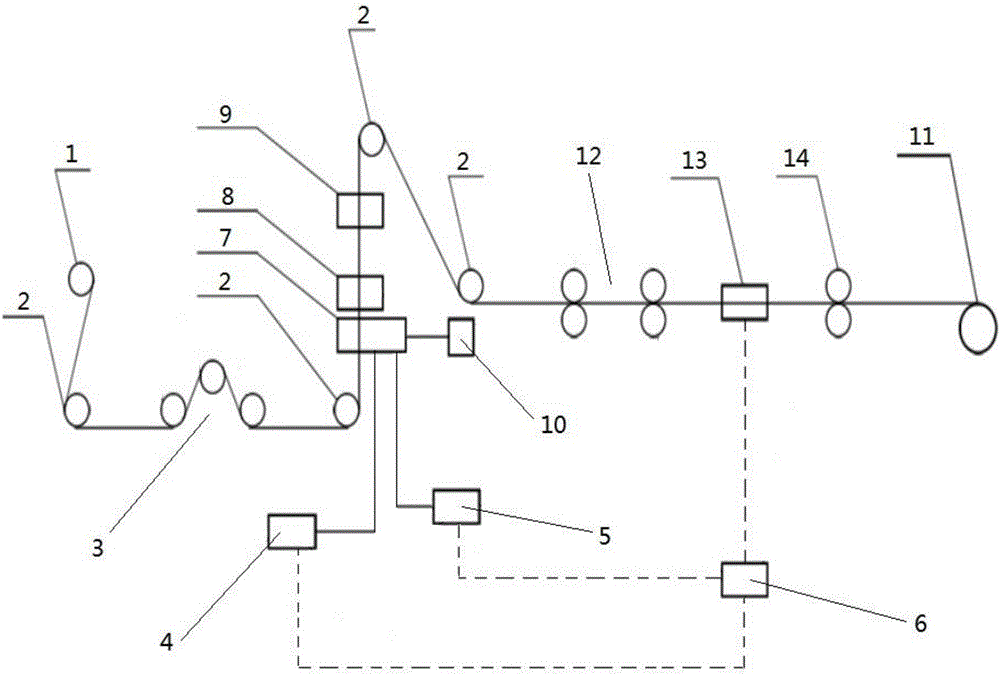

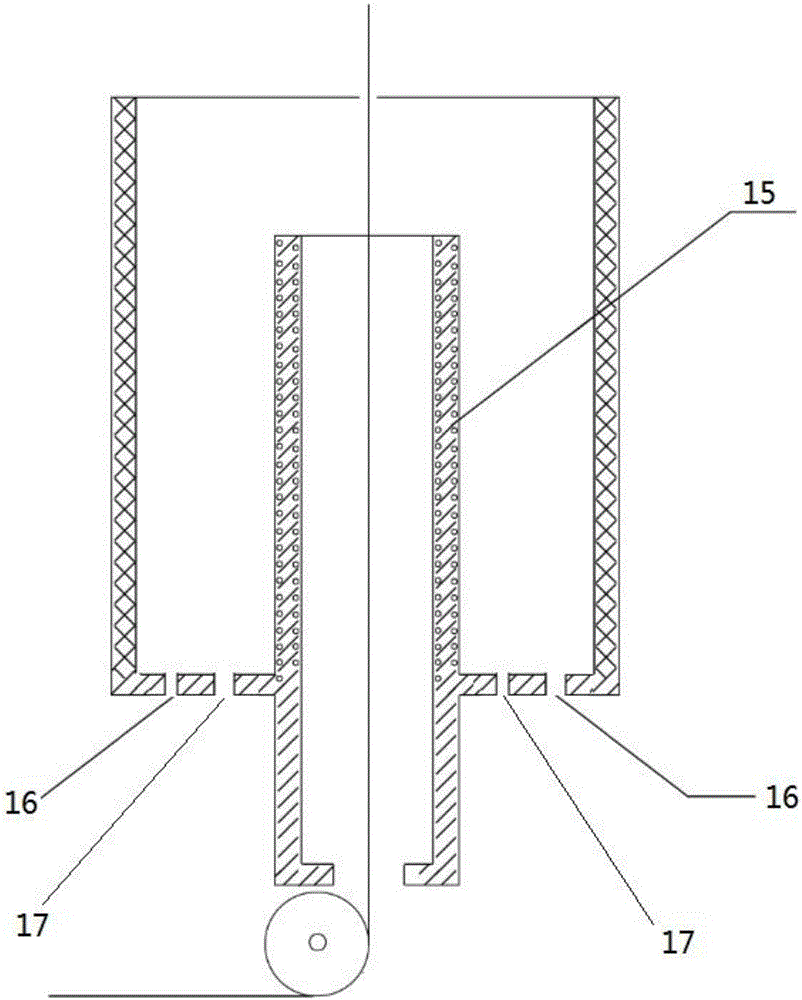

[0026] See attached Figure 1-2 , specifically provide a carbon fiber coating system based on liquid mist treatment, the carbon fiber coating system includes an uncoiling device 1, a plurality of guide rollers 2, a liquid mist delivery device 4, an air pump 5, a control system 6, a liquid mist electric Chamber 7, electrostatic coating chamber 8, melting furnace 9, electrostatic generator 10, winding device 11, speed regulating device 12 and traction device 14; the carbon fiber cloth uncoiled by the uncoiling device 1 is introduced into the liquid mist by the guide roller 2 Electric chamber 7, the carbon fiber cloth that passes through the liquid mist electric chamber 7 enters the electrostatic coating chamber 8, and the carbon fiber cloth that passes through the electrostatic coating chamber 8 enters the melting furnace 9, and then the carbon fiber cloth is guided by the guide roller 2 into the line speed adjustment device 12, and passes through The carbon fiber cloth adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com