Asymmetric type on-line installing device and method for underwater three-stage separation system

A technology of three-stage separation and installation device, applied in the field of marine engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

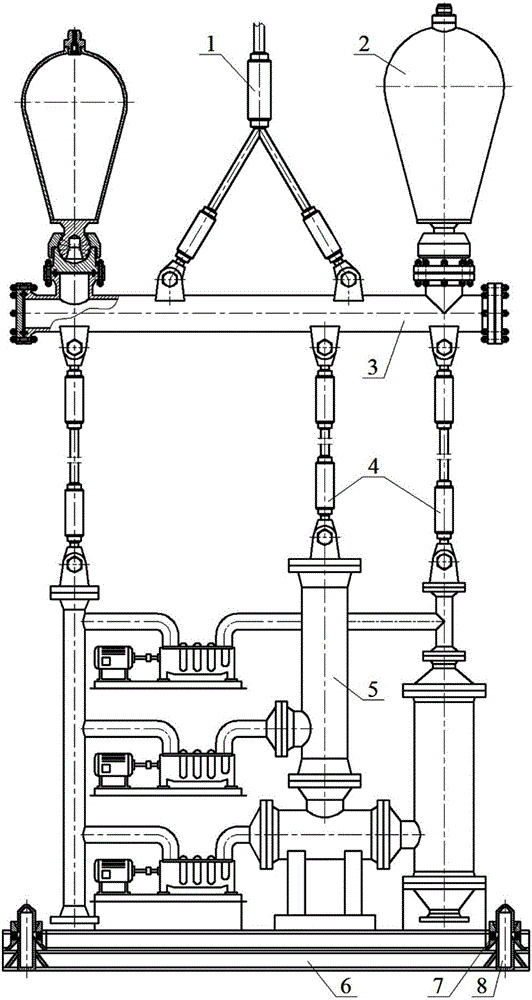

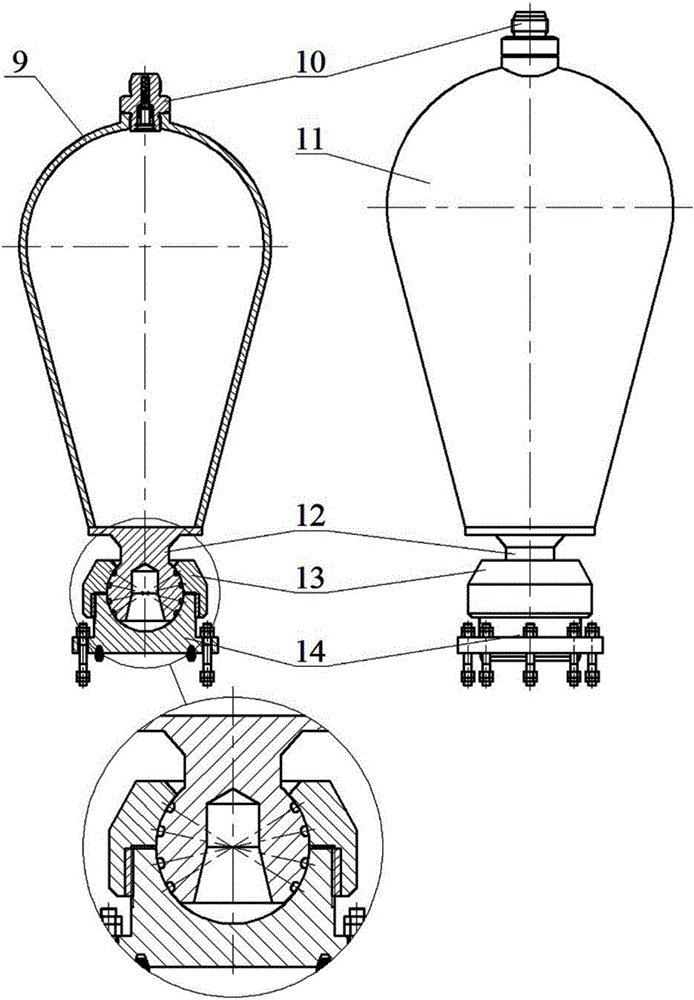

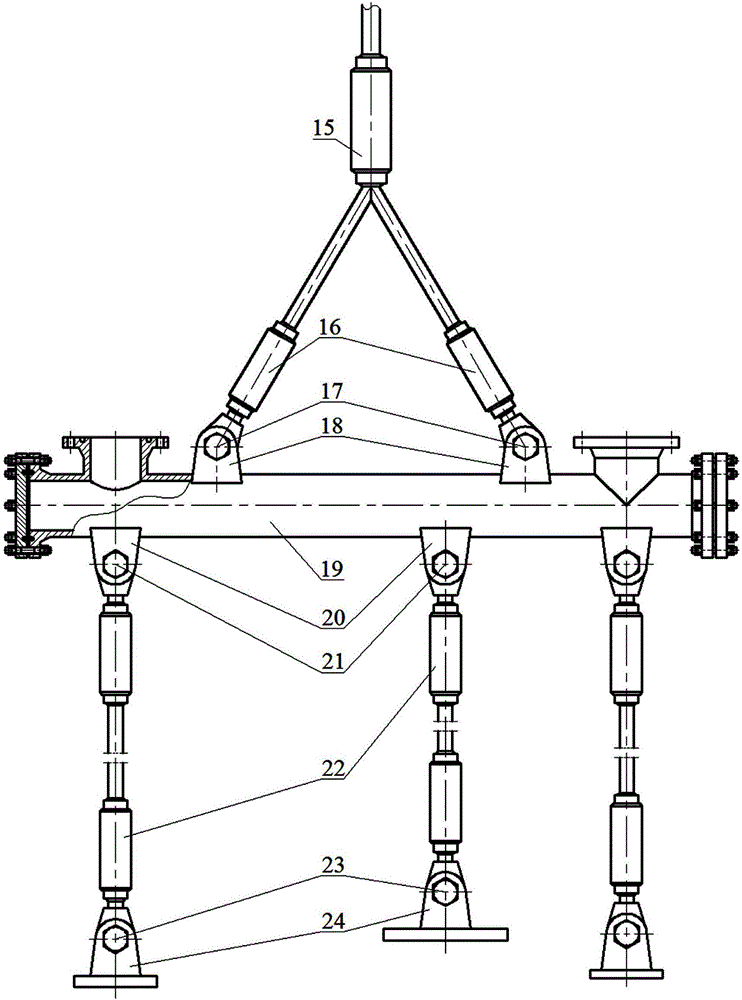

[0044] exist figure 1 Among them, the asymmetric online installation device of the underwater three-stage separation system is mainly composed of hoisting rigging 1, air cell body 2, balance pipe 3, connecting rigging 4, hoisting base 6, capture cylinder 7 and traction pipe 8, and its asymmetric The on-line installation method is to carry out the whole set of operation process of underwater manifold measurement and positioning operation, separation system hoisting operation, asymmetric centering operation, air cell balance pipe recovery operation and separation system docking operation in sequence, thus completing the underwater three In-line quick installation of stage separator 5.

[0045] exist figure 1Among them, before the assembly of the asymmetric online installation device, the outer surfaces of the main parts of the hoisting rigging 1 and the connecting rigging 4 are respectively coated with grease to prevent seawater corrosion, and the outer surfaces of the main par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com