Adjustable high-pressure/low-pressure EGR system for two-stage supercharged internal combustion engine and control method

A technology of two-stage supercharging and control method, applied in the direction of charging system, machine/engine, mechanical equipment, etc., can solve the problems of high manufacturing and maintenance costs, increased NOx emissions, difficult assembly, etc., to save cost and space , The effect of large EGR rate and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with the embodiment shown in the accompanying drawings, the technical solution of the present invention is further elaborated:

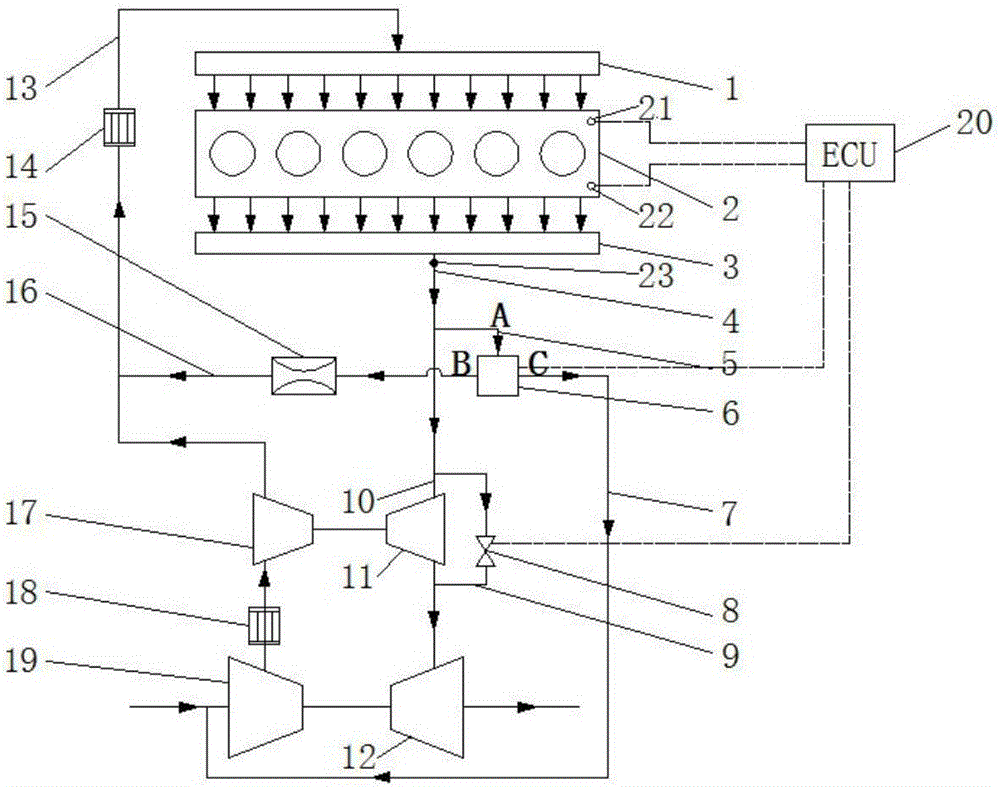

[0032] refer to figure 1, an adjustable high / low pressure EGR system and control method for a two-stage supercharged internal combustion engine, comprising: an electronic control unit ECU20, an internal combustion engine 2, and an intake manifold 13 connected to the intake port of the internal combustion engine 2 through an intake manifold 1 , the exhaust manifold 4 connected to the exhaust port of the internal combustion engine 2 through the exhaust manifold 3, the intake intercooler 14, the high-pressure stage compressor 17, the interstage intercooler 18, the low-pressure intercooler connected in sequence with the intake manifold 13 stage compressor 19, a high-pressure stage turbine 11 and a low-pressure stage turbine 12 that are sequentially communicated with the exhaust manifold 4, and an exhaust bypass pipeline 5 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com