Anti-freezing engine fuel pipe

A fuel pipe and engine technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as the inability to ensure the normal operation of vehicles, and achieve the effect of avoiding wax clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

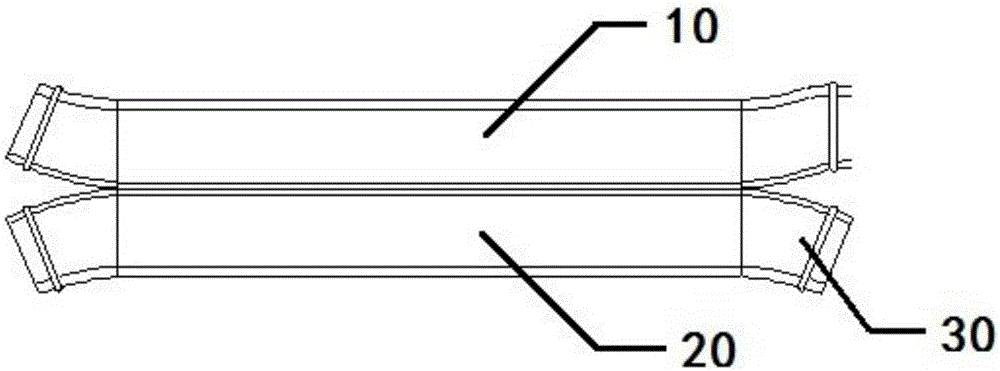

[0017] as attached figure 1 As shown, this embodiment relates to a kind of antifreeze engine fuel pipe, including oil return pipe and oil inlet pipe, wherein the oil return pipe and oil inlet pipe are made of copper, and the oil return pipe and oil inlet pipe are connected together by welding to form 8 A figure-shaped pipeline; in the 8-shaped pipeline, the oil inlet pipe is located above the oil return pipe; the two ends of the oil inlet pipe and the oil return pipe are connected together by a flexible hose.

Embodiment 2

[0019] This embodiment relates to an antifreeze engine fuel pipe, including a fuel return pipe and an oil inlet pipe, wherein the oil return pipe and the fuel inlet pipe are made of copper, and the oil return pipe and the fuel inlet pipe are connected together by welding to form an 8-shaped pipe Road; in the 8-shaped pipeline, the oil inlet pipe is located above the oil return pipe; the two ends of the oil inlet pipe and the oil return pipe are connected together by a flexible hose. The oil return pipe and the oil inlet pipe are made of copper alloy, and the copper alloy includes: 1.2wt% Mg, 1.2wt% Mn and the balance copper.

Embodiment 3

[0021] This embodiment relates to an antifreeze engine fuel pipe, including a fuel return pipe and an oil inlet pipe, wherein the oil return pipe and the fuel inlet pipe are made of copper, and the oil return pipe and the fuel inlet pipe are connected together by welding to form an 8-shaped pipe Road; in the 8-shaped pipeline, the oil inlet pipe is located above the oil return pipe; the two ends of the oil inlet pipe and the oil return pipe are connected together by a flexible hose. The oil return pipe and the oil inlet pipe are made of copper alloy, and the copper alloy includes: 1.75wt% Mg, 0.5wt% Mn and the balance copper.

[0022] In the antifreeze engine fuel pipe of the present invention, the oil return pipe and the oil inlet pipe are reliably welded together, and the oil return pipe can play the role of preheating and heat preservation for the oil inlet pipe, thereby avoiding the wax deposition and blockage of the oil inlet pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com