Pneumatic-hydraulic control system for side-turning carriage

A pneumatic hydraulic and control system technology, applied in dump trucks, transport passenger cars, railway car body parts, etc., can solve the problems affecting the life of hydraulic components, hidden dangers, and inability to achieve, so as to ensure the stability of tipping and improve the life of components. , to avoid the effect of too fast extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

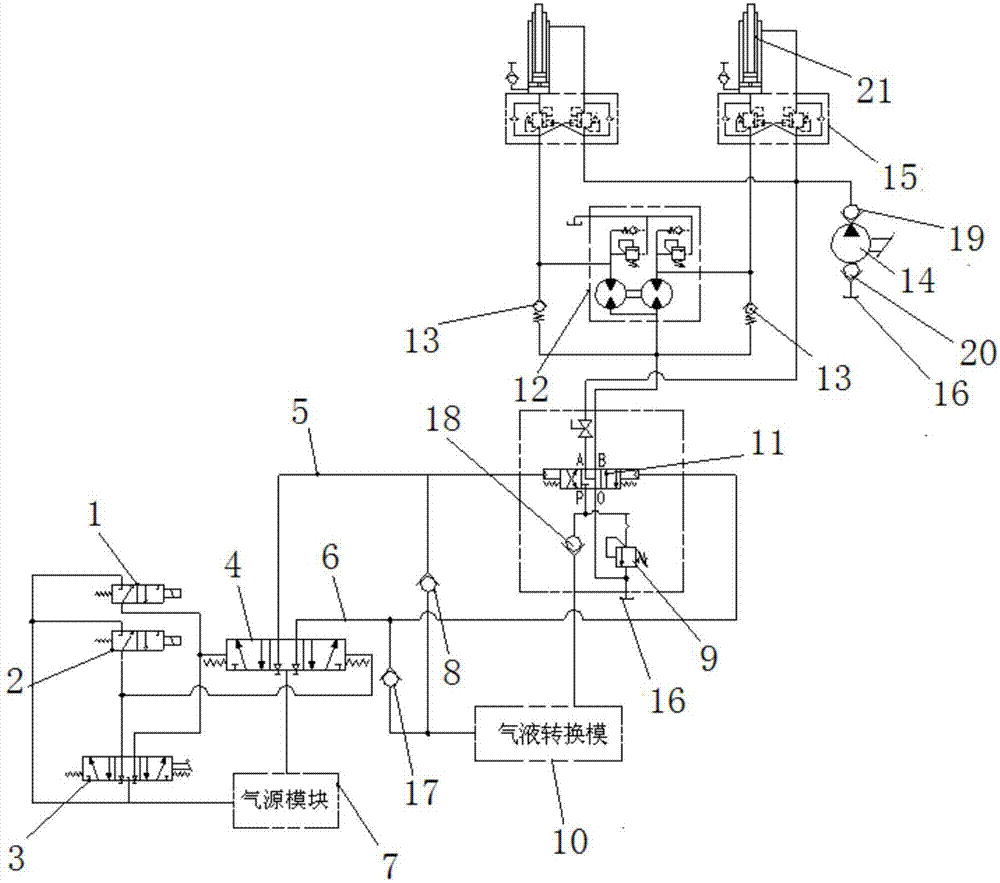

[0016] Such as figure 1 The pneumatic-hydraulic control system for the rollover carriage shown in the figure includes a carriage lift control solenoid valve 1, a carriage position control solenoid valve 2, a manual valve 3, a three-position reversing valve 4, a first control air circuit 5, and a second control valve. Control air circuit 6, air source module 7, gas-liquid conversion module 10, three-position four-way valve 11, synchronous motor oil supply module 12, hand oil pump 14, multiple carriage turnover operation cylinders 21 and the number of carriage turnover operation cylinders 21 Corresponding multiple balance valve modules 15 (the balance valve module 15 is used for reverse throttling, that is, the oil cylinder is under normal pressure, and when the oil cylinder is abnormally pulled during unloading, the valve will start throttling to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com