Liquid-cooled vertical heat conducting surface heat pipe radiator

A heat pipe radiator and heat conduction surface technology, which is applied in the direction of indirect heat exchangers, cooling/ventilation/heating renovation, lighting and heating equipment, etc., which can solve problems affecting normal work and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

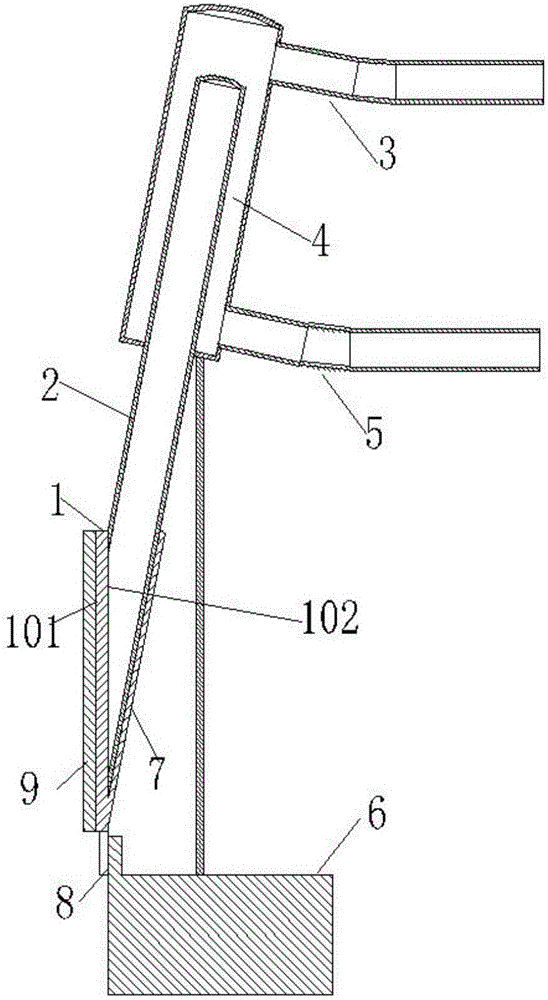

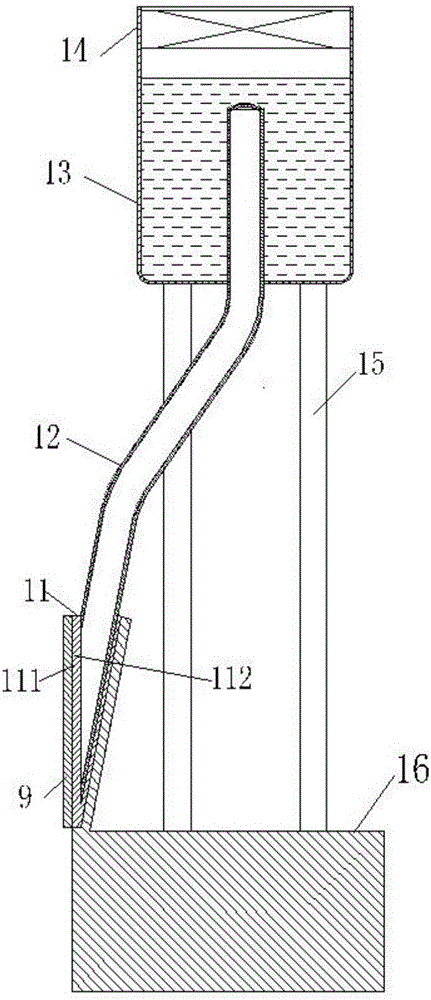

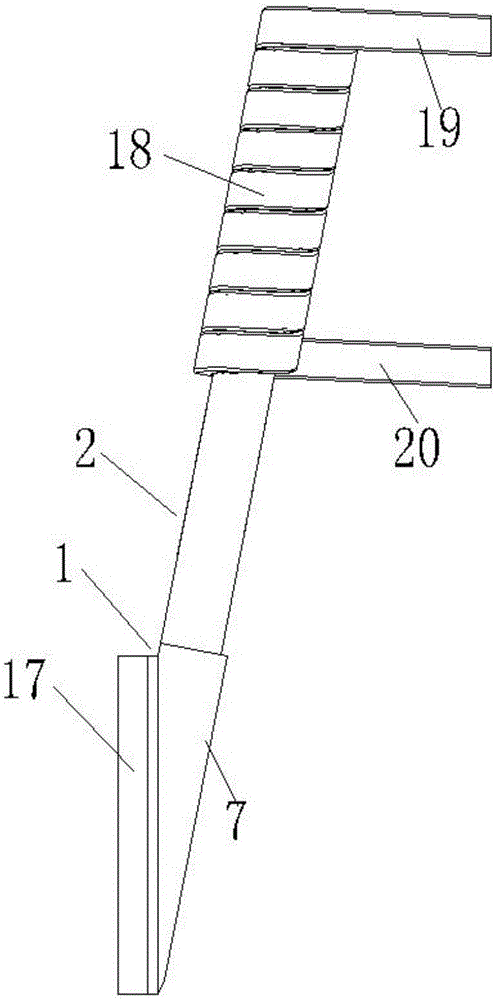

Embodiment 1

[0030] Example 1, Figure 12 It is a schematic diagram of embodiment 1, and the drawing is a cross-sectional view, and the cutting plane is a vertical plane parallel to the drawing through the central axis of the container 40; the inside of the container 40 needs to dissipate heat, and for this reason, a heat dissipation and ventilation device is provided in the container top space 42, and the container The upper part of the housing is also provided with cooling fins 41, but because the container is relatively high and the heat is relatively large, the bottom of the container also needs to use the vertical side 43 of the container to dissipate heat; for this reason, a liquid-cooled vertical heat-conducting surface heat pipe radiator is adopted. Radiator assembly 10 among the figure is to include figure 2 The combination of all parts of the middle heat pipe assembly, the heat dissipation surface 43 of the container 40 and the heat conduction surface of the heat conduction bloc...

Embodiment 2

[0031] Example 2, Figure 13 is a schematic diagram of embodiment 2, Figure 14 yes Figure 13 The A-A sectional view of the figure; the electrical cabinet 60 in the figure works in a relatively harsh environment, such as outdoors, so the shell 65 adopts a fully enclosed structure to strengthen protection; the circuit board 61 is installed vertically (other components on it are omitted and not shown) , due to the high heat of the heating element, a liquid-cooled vertical heat-conducting surface heat pipe radiator 64 (radiator assembly) is used for heat dissipation, wherein the area of the heat-conducting surface of the heat-conducting block 63 in the evaporating section in the contact direction with the working object ≥ the heating element The area of the heat dissipation surface 62 is kept in close contact with the entire area, and the contact surface is coated with heat-conducting silicone grease; the condensation section of the heat pipe surrounds the spiral cooling li...

Embodiment 3

[0032] Example 3, Figure 15 It is a schematic diagram of embodiment 3, and the drawing is a sectional view, and the sectional plane is a vertical plane passing through the central axis of the heat pipe 74 parallel to the drawing, and its external equipment and Figure 12 The same as shown; the electrical cabinet 70 in the figure works in a relatively harsh environment, such as outdoors, so the shell 75 adopts a fully enclosed structure to strengthen protection; the circuit board 71 is installed vertically (other components on it are omitted and not shown) , due to the high heat of the heating element, a liquid-cooled vertical heat-conducting surface heat pipe radiator 74 (radiator assembly) is used for heat dissipation, wherein the area of the heat-conducting surface of the heat-conducting block 73 in the evaporating section in the contact direction with the working object ≥ the heating element The area of the heat dissipation surface 72, and keep the whole area in close ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com