Off-line washing system and method for waste heat power generating boiler

A technology for waste heat power generation and boilers, which is applied to boiler cleaning devices, flushing, and cleaning heat transfer devices. The effect of tube corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

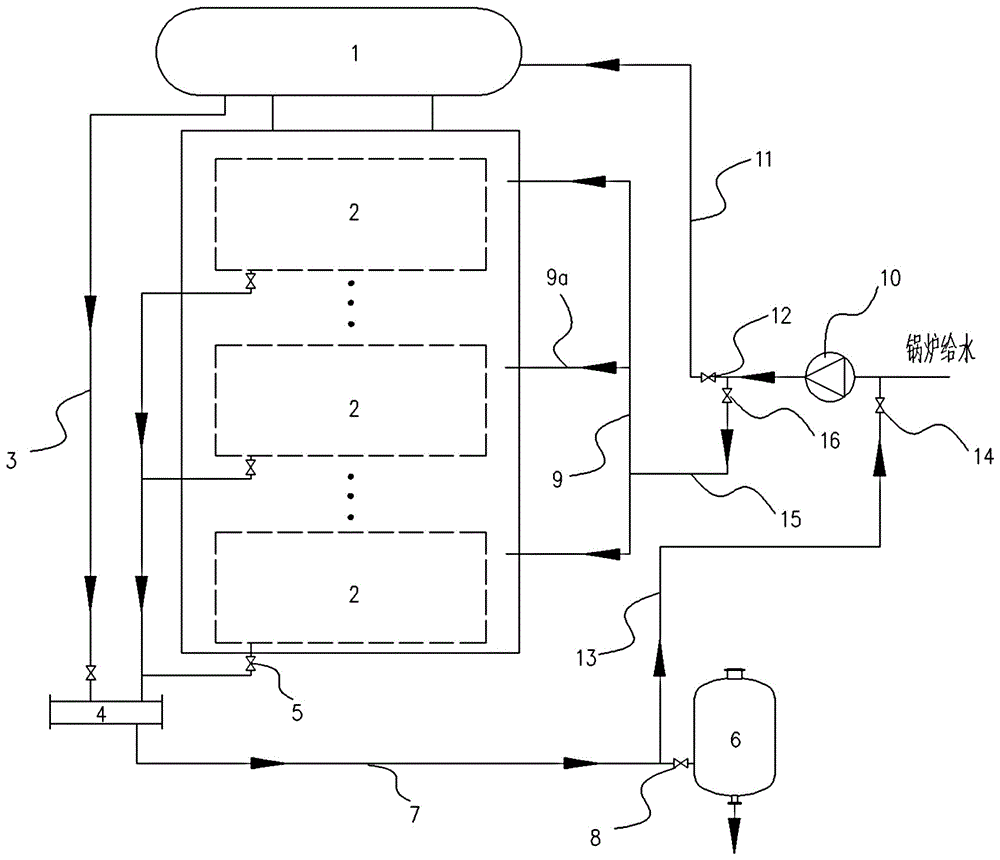

[0025] Such as figure 1 As shown, the present invention provides an off-line cleaning system for a waste heat power generation boiler. The boiler drum 1 and the heat exchange tube box 2 are respectively connected to the inlet of the sewage main pipe 4 through a set of sewage discharge pipes 3, and each sewage discharge pipe 3 is equipped with Sewage valve 5; the outlet of sewage main pipe 4 is connected with sewage expansion vessel 6 through connecting pipe 7, and the inlet of sewage expansion vessel 6 is provided with a first switch valve 8; heat exchange tube box 2 is connected to the main flushing water pipe through flushing water branch pipe 9a 9. The outlet of the boiler feed water pump 10 is connected to the inlet of the boiler steam drum 1 through the water supply pipe 11, and the second on-off valve 12 is provided on the water supply pipe 11; The other end is connected to the inlet of the boiler feed water pump 10, and a third on-off valve 14 is arranged on the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com