Transformer substation composite material bushing anti-seismic limit bearing capacity parameter calibration method

A technology of ultimate bearing capacity and composite materials, which is applied in the direction of testing material strength by applying repetitive force/pulsation force, analyzing materials, and testing material strength by applying stable bending force, etc. Low-level problems, to achieve the effect of ensuring the validity of the results, simplifying the test process, and saving test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

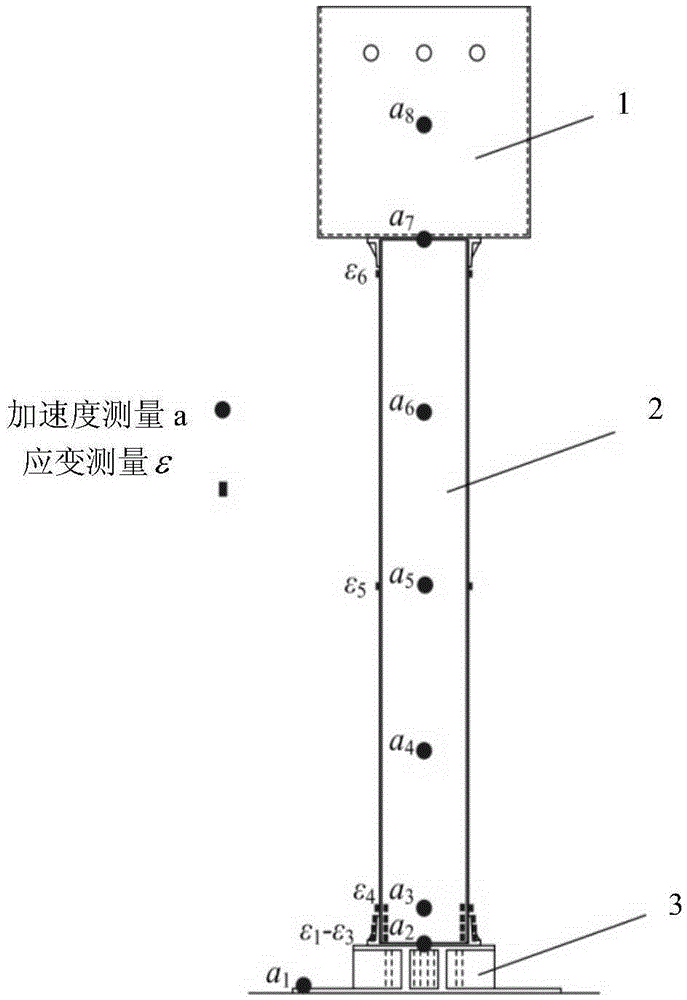

[0048] The invention of this example provides a method for calibrating the parameters of the seismic ultimate bearing capacity of the composite casing of the substation, including:

[0049] 1) For the first batch of composite casings of a certain specification, the earthquake simulation shaking table test and the pseudo-static bending test are carried out respectively, and the seismic ultimate bearing capacity Mse and the bending ultimate bearing capacity Mst are respectively obtained, and the conversion factor is calculated

[0050] r = Mse / Mst

[0051] 2) For the non-first batch of composite casing products of a certain specification, only the quasi-static bending test can be carried out, and the seismic ultimate bearing capacity Mse'=r*Mst' can be obtained through the conversion factor.

[0052] The basis of the above-mentioned carrying capacity calibration method is now described. The failure mode of composite casing in substation under seismic load is generally bending f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com