Type selection method of industrial vertical stirring mill and type selection test closed circuit fine grinding system

A stirring mill and vertical technology, which is applied in the selection method of industrial vertical stirring mills and the closed-circuit fine grinding system of the selection test, which can solve the problems of high data in the selection process, dead angles, and errors in selection results. , to achieve the effect of simple and convenient operation, simple and compact structure, accurate and reliable measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

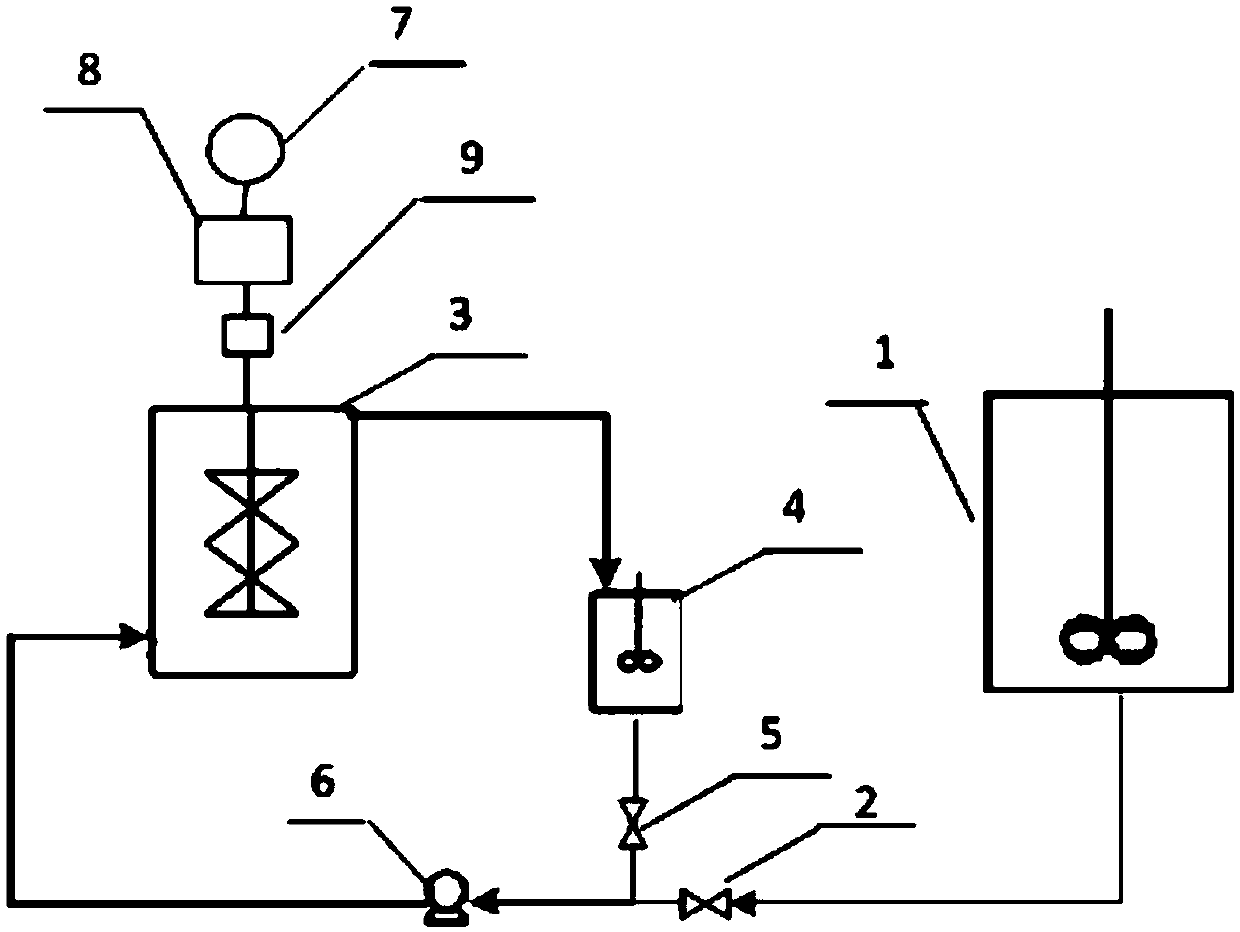

[0038] Such as figure 1 As shown, the type selection test closed-circuit fine grinding system of this embodiment includes an experimental vertical agitating mill 3 and a circulating device connected to form a closed-circuit circulating grinding system. The circulating device includes a slurry circulating tank 4 and a slurry circulating pump 6. The experimental type The overflow port on the upper part of the cylinder of the vertical mixing mill 3 is connected with the feed port of the slurry circulating tank 4, the discharge port of the slurry circulating tank 4 is connected with the inlet of the slurry circulating pump 6, and the outlet of the slurry circulating pump 6 is connected to the test type The vertical agitating mill 3 is connected to the feed inlet at the lower part of the cylinder, and the closed-circuit fine grinding system for the selection test is also equipped with a power measuring device for measuring the power of the agitating shaft of the experimental vertical...

Embodiment 2

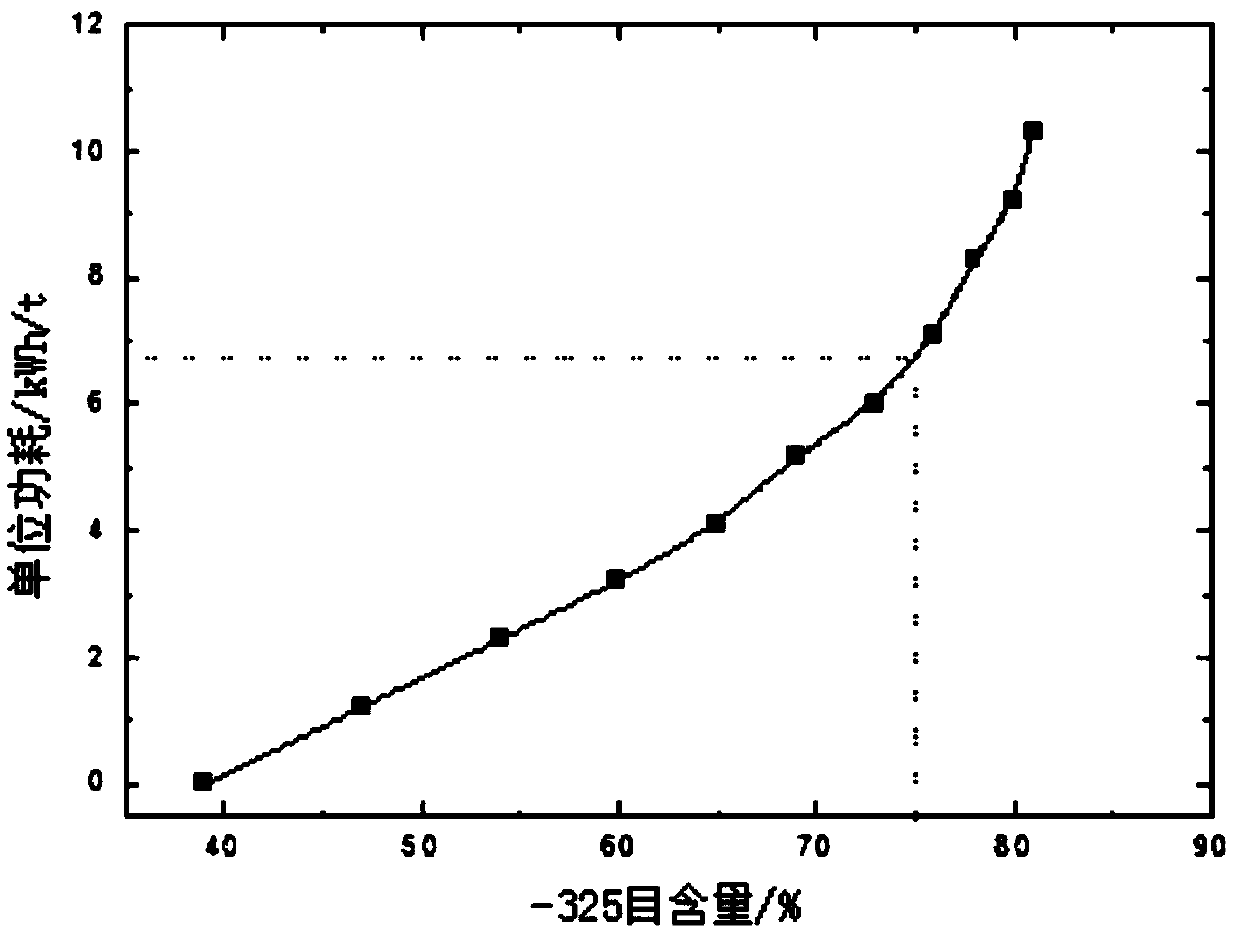

[0044] The grinding object of the industrial vertical stirring mill to be selected in this embodiment is molybdenum ore, which requires fine grinding to a target particle size of -325 mesh, and the target particle size mineral content is 75%.

[0045] The specific steps of the selection method are as follows:

[0046] (A) Prepare the type selection test closed circuit fine grinding system, the type selection test closed circuit fine grinding system is the type selection test closed circuit fine grinding system of Example 1;

[0047] (B) The ore powder to be ground is prepared into a slurry with a concentration of 65%, and the slurry is added to the experimental vertical agitating mill 3 in an amount of 120% of the cylinder volume of the experimental vertical agitating mill 3;

[0048] The specific steps of step (B) are:

[0049] 1) Ball allocation: Add the previously weighed and prepared media balls into the 9L experimental vertical agitating mill 3. The filling rate of the media balls ...

Embodiment 3

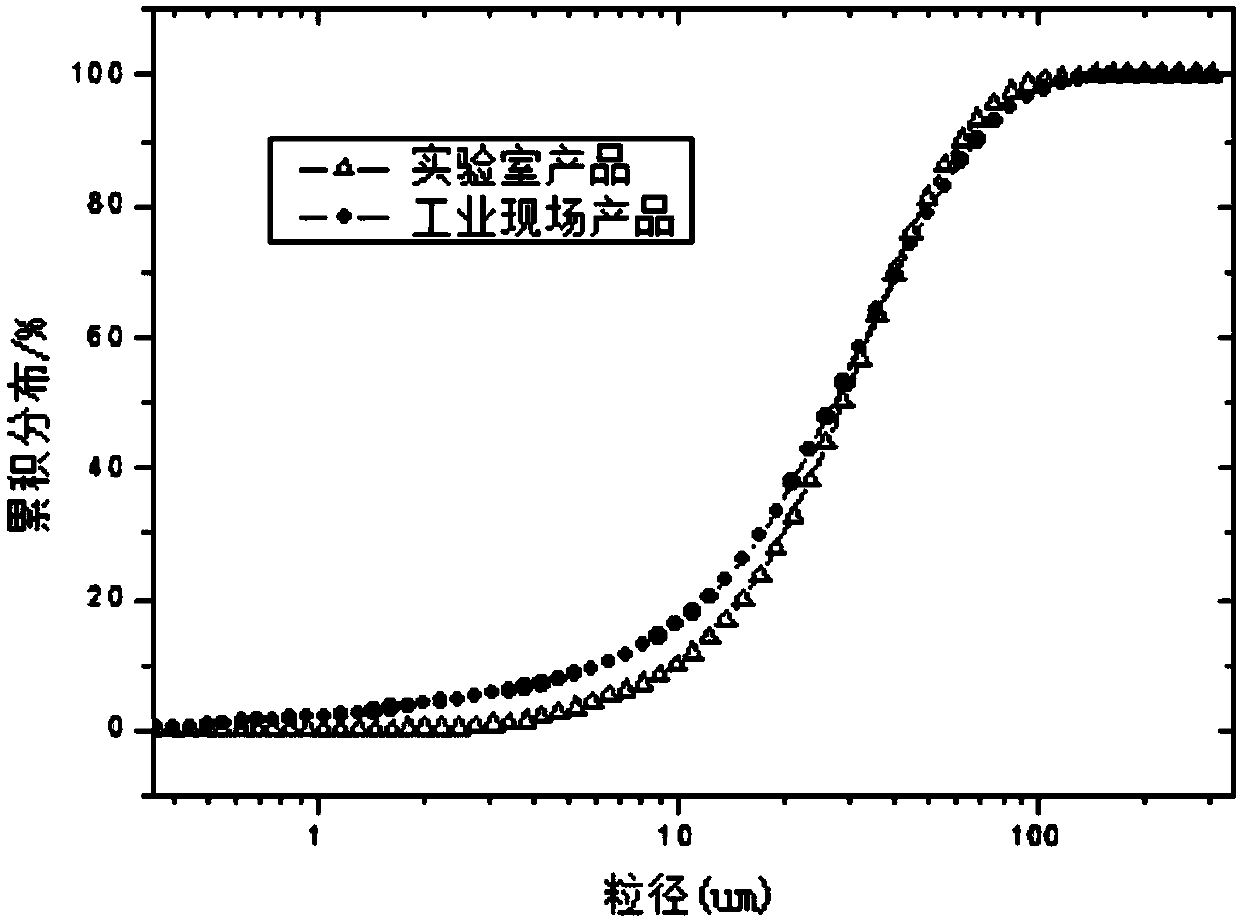

[0062] The grinding object of the industrial vertical agitating mill to be selected in this embodiment is iron ore, and it is required to be finely ground to a target particle size of -400 mesh, and the target particle size mineral content is 95%.

[0063] The specific steps of the selection method are as follows:

[0064] (A) Prepare the type selection test closed circuit fine grinding system, the type selection test closed circuit fine grinding system is the type selection test closed circuit fine grinding system of Example 1;

[0065] (B) The ore powder to be ground is prepared into a slurry with a concentration of 65%, and the slurry is added to the experimental vertical agitating mill 3 in an amount of 130% of the cylinder volume of the experimental vertical agitating mill 3;

[0066] The specific steps of step (B) are:

[0067] 1) Ball allocation: add the previously weighed and prepared media balls into the 50L experimental vertical agitating mill 3, the filling rate of the media ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com