Chewing simulation abrasion testing machine

A wear test and chewing simulation technology, applied in the direction of testing wear resistance, instruments, measuring devices, etc., can solve the problem of not being able to output the test piece in time, and achieve the effect of strong practicability, simple structure and reduction of instantaneous impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

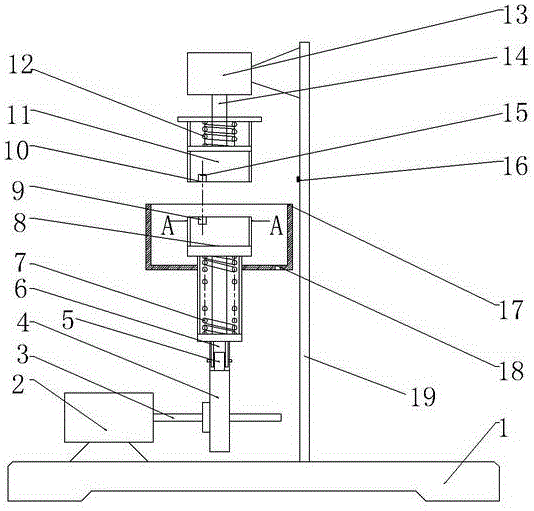

[0020] see figure 1 and figure 2 As shown, the present invention includes a mandibular simulation mechanism, an upper jaw simulation mechanism and a saliva tank;

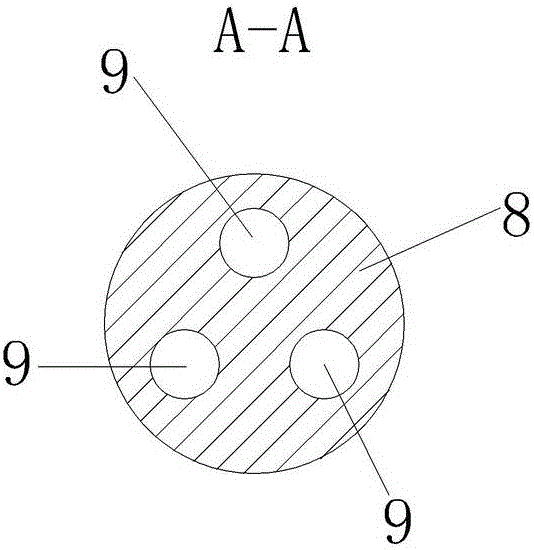

[0021] The mandibular simulation mechanism includes a variable frequency motor 2, a transmission shaft 3, a cam 4, a roller 5, a follower push rod 6, a first damping device 7 and a lower test piece table 8, and the variable frequency motor 2 is fixed on the frame 1 , the drive shaft 3 drives the cam 4 to rotate, and the motor torque is changed through stepless speed regulation to change the loading intensity. The roller 5 is hinged under the follower push rod 6, and the cam 4 can be in contact with the roller 5. The cam 4 drives the follower push rod 6 to reciprocate up and down through the roller 5, realizing the up and down movement of the mandible when chewing; the first damping device 7 is installed between the lower test piece platform 8 and the follower push rod 6, so as to reduce the instantaneous impulse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com