Machine tool vibration monitoring system and method based on LabView and single chip microcomputer

A vibration monitoring system and single-chip technology, applied in the field of machine tool vibration monitoring, can solve problems such as single function, aggravated vibration, and difficulty in realizing vibration prediction, and achieve the effects of optimizing machining parameters, improving machined surface quality, and reducing machine tool machining vibrations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

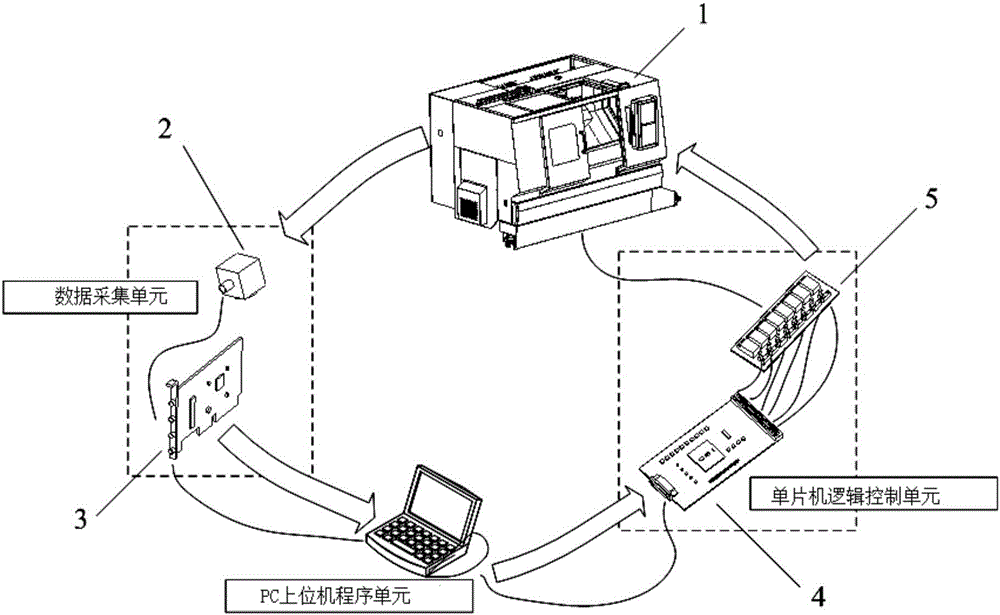

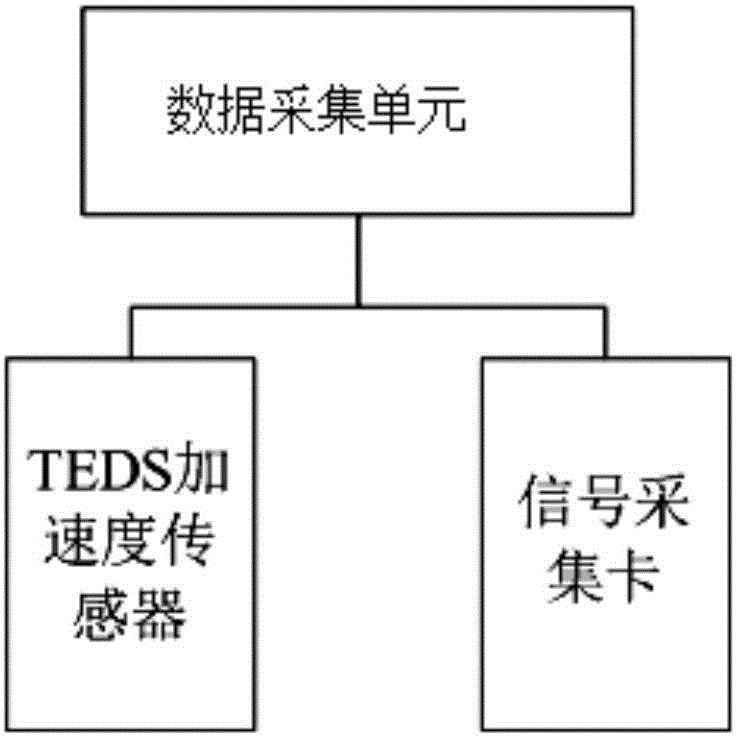

[0039] Such as figure 1 As shown, a kind of machine tool vibration monitoring system based on LabView and single-chip microcomputer of the present invention has data acquisition unit, PC upper computer program unit and single-chip computer logic control unit, wherein: the vibration data of data acquisition unit acquisition machine tool 1 is imported into PC upper computer program unit; PC upper computer program unit analyzes and calculates the vibration data of the machine tool, and outputs control instructions to the logic control unit of the single chip; Stop processing the signal, and the PLC program of the machine tool writes the signal into the designated memory for machine tool system operation.

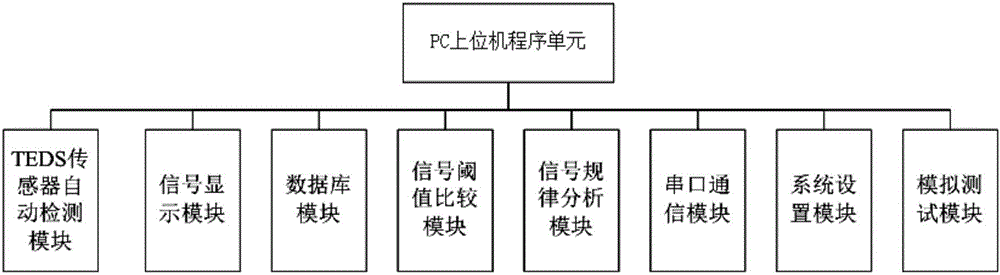

[0040] Such as figure 2 As shown, the PC upper computer program unit includes a TEDS sensor automatic detection module, a signal display module, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com