Ultrathin flexible capacitive touch sensor based on graphene and preparation method thereof

A touch sensor and flexible capacitor technology, applied in instruments, manufacturing tools, welding equipment, etc., can solve the problems of inability to achieve ultra-thin devices, increase in overall thickness, and inability to meet demands, achieve good flexibility, reduce difficulty, and improve quality. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

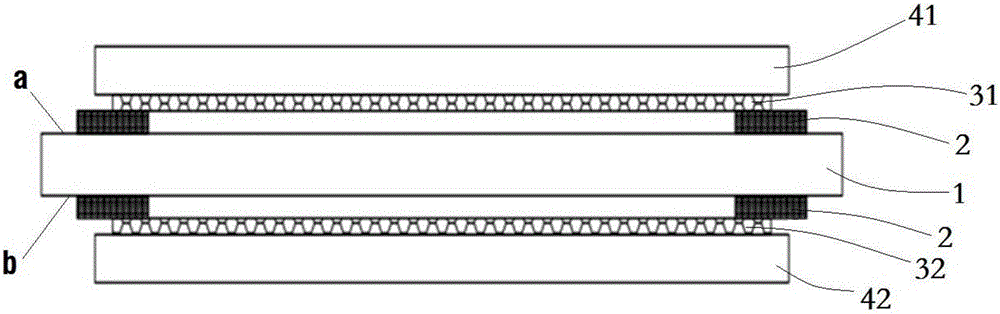

[0058] A graphene-based ultrathin flexible capacitive touch sensor in sheet form with a total thickness of 100 μm. include:

[0059] Ultra-thin flexible film 1, including a side and b side;

[0060] Both the a surface and the b surface are provided with channel electrodes 2;

[0061] The first conductive layer 31 arranged on the a surface, the first conductive layer 31 is connected to the capacitive sensing chip of the capacitive touch sensor through the channel electrode 2 of the a surface, and one end of the channel electrode 2 of the a surface is connected to the first One conductive layer 31 is overlapped together, and the other end extends to the capacitive sensing chip;

[0062] A first optical adhesive layer 41 disposed on the surface of the first conductive layer 31;

[0063] The second conductive layer 32 arranged on the b surface, the second conductive layer 32 is connected to the capacitive sensing chip of the capacitive touch sensor through the channel electrode...

Embodiment 2

[0076] A graphene-based ultrathin flexible capacitive touch sensor in sheet form with a total thickness of 100 μm. include:

[0077] Ultra-thin flexible film 1, including a side and b side;

[0078] Both the a surface and the b surface are provided with channel electrodes 2;

[0079] The first conductive layer 31 arranged on the a surface, the first conductive layer 31 is connected to the capacitive sensing chip of the capacitive touch sensor through the channel electrode 2 of the a surface, and one end of the channel electrode 2 of the a surface is connected to the first One conductive layer 31 is overlapped together, and the other end extends to the capacitive sensing chip;

[0080] A first optical adhesive layer 41 disposed on the surface of the first conductive layer 31;

[0081] The second conductive layer 32 arranged on the b surface, the second conductive layer 32 is connected to the capacitive sensing chip of the capacitive touch sensor through the channel electrode...

Embodiment 3

[0094] A graphene-based ultrathin flexible capacitive touch sensor in sheet form with a total thickness of 70 μm. include:

[0095] Ultra-thin flexible film 1, including a side and b side;

[0096] Both the a surface and the b surface are provided with channel electrodes 2;

[0097] The first conductive layer 31 arranged on the a surface, the first conductive layer 31 is connected to the capacitive sensing chip of the capacitive touch sensor through the channel electrode 2 of the a surface, and one end of the channel electrode 2 of the a surface is connected to the first One conductive layer 31 is overlapped together, and the other end extends to the capacitive sensing chip;

[0098] A first optical adhesive layer 41 disposed on the surface of the first conductive layer 31;

[0099] The second conductive layer 32 arranged on the b surface, the second conductive layer 32 is connected to the capacitive sensing chip of the capacitive touch sensor through the channel electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com