A Grain Size Prediction Method of Aluminum Alloy Die Castings Based on ga-elm Algorithm

A grain size, aluminum alloy technology, applied in geometric CAD, CAD numerical modeling, design optimization/simulation, etc., can solve problems such as low prediction efficiency, low prediction accuracy, and large impact on results, and improve prediction accuracy. rate, improve forecasting efficiency, and enrich the effect of model library

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

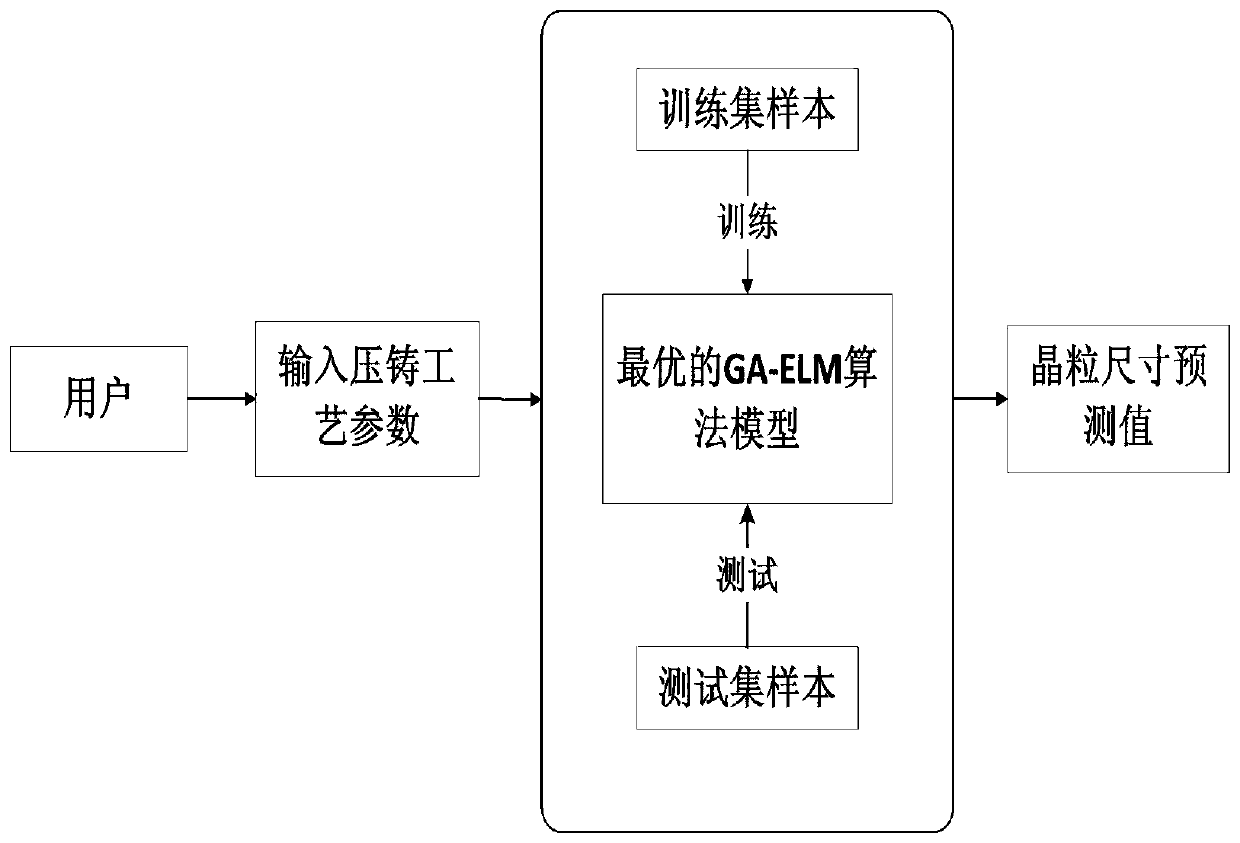

[0029] Embodiment: a method for predicting the grain size of aluminum alloy die castings based on the GA-ELM algorithm, the method comprises the following steps:

[0030] (1) There are many die-casting process parameters that affect the grain size of aluminum alloy die-casting parts. This method selects the four most influential process parameters as the mold preheating temperature, injection temperature, low-speed filling speed, and high-speed filling speed as input parameters. ;

[0031] (2) Obtain predicted data samples by means of software simulation or experiment, and divide the data samples into training set and test set;

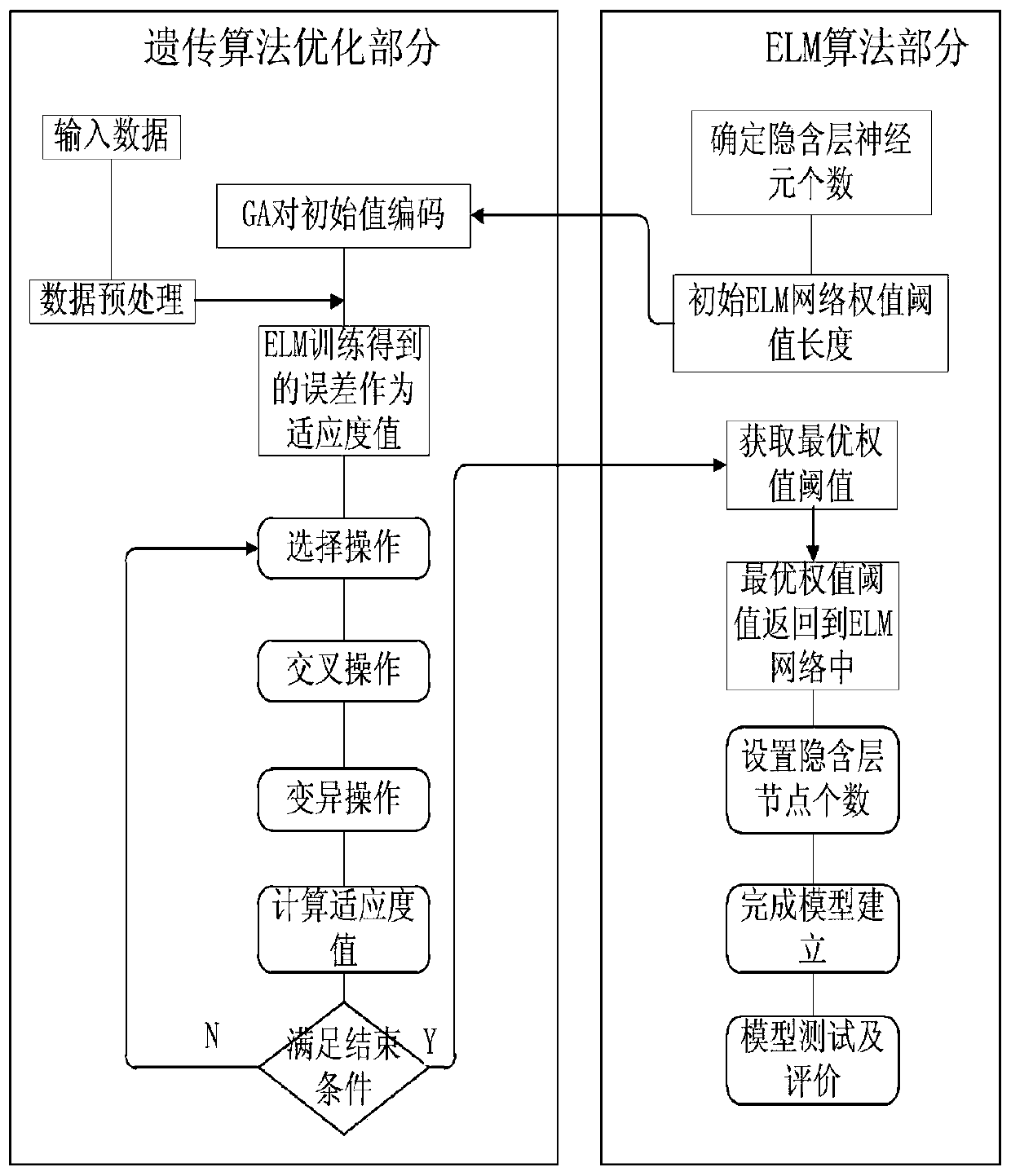

[0032] (3) Use the genetic algorithm (GA) to optimize the initial weight and threshold of the extreme learning machine (ELM), so as to obtain the new algorithm GA-ELM algorithm;

[0033] (4) Use the training set data samples obtained in step (2) to train the new GA-ELM algorithm in step (3), where the individual fitness value as the training effect e...

Embodiment 2

[0037] Example 2: Basic principles of ELM

[0038] ELM is a new type of feedforward neural network learning algorithm proposed by Nanyang Technological University professor Huang Guang Bin in 2006. Compared with the traditional single hidden layer feedforward neural network, it has high classification accuracy, good generalization ability, The advantages of less adjustment parameters.

[0039] The weight matrix of the input layer and the threshold matrix of the hidden layer of the ELM neural network are randomly generated, and there is no need to adjust them in subsequent operations. It can be seen from the theory that only the number of hidden layer nodes needs to be set to obtain the unique optimal solution.

[0040] For a given input sample, the output matrix of hidden layer neurons is calculated as

[0041] H=g(WX T +b) (1)

[0042] In the formula: W is the input layer weight matrix; b is the hidden layer threshold matrix; W and b are randomly generated.

[0043] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com