Sound absorption superstructure

A superstructure and sound-absorbing technology, which is applied in the direction of sound-generating equipment, building components, building structures, etc., can solve the problems of thick sound-absorbing materials, unfavorable air circulation, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

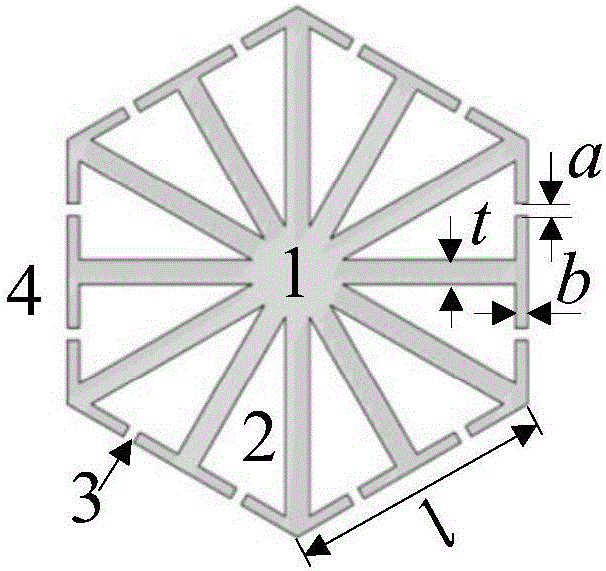

[0018] figure 1 A sound-absorbing superstructure unit cell is presented. The unit cell is a regular hexagon. 1 is the material area of the unit cell, which is a material with high rigidity (such as steel and aluminum alloy, etc.). The regular hexagonal unit cells are equally divided into 12 right triangles, and the inside of each right triangle is a right triangle acoustic cavity 2 . The right triangle acoustic cavity 2 communicates with the external sound field 4 through a short resonant tube 3 . The right triangle acoustic cavity 2 and the short resonant tube 3 form a Helmholtz resonant cavity.

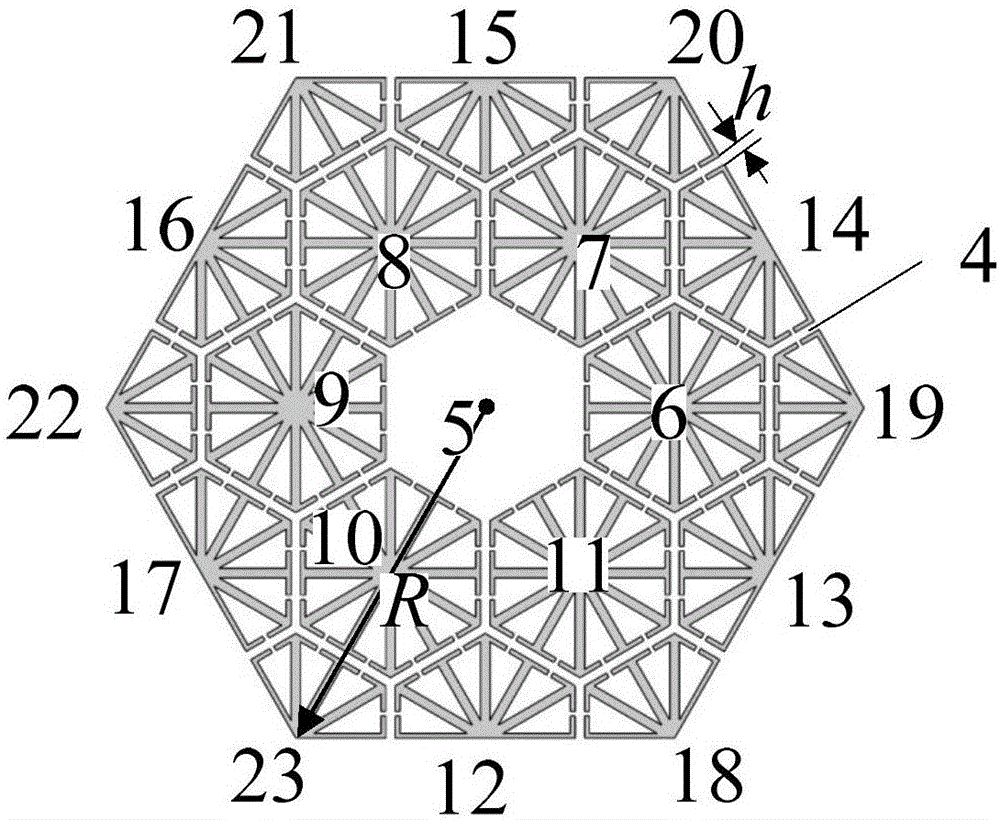

[0019] figure 2 A sound-absorbing superstructure is presented. The sound-absorbing superstructure is composed of regular hexagonal unit cells. 5 is a regular hexagonal air domain. The first outer layer of the regular hexagonal air domain 5 is 6 regular hexagonal unit cells, numbered 6, 7, 8, 9, 10 and 11 respectively. The boundary of each regular hexagonal unit cell is pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com