Controllable temperature disc structure provided with ceramic bush

A technology of ceramic bushing and surface structure, which is applied in the direction of gaseous chemical plating, coating, electrical components, etc., which can solve the problems of reduced reliability of equipment, affecting the level of thin film substrates, and prolonged shutdown and debugging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is further described in detail, but invention protection content is not limited to described embodiment:

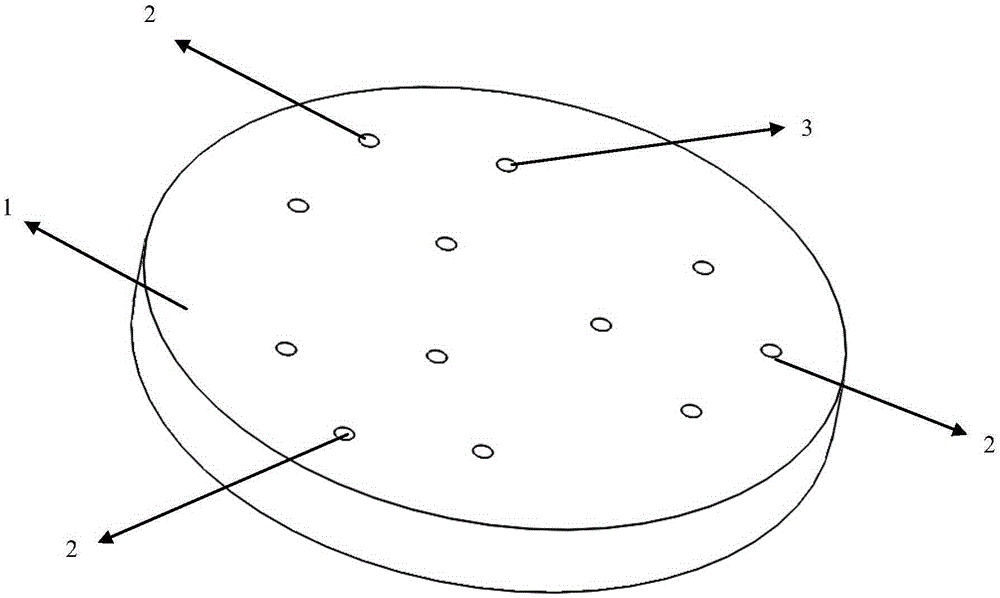

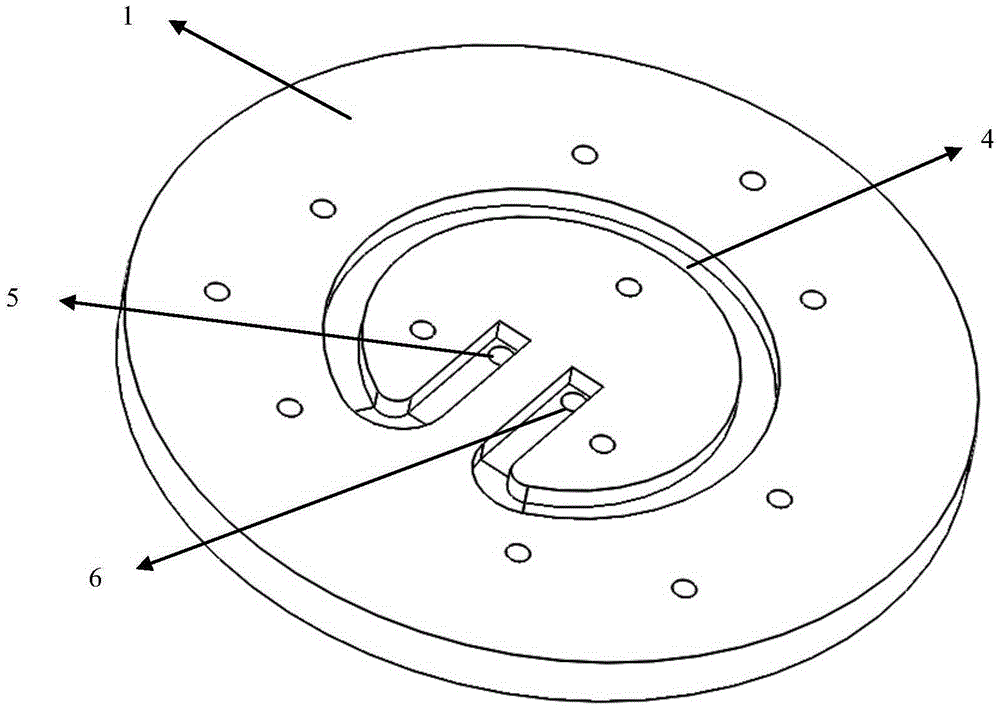

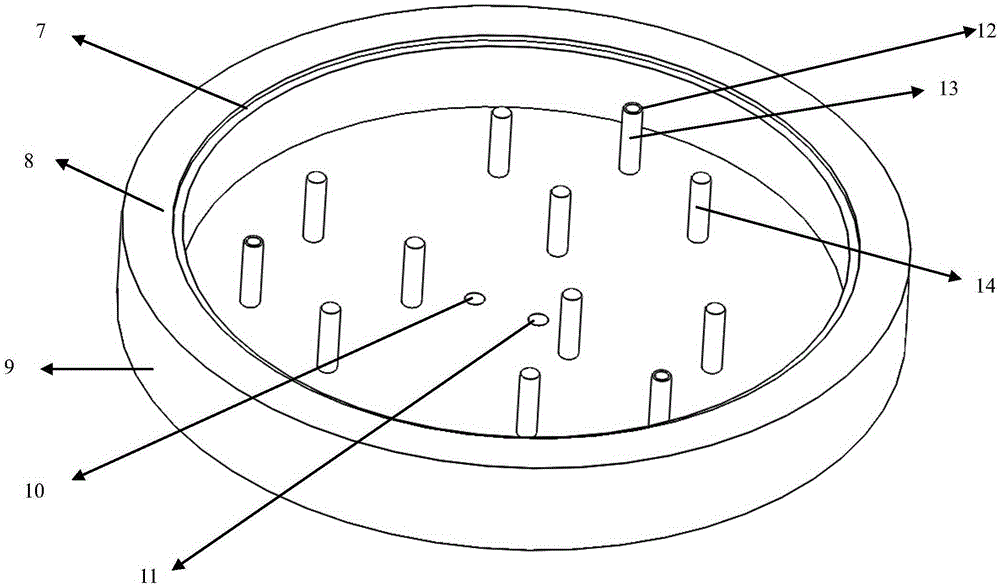

[0016] refer to Figure 1-4 , a temperature-controllable disk surface structure with a ceramic liner, the structure includes an aluminum plate 1 and a ceramic liner 9, the aluminum plate 1 is provided with three through holes A2 and nine through holes B3, the aluminum plate 1 There is also a heat transfer channel 4 inside. The heat transfer channel 4 is provided with an inlet 5 and an outlet 6; There are three jacking pin sleeves 13 corresponding to the positions of the above three through holes A2, each jacking pin sleeve 13 has a through hole C12, and the inside of the ceramic bushing 9 is also provided with the position corresponding to the nine through holes B3. Corresponding to the nine support columns 14, the bottom of the ceramic bushing 9 is provided with a hole A10 and a hole B11, the hole A10 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com