Rotary transformer and rotating body equipped with same

A rotary transformer and rotary body technology, applied in the field of transformers and rotary bodies, rotary transformers and rotary bodies, can solve problems such as increased risk of connection line failure, rotary transformer failure, complex manufacturing process, etc., to improve rapid response performance and prevent unfavorable Influencing and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

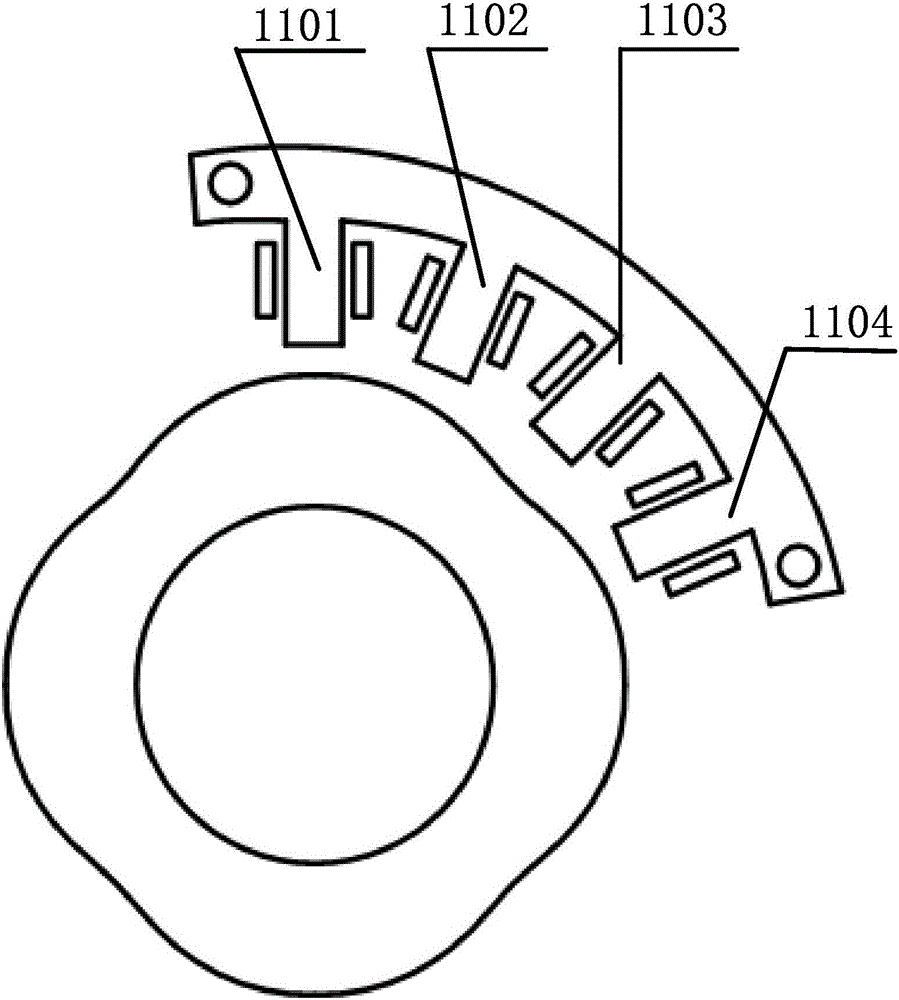

[0047] In this embodiment, K=1 and N=4, so the number of stator detection teeth of the resolver is 4, and the number of salient poles of the rotor is 4. figure 1 Shown is a schematic cross-sectional view of the stator and rotor of the resolver. The stator includes a stator yoke and stator detection teeth, the stator detection teeth are arranged on the stator yoke; the angle spanned by the stator yoke is less than 360 degrees, and the rotor includes a rotor core. Both the stator core and the rotor core are formed by stamping silicon steel sheets. In this embodiment, the 4 salient rotor poles are evenly distributed along the circumference of the rotor core surface, the 4 stator detection teeth are distributed along the circumferential surface of the stator yoke, and the 4 stator detection teeth are distributed clockwise along the circumference as 1101, 1102, 1103, 1104. The included angle between stator detection tooth 1101 and stator detection tooth 1102 is 22.5 degrees, the in...

no. 2 example

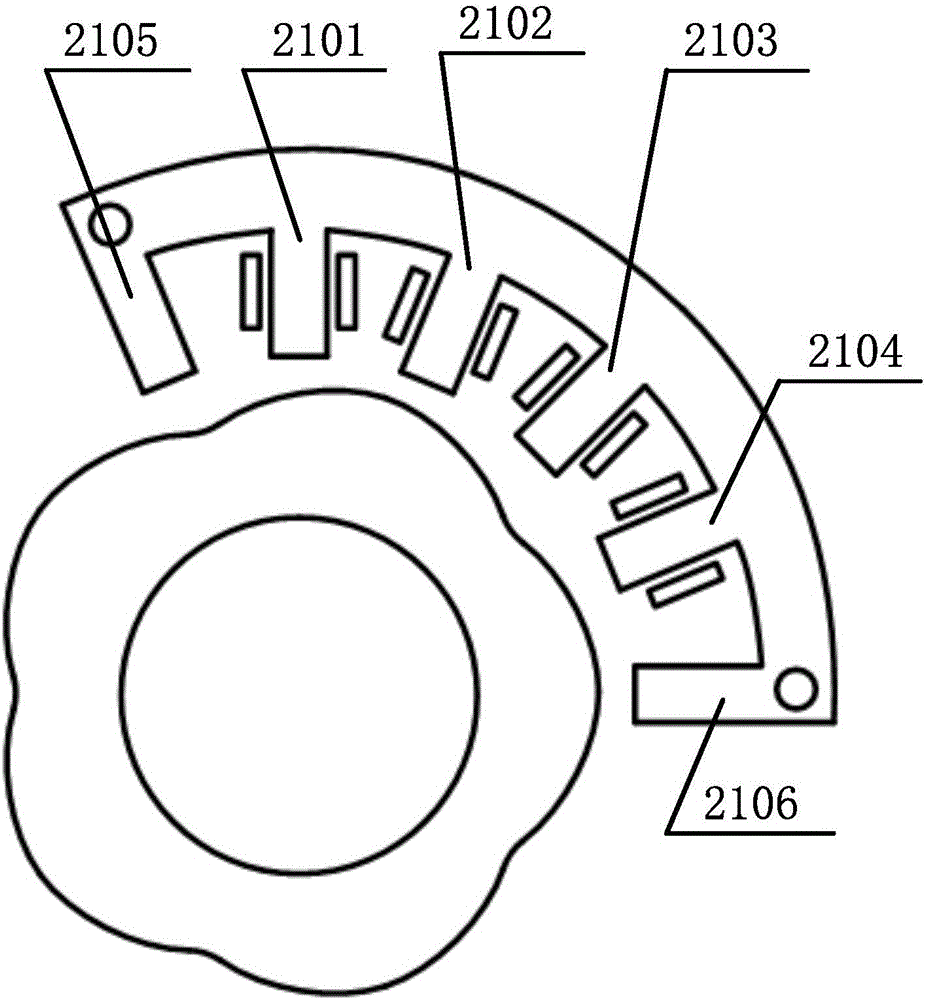

[0070] In this embodiment, K=1 and N=5, so the number of stator detection teeth of the resolver is 4, and the number of salient poles of the rotor is 5. image 3 Shown is a schematic cross-sectional view of the stator and rotor of the resolver. The stator includes a stator yoke and stator detection teeth, the stator detection teeth are arranged on the stator yoke; the angle spanned by the stator yoke is less than 360 degrees, and the rotor includes a rotor core. Both the stator core and the rotor core are formed by stamping silicon steel sheets. In this embodiment, the five salient rotor poles are evenly distributed along the circumference of the rotor core surface. The 4 stator detection teeth are distributed along the circumferential surface of the stator yoke, and the 4 stator detection teeth are distributed clockwise along the circumference as 2101, 2102, 2103, 2104. The included angle between the stator detection teeth 2101 and the stator detection teeth 2102 is 18 degree...

no. 3 example

[0076] In this embodiment, K=1 and N=6, so the number of stator detection teeth of the resolver is 4, and the number of salient poles of the rotor is 6. Figure 4 Shown is a schematic cross-sectional view of the stator and rotor of the resolver. The stator includes a stator yoke and stator detection teeth, the stator detection teeth are arranged on the stator yoke; the angle spanned by the stator yoke is less than 360 degrees, and the rotor includes a rotor core. Both the stator core and the rotor core are formed by stamping silicon steel sheets. In this embodiment, the 6 salient rotor poles are evenly distributed on the circumference of the rotor core surface. The 4 stator detection teeth are distributed along the circumferential surface of the stator yoke, and the 4 stator detection teeth are distributed clockwise along the circumference as 3101, 3102, 3103, 3104. The angle between the stator detection teeth 3101 and the stator detection teeth 3102 is 15 degrees, the angle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com