Switching power source control circuit and switching power source

A technology for controlling circuits and switching power supplies, which is applied in the direction of control/regulation systems, electrical components, and adjustment of electrical variables. It can solve the problems of shortened service life, increased loss, and high heat generation of power devices, so as to reduce losses, save costs, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

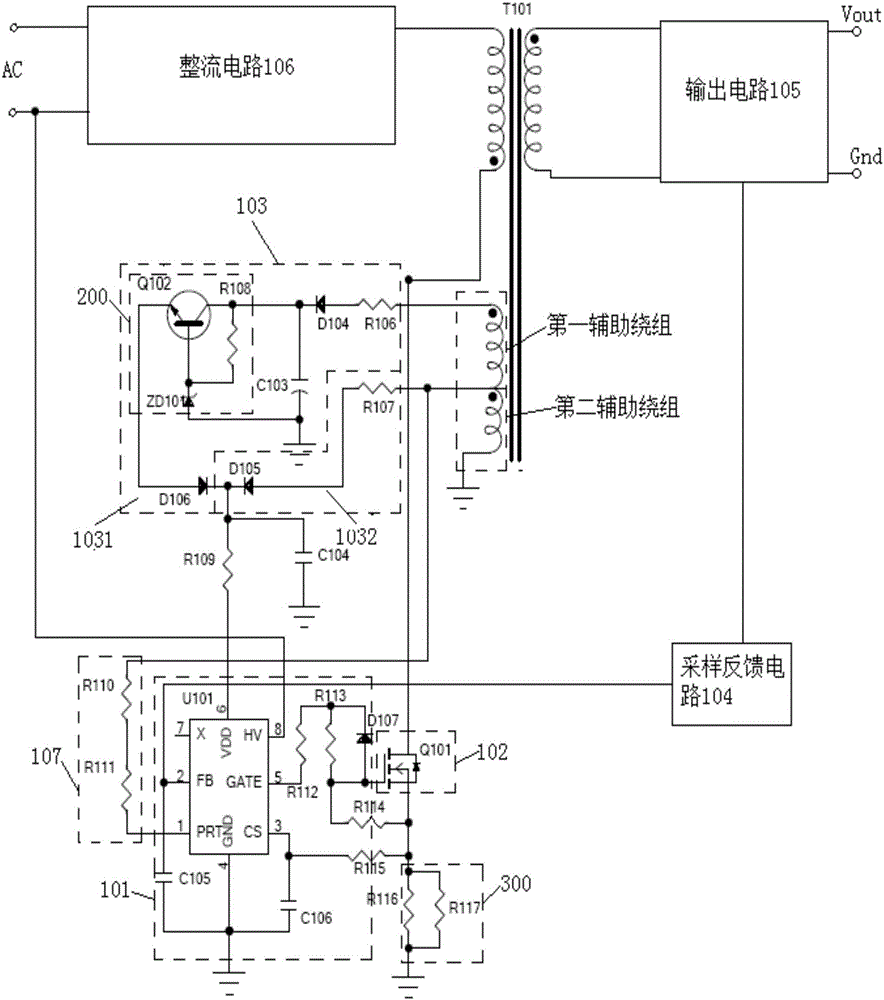

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0033] Aiming at the problems existing in the prior art, the present invention proposes a switching power supply control circuit. The switching power supply control circuit samples the voltage output by the switching power supply and feeds it back to the control circuit to adjust the current of the primary winding of the transformer, thereby regulating the voltage of the transformer. The output voltage of the auxiliary winding is to provide a suitable working voltage for the control circuit, so that the control circuit can work within the normal working range, reduce loss and prolong the service life of the switching power supply.

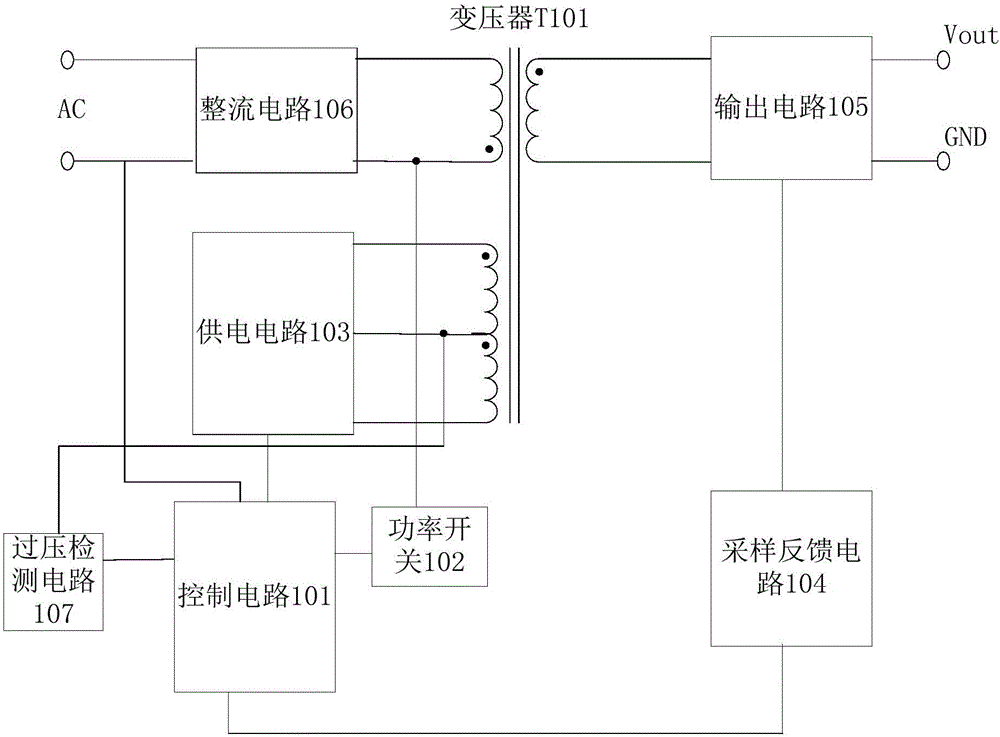

[0034] Such as figure 1 As shown, in the switching power supply control circuit of the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com