Silicone ligands for quantum dots

A technology of quantum dots and ligands, applied in the field of preparing quantum dot binding ligands, which can solve the problems of less attractiveness and low LED efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

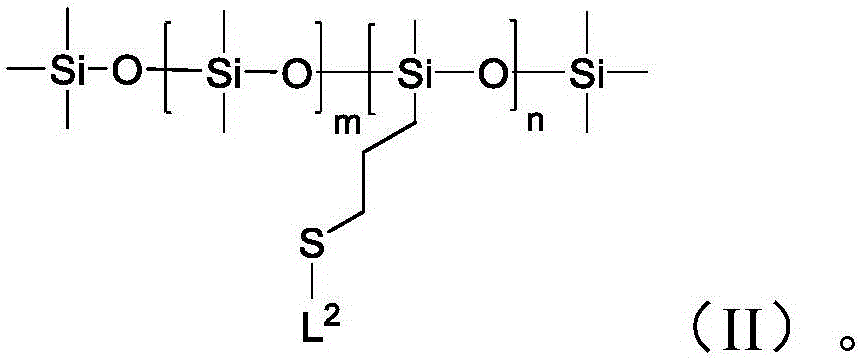

[0298] The method for preparing quantum dot binding ligands of the present invention provides several advantages over existing methods. The method of the present invention provides easier product purification and also allows more control over the molecular weight of the product. By using one or more thiol-ene reactions to synthesize a siloxane backbone and attach additional functional groups, the molecular weight of the product can be easily adjusted to provide high and low molecular weight products.

[0299] IV. Composition

[0300] The quantum dot binding ligand of the present invention can be complexed to a quantum dot (QD). In some embodiments, the invention provides a combination of the quantum dot binding ligand of the invention and the first population of luminescent quantum dots (QDs).

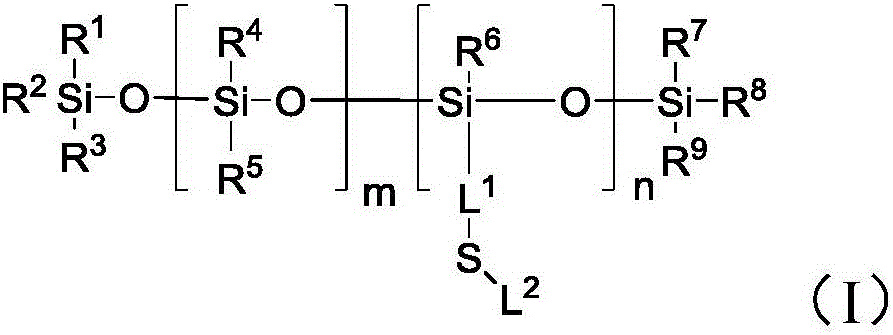

[0301] In some embodiments, the quantum dot binding ligand may have the structure of Formula I as described above.

[0302] V. Quantum dots

[0303] Quantum dots are also called semiconductor...

Embodiment 1

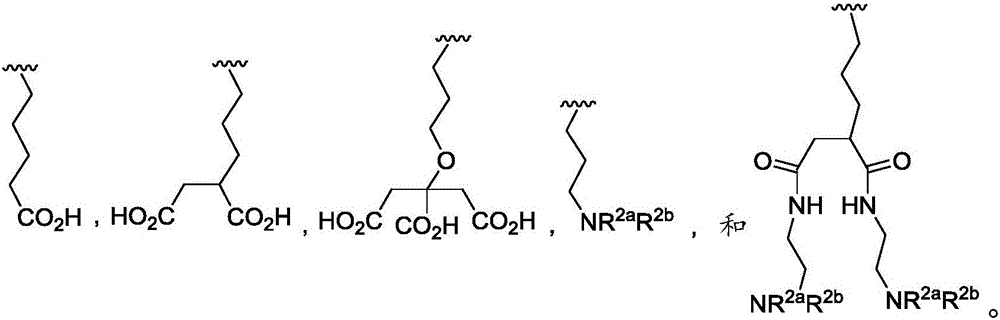

[0333] Preparation of lower MW succinic acid organosilicon ligand

[0334]

[0335] To a 20 mL vial of allyl succinic acid (0.439 g, 2.78 mmol) was added 2 mL of toluene and the mixture was heated to dissolve at 84°C. Add 5.00 g (8.33 mmol SH) of mercapto-functional silicone liquid GP-367 (Genesse Polymers Corporation, Burton MI) into a separate vial, and heat to 84°C. Add the hot silicone solution to the allyl succinic acid solution under rapid stirring, and then immediately add 0.015g pre-dissolved in 0.5mL toluene 88 initiator (DuPont, Wilmington, DE). The reaction continued to be heated at 84°C. After 5 minutes, 0.144 g (1.25 mmol) of allyltrimethylsilane was added. The NMR sample at 20 minutes showed 50% allyl succinic acid remaining. Another 0.43 g (2.99 mmol) of allyltrimethylsilane was added. After 60 minutes, the NMR sample showed 10% allyl succinic acid remaining. After 3 hours, another 0.43 g (2.99 mmol) of allyltrimethylsilane (excess for the remaining SH) was a...

Embodiment 2

[0337] Preparation of higher MW succinic acid organosilicon ligand

[0338]

[0339] The preparation of higher MW succinic acid organosilicon ligand followed the procedure of Example 1, using 0.20 equivalent of allyl succinic acid and 0.47 equivalent of cyclohexane divinyl ether per chain, and then adding an excess of allyl trimethyl Based on silane. The MW of the resulting product was about 8,200.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com