High-resolution scanning microscopy with discrimination between at least two wavelength ranges

A scanning microscopy, high-resolution technology, used in microscopy, material analysis, material analysis by optical means, etc., can solve problems such as cost and expensive flat detectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

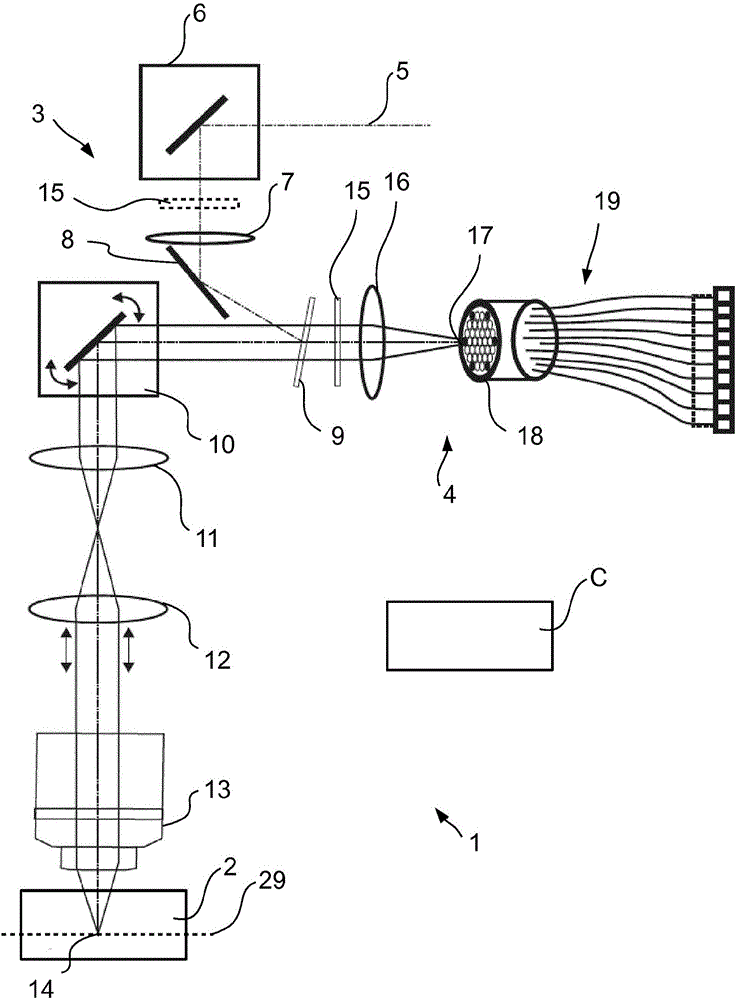

[0038] figure 1 A laser scanning microscope 1 is schematically shown, which is designed for microscopic imaging of a sample 2 . A laser scanning microscope (abbreviated as LSM hereinafter) is controlled by a control device C, and includes an illumination optical path 3 and an imaging optical path 4 . The illumination light path illuminates a point in the test 2, and the imaging light path 4 images the point in a diffraction-limited manner for detection. The illumination optical path 3 and the imaging optical path 4 share an optical device.

[0039] Illumination of the sample 2 takes place in the LSM 1 by means of a provided laser beam 5 which is coupled into a mirror 8 by means of a deflection mirror 6 and a lens 7 which are not further functionally required. The mirror 8 is responsible for transmitting the laser beam 5 at a reflection angle to an incoupling element, for example an emission filter 9 . For an overview of the representation, only the main axis of the laser be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com