A temperature-resistant long-term anti-corrosion coating for ship sewage tank

A long-term anti-corrosion and sewage technology, which is applied in the field of paint manufacturing in the chemical industry, can solve the problems of high construction cost, low paint retention rate, and many times of painting, and achieve the effect of convenient construction and improved water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

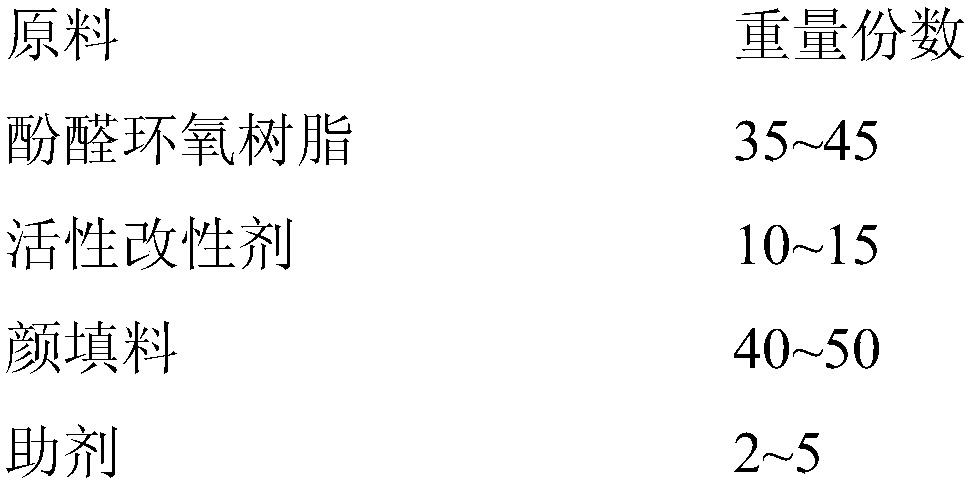

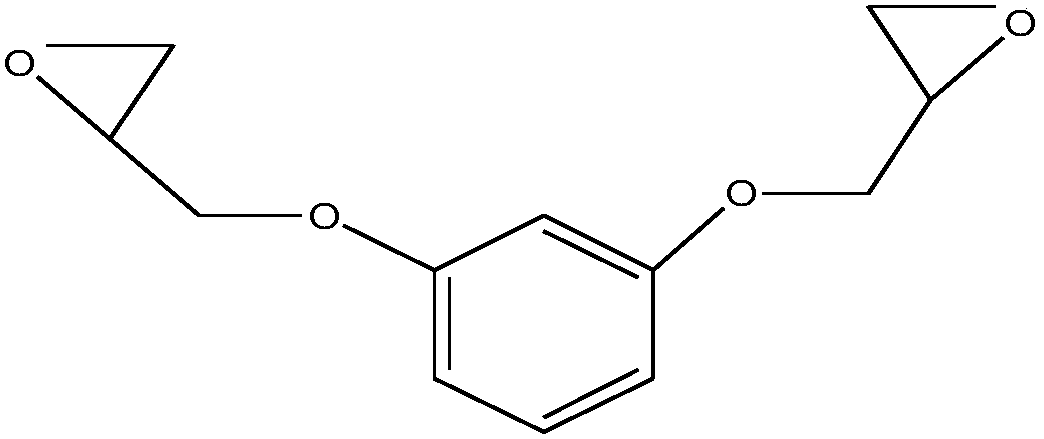

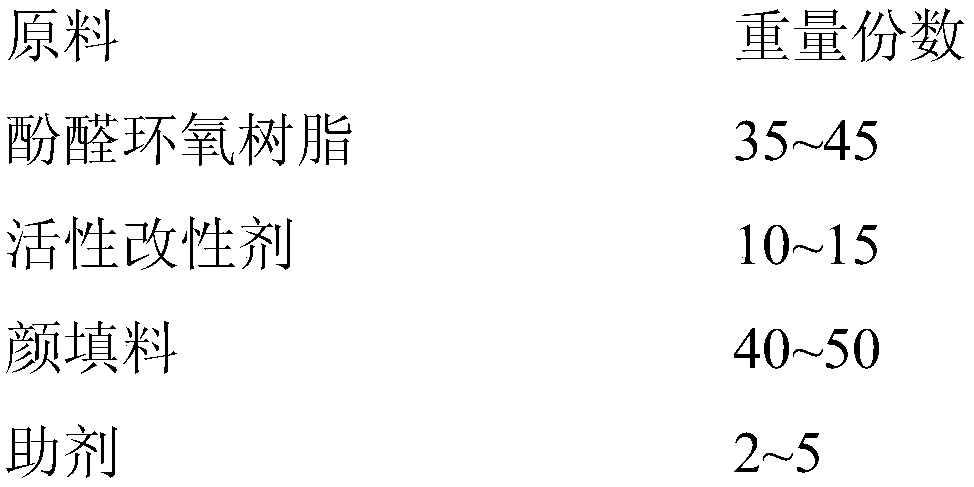

[0029] Put 35 parts by weight of novolac epoxy resin and 15 parts by weight of active modifier RDGE into a stainless steel tank and stir with a high-speed mixer, while stirring, add 2 parts by weight of defoamer (AFCONA2723, 2020), wetting and dispersing agent (BYK-2151 ) 1.5 parts by weight, leveling agent (AFCONA3700) 1.5 parts by weight, after stirring evenly with the resin, add 10 parts by weight of titanium dioxide, iron phosphorus powder 10, zinc phosphate 8, aluminum tripolyphosphate 12 parts by weight, further stir evenly, and then use Grind with a sand mill or a three-roll mill to a standard fineness of less than 60um, filter and fill into a barrel to become component A of the coating.

[0030] The modified alicyclic amine adopts American company Amicure PACM, 21 parts by weight, and the phenalkamine adopts Cardolite 3060, 7 parts by weight, and is configured as 28 parts by weight of a composite modified amine curing agent, which is put into a stainless steel tank and ...

Embodiment 2

[0034] Put 45 parts by weight of novolac epoxy resin and 10 parts by weight of active modifier RDGE into a stainless steel tank and stir with a high-speed mixer, add 1.2 parts by weight of defoamer (Deqian 6800), 0.8 parts by weight of wetting and dispersing agent (Afcona5065) 1.0 parts by weight of leveling agent (AFCONA3700), stir evenly with resin and add 8 parts by weight of titanium dioxide, 12 parts by weight of talcum powder, 14 parts by weight of aluminum tripolyphosphate, 7.7 parts by weight of zinc phosphate, 0.3 parts by weight of graphene, Stir evenly, and then use a sand mill or a three-roll mill to grind to a standard fineness of less than 60um, filter and pack into paint A component.

[0035]The modified alicyclic amine adopts Amicure PACM from American company, 24 parts by weight, and the phenalkamine uses 8 parts by weight of Cardolite 3060, and configures 32 parts by weight of composite modified amine curing agent, and the curing accelerator DMP-302 parts by w...

Embodiment 3

[0038] It is used in the sewage tank of a cargo ship in Ningbo Shipyard, Zhejiang. The sewage in the cabin is a mixture of diesel oil, engine oil and domestic sewage. The original protective coating rusted after 3 months of use. Using the coating prepared in Example 2, grind the surface of the sewage tank to St2 level during construction, mix the A and B components according to the weight ratio of A:B=3:1, stir evenly, and spray with high-pressure airless equipment 2 coats, the first spraying in the morning and the second spraying after the surface is dry in the afternoon, the spraying construction is completed in one day, and the coating is cured at room temperature (25°C) for seven days before use. The obtained coating is smooth and bright. After being soaked in sewage and used for 6 months, it is found that the coating is intact and there is no rust phenomenon, which meets the needs of users.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap