Method for extracting vegetable oil under subcritical low temperature

A subcritical and vegetable oil technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of high energy consumption of equipment, destruction of biologically active components, low oil yield, etc., to improve the quality of oil products , reduce energy consumption, improve the effect of oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

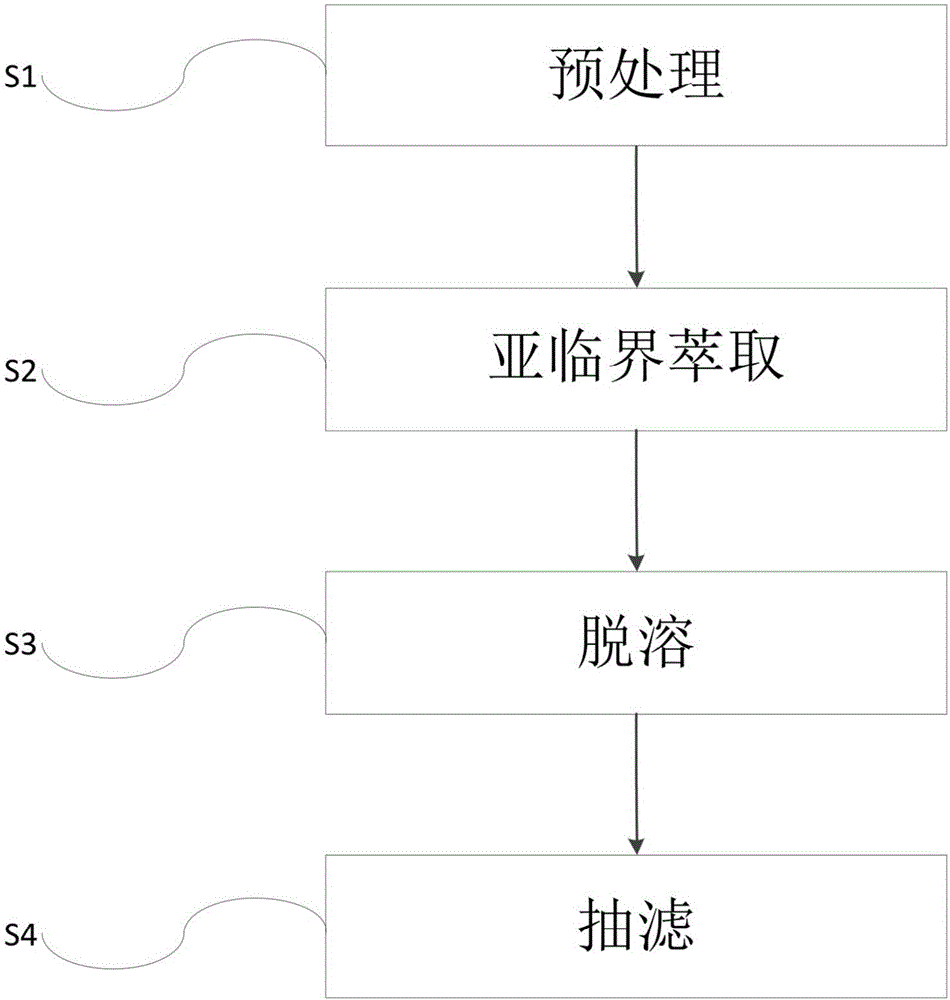

Image

Examples

Embodiment 1

[0023] Embodiment 1: the extraction of tomato seed oil

[0024] S1: Pretreatment: select tomato seeds as raw materials, place them in a low-temperature ventilated place and dry them at 40°C for 48 hours until the moisture content is 4%, then put the dried tomato seeds into a grinder for crushing, and the particles are not higher than 40 mesh;

[0025] S2: Subcritical extraction: Put 400g tomato seed particles into the subcritical extraction kettle, control the vacuum pump to make the vacuum degree in the subcritical extraction kettle and the separation kettle be -0.04Mpa; inject the extraction solvent butane into the subcritical extraction kettle to Submerge the sample completely, turn on the hot water heating valve to heat, control the temperature and extraction pressure in the extraction kettle, the temperature is 35°C, the pressure is 0.05Mpa, repeat the extraction four times, the first extraction time is 60min, and the second extraction time is 40min , the third extraction...

Embodiment 2

[0028] Embodiment 2: the extraction of pumpkin seed oil

[0029] S1: Pretreatment: select pumpkin seeds as raw materials, place them in a low-temperature and ventilated place and dry them at 40°C for 48 hours until the moisture content is 4%, then put the dried pumpkin seeds into a grinder for crushing, and the particles are not higher than 40 mesh;

[0030] S2: Subcritical extraction: Put 400g of pumpkin seed particles into the subcritical extraction kettle, control the vacuum pump to make the vacuum degree in the subcritical extraction kettle and the separation kettle be -0.04Mpa; inject the extraction solvent butane into the subcritical extraction kettle to Submerge the sample completely, turn on the hot water heating valve to heat, control the temperature and extraction pressure in the extraction kettle, the temperature is 35°C, the pressure is 0.05Mpa, repeat the extraction four times, the first extraction time is 60min, and the second extraction time is 40min , the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com