High-temperature-resistant high-elastic nickel-chromium alloy strip and preparation method thereof

A nickel-chromium alloy and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant and high-elastic nickel-chromium alloy strips and their preparation fields, can solve the problems of poor temperature resistance and cannot guarantee reliable sealing, etc., and achieves broad industrial application prospects, simple preparation process, and improved The effect of strip organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

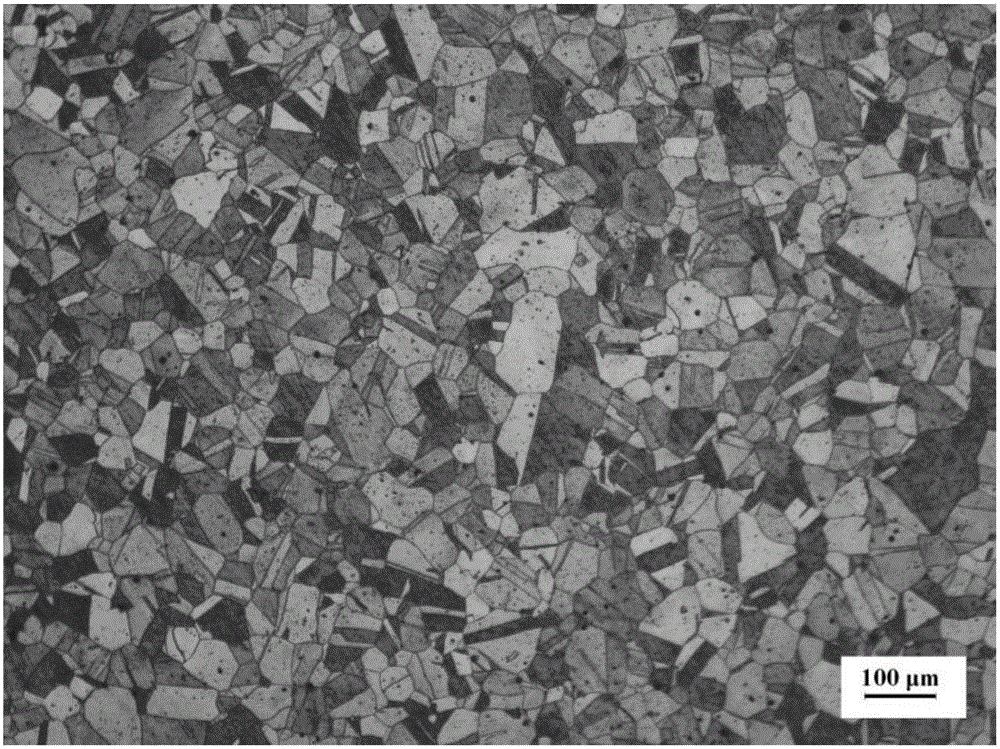

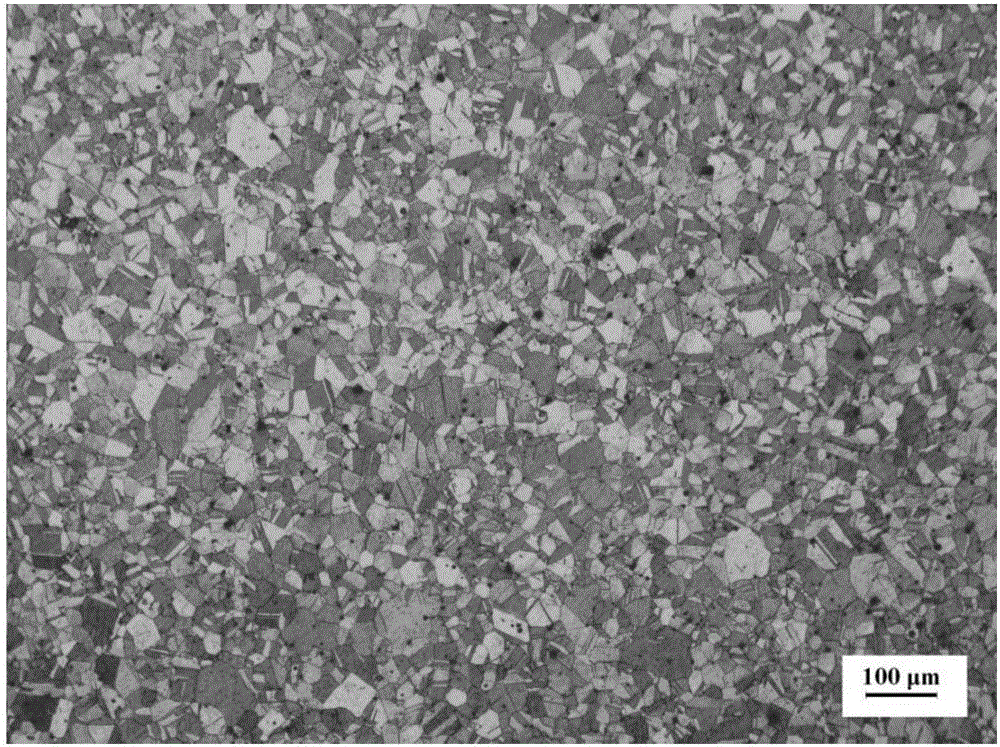

Image

Examples

Embodiment 1

[0024] The production process of high-temperature-resistant and high-elastic nickel-chromium alloy strip is: batching→vacuum induction melting→vacuum self-consumption smelting→homogenization→billet opening→hot forging→hot rolling→solution treatment→pickling→cold rolling→annealing of finished products→ Package.

[0025] In the batching process, the weight ratio of each component of the high-temperature resistant and high-elastic nickel-chromium alloy strip is: C: 0.03%, B: 0.005%, Al: 1.5%, Ti: 2.0%, Cr: 19.5%, Mo: 8.5% , Co: 10.0%, and the rest is Ni.

[0026] In the homogenization process, a two-stage soaking method was adopted. After holding at 850°C for 3 hours, the temperature was raised to 1180°C at a rate of 55°C / h and held at 30 hours.

[0027] In the hot forging process, the starting forging temperature is 1150°C, and the final forging temperature is 1030°C.

[0028] In the hot rolling process, the heating temperature was 1160° C., the finish rolling temperature was ...

Embodiment 2

[0036] The production process of high-temperature-resistant and high-elastic nickel-chromium alloy strip is: batching→vacuum induction melting→vacuum self-consumption smelting→homogenization→billet opening→hot forging→hot rolling→solution treatment→pickling→cold rolling→annealing of finished products→ Package.

[0037] In the batching process, the weight ratio of each component of the high-temperature resistant and high-elastic nickel-chromium alloy strip is: C: 0.03%, B: 0.006%, Al: 1.6%, Ti: 2.1%, Cr: 20.5%, Mo: 8.8% , Co: 10.5%, and the rest is Ni.

[0038] In the homogenization process, a two-stage soaking method was adopted. After holding at 860°C for 3 hours, the temperature was raised to 1200°C at a rate of 50°C / h and held for 30 hours.

[0039] In the hot forging process, the starting forging temperature is 1150°C, and the final forging temperature is 1030°C.

[0040] In the hot rolling process, the heating temperature was 1165° C., the finish rolling temperature was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com