Mesh-packing yarn manufacturing device and mesh-packing yarn manufacturing method

The technology of a production device and a yarn feeding device is applied in the field of yarn production devices, which can solve the problems of limiting the length of spinnable fibers, unable to spin chemical fibers and wool, etc., and achieves the effects of simple and reliable structure, low production cost and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

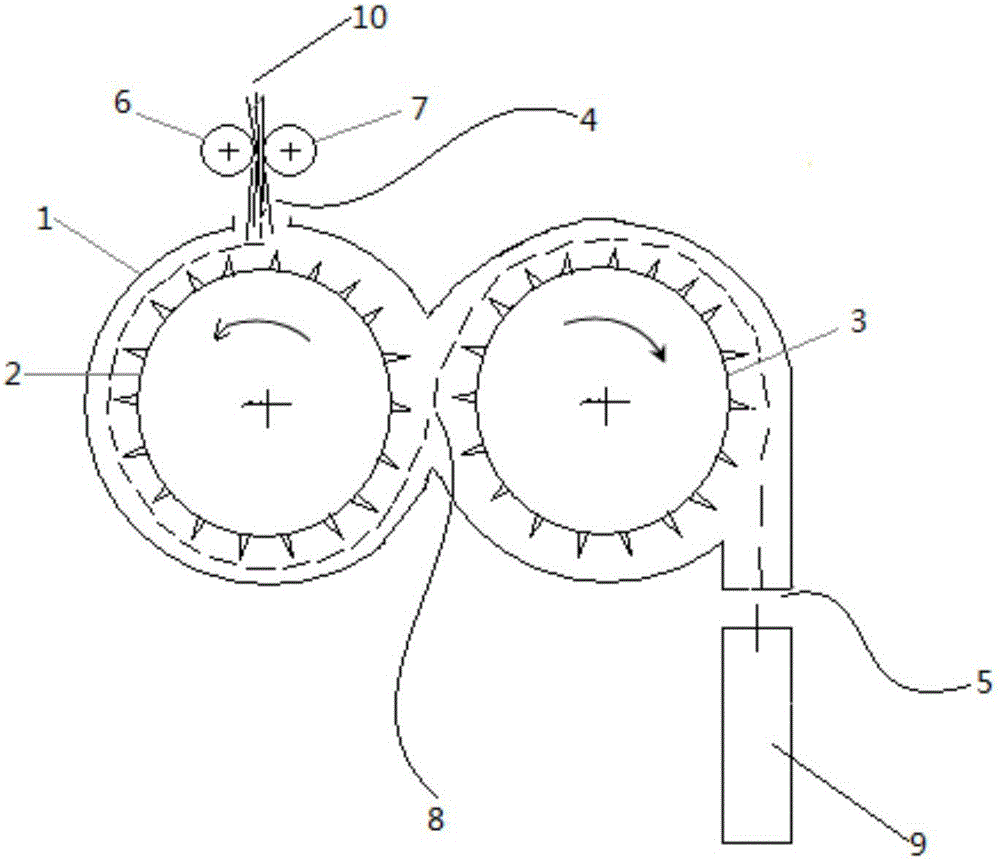

[0019] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0020] like figure 1 Shown, a kind of making device of net wrapped yarn, comprises: licker-in 2 and licker-in 3, licker-in 2 and licker-in 3 are arranged at intervals on the same vertical plane, it is characterized in that licker-in 2 and licker-in 3 are all set In a protective case 1, a yarn feeding device is provided at the entrance 4 of one end of the protective case 1, and a weaving device 9 is provided at the exit 5 of the other end, and the fiber sliver 10 can be fed into the protective case 1 from the yarn feeding device, and bypassed in turn. The licker-in roller 2 and the licker-in roller 3 finally pass through the outlet 5 and enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com