Basement exterior wall single-side formwork supporting system and method

A technology of basement exterior wall and support system, which is applied to the connection parts of formwork/formwork/work frame, the preparation of building components on site, and construction, etc. and other problems, to achieve the effect of easy quality control, convenient material acquisition and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

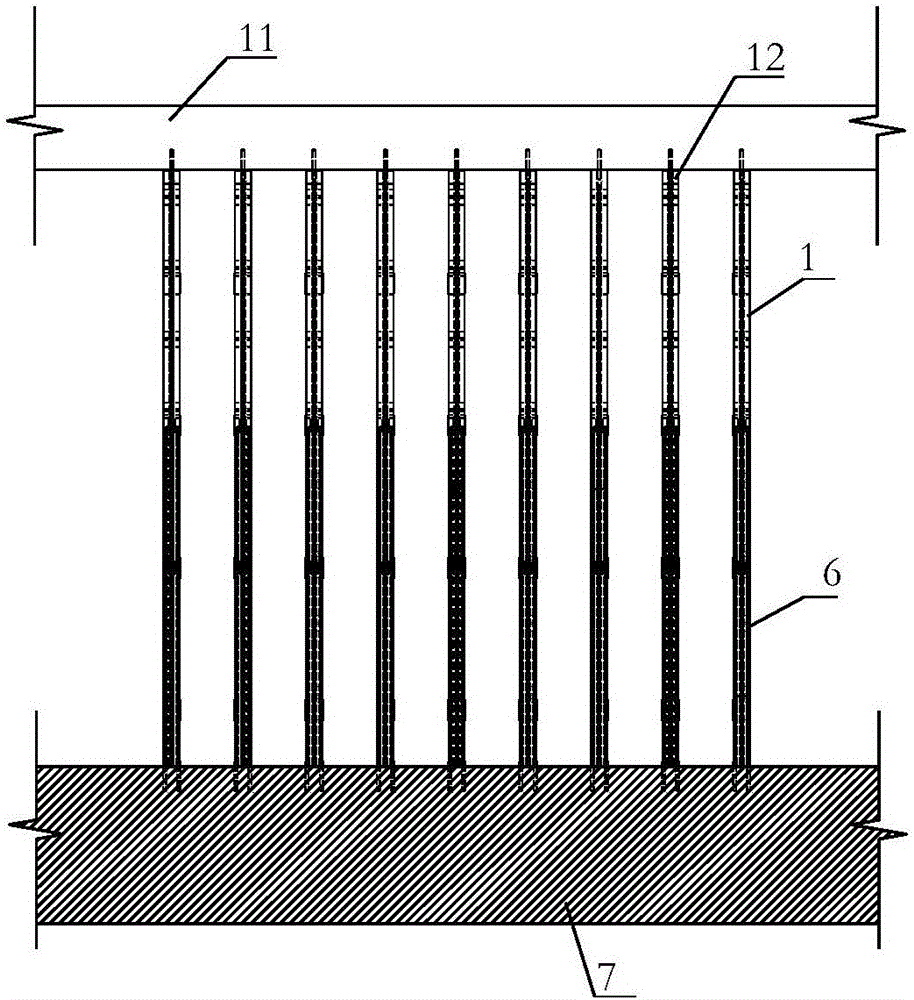

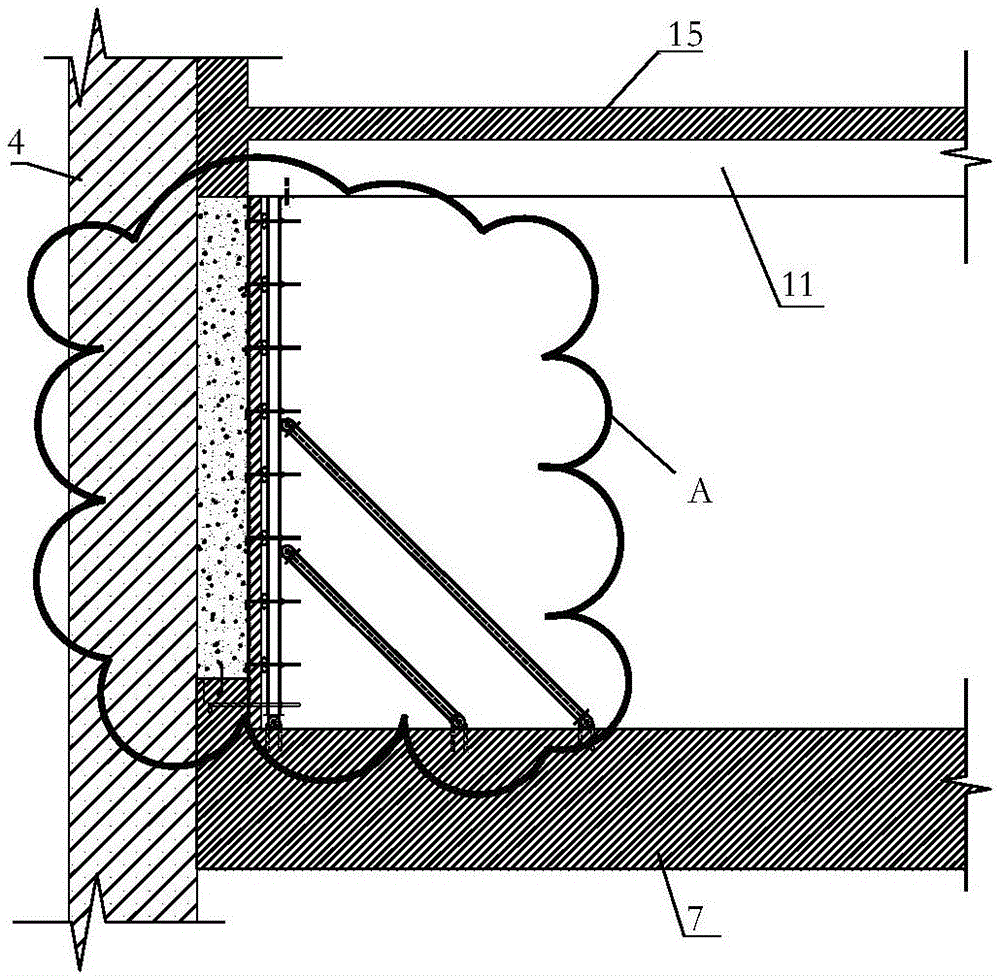

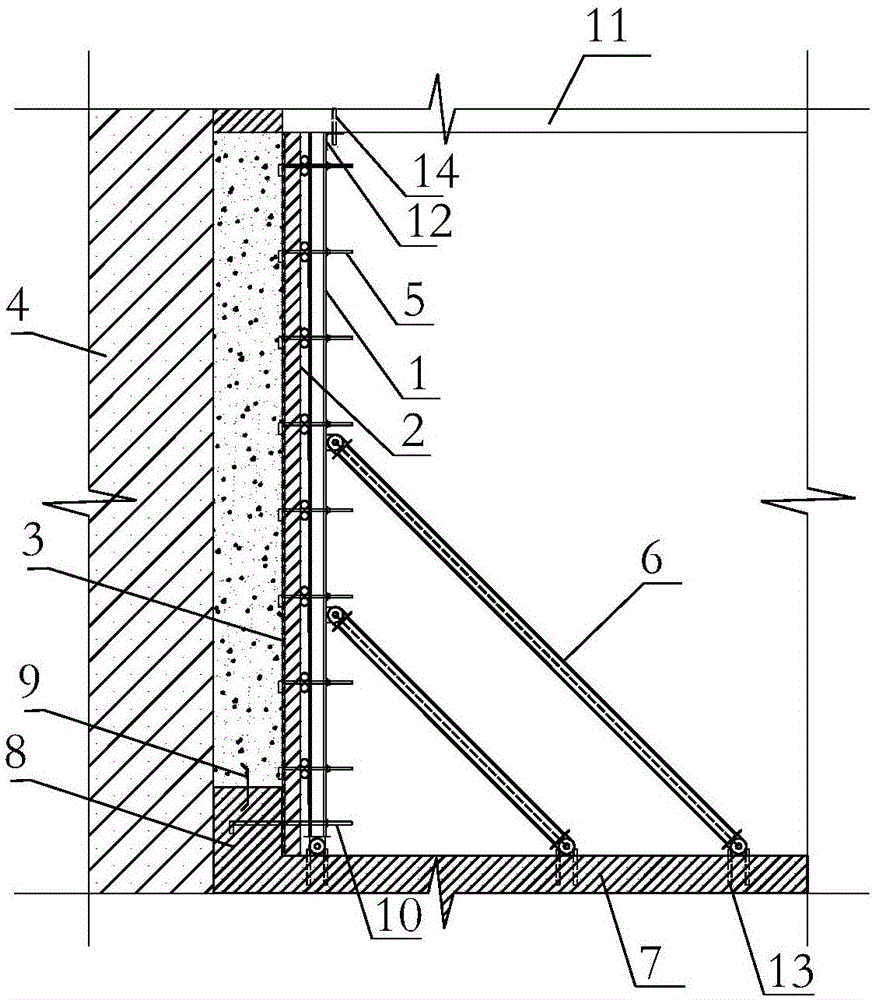

[0029] refer to Figure 1 to Figure 3 The structural composition of the one-side formwork support system for the basement exterior wall of the present invention is described in detail.

[0030] The single-sided formwork support system of the basement exterior wall is provided with reinforcing rods 1, wooden squares 2, formwork 3 and enclosure piles 4 along the basement exterior walls from inside to outside. The pull bolts 5 are fixedly connected, and the reinforcing rod 1 is provided with a diagonal brace 6 on the side far away from the wooden side 2, and one end of the diagonal brace 6 is fixedly connected with the reinforcing rod 1, and the other end of the diagonal brace 6 is fixedly connected with the basement base plate 7.

[0031] Specifically, the enclosure pile 4 is used as the outer formwork of the basement exterior wall, and the inner formwork of the basement exterior wall is erected on the foundation floor 7, that is, the single-side formwork support system of the b...

Embodiment 2

[0038] Please continue to refer Figure 1 to Figure 3 , the present invention also discloses a method for supporting formwork of a single-side formwork support system for a basement exterior wall, the method for supporting formwork includes the following steps:

[0039] 1. A vertical waterproof steel plate 9 is provided at the joint 8 between the basement exterior wall and the foundation floor 7;

[0040] 2. The reinforcement bar 1, the wooden square 2, and the formwork 3 are fastened together through the pull bolts 5 in order to form a formwork support system, so that the lower end of the formwork support system is fixedly connected with the embedded steel plate 13 in the foundation bottom plate 7, so that the formwork support system The upper end is fixedly connected to the concrete beam 11 through the angle steel 12 and the anchor bar 14, and the basement floor 15 is above the concrete beam 11;

[0041] 3. Fixedly install the diagonal brace 6 at the center of gravity and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com