Continuous slag discharging device of biomass particle combustion furnace

A biomass particle and combustion furnace technology is applied in the field of slagging of combustion furnaces, which can solve problems such as damage to safe and efficient operation, inability to continuously discharge slag, and easy blockage, and achieve the effects of simple structure, reasonable design, and safe and efficient combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

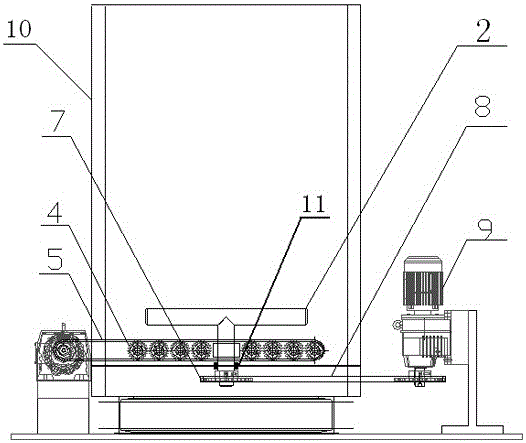

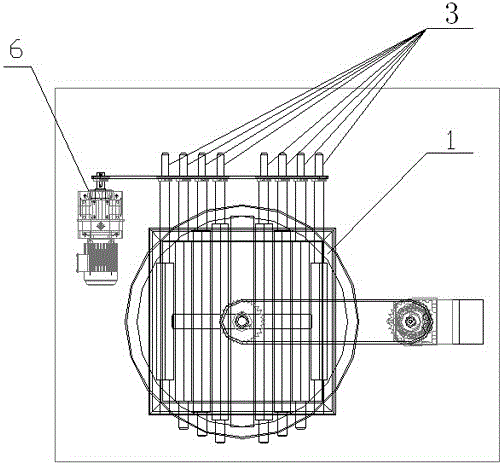

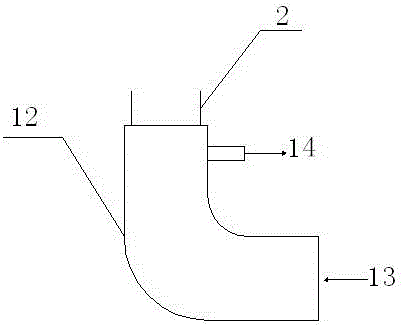

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Depend on Figure 1-4 It can be seen that a continuous slagging device for a biomass pellet combustion furnace includes a rotating grate 1 and a rotating slag breaking rod 2. The bottom of the furnace wall of the furnace 10; the rotating slag rod 2 is fixed by two high-temperature-resistant bearings 11 installed on the upper and lower sides of the furnace bottom steel plate of the combustion furnace 10; the rotating grate 1 is driven by the first driving mechanism, and the The rotating slag rod 2 is driven by the drive mechanism two. The rotating grate 1 is composed of a certain number of cast iron grate bars 3, each cast iron grate bar 3 is independent, fixed on the furnace wall bottom of the combustion furnace 10 through a graphite bearing, each cast iron grate bar 3 One end installs a chain gear-4, and chain gear-4 links to each other with drive mechanism-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com