Ture triaxial rock test machine with temperature control system and temperature control method thereof

A technology of rock testing machine and temperature control system, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of error, cost, increase equipment manufacturing cost, oil loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0124] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

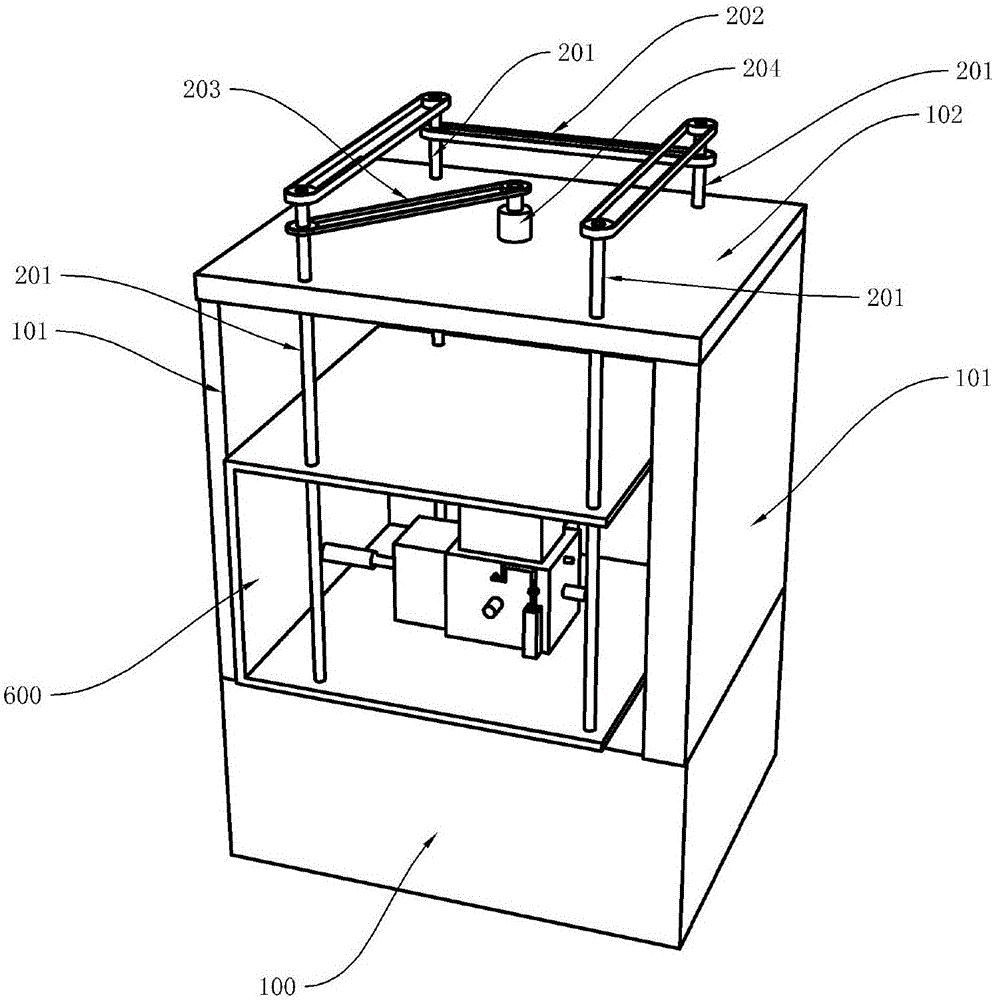

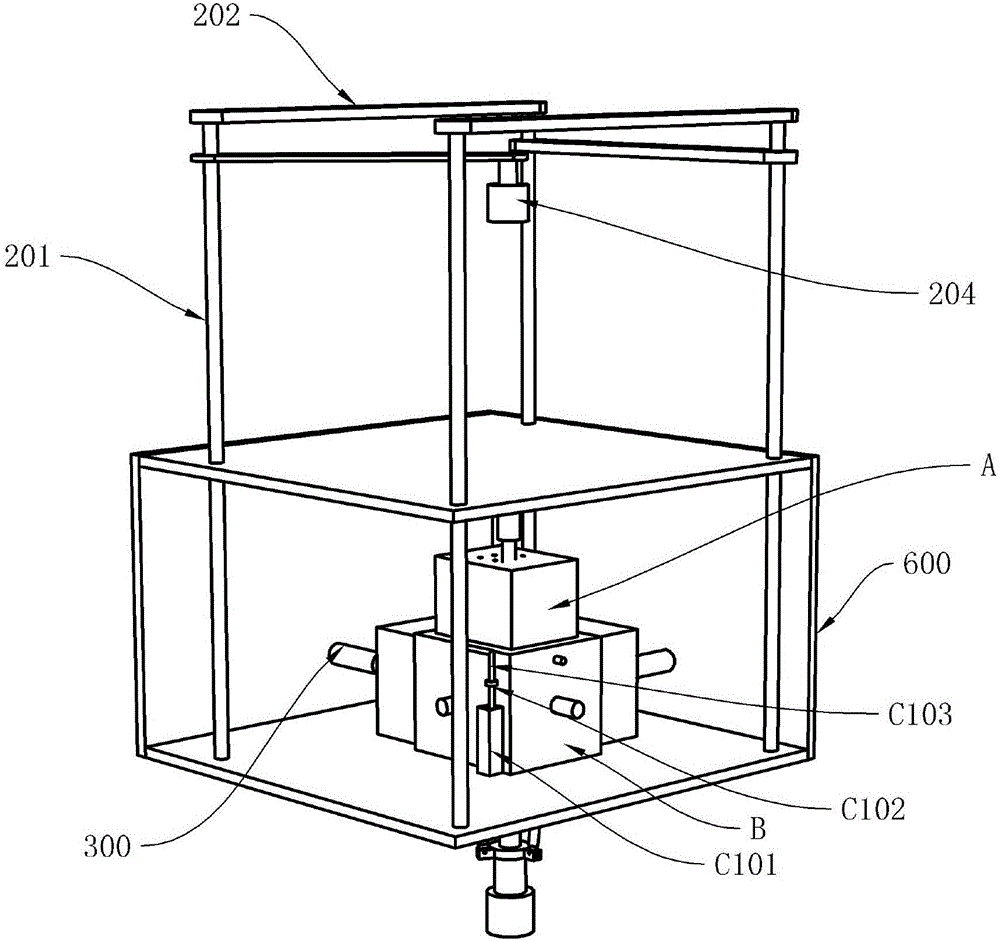

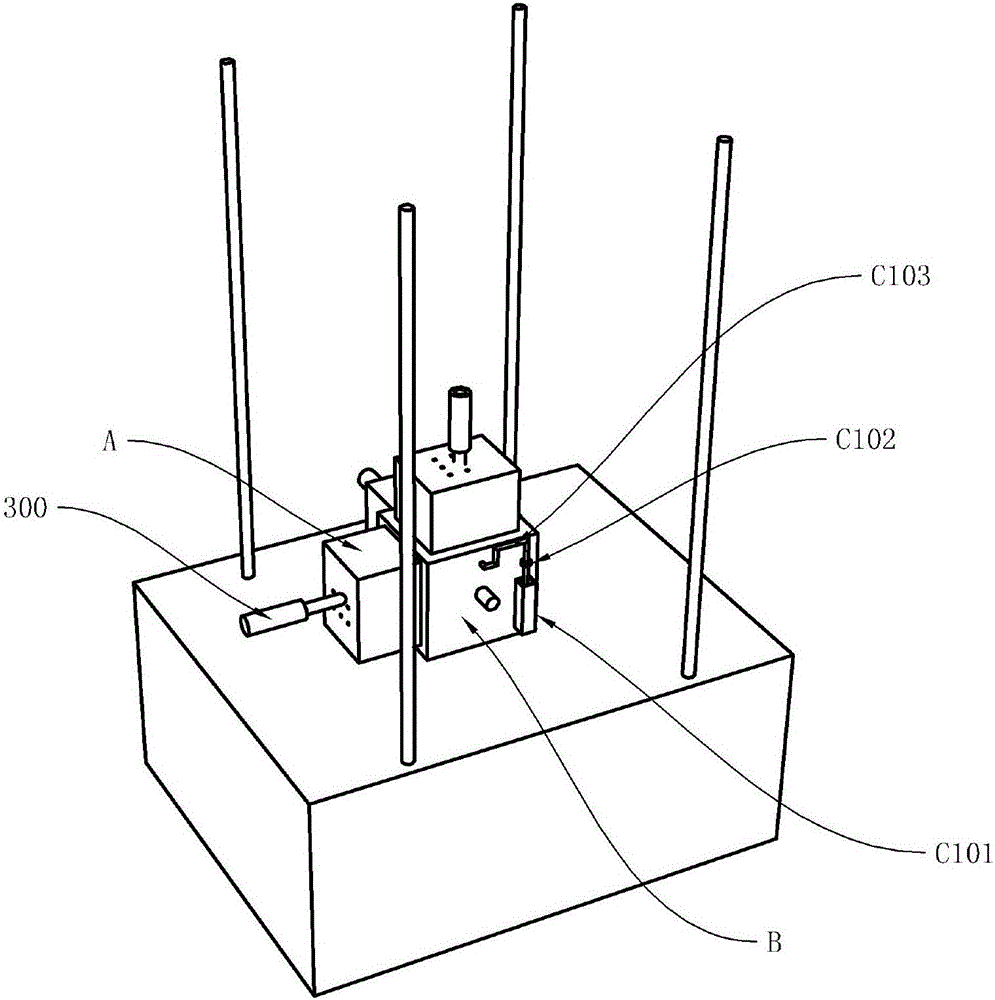

[0125] see Figure 1 to Figure 6 , a true triaxial rock testing machine with a temperature control system, including a frame base 100, the top surface of the frame base 100 is connected and fixed with the bottom surface of two parallel side support plates 101, and the side support plates A frame top plate 102 is fixed on the top surface of the 101;

[0126] The tops of four screw rods 201 pass through the top plate 102 of the frame, the lifting frame 600 and the frame base 100 are rotatably assembled; the screw rods 201 are threaded and assembled with the lifting frame 600;

[0127] The top of the screw rod 201 protrudes from the top plate 102 of the frame, and screw pulleys are fixed on the extending ends. The four screw rods 201 are connected to the top screw pulleys through the first lifting synchronous belt 202 to form a belt transmission structure. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com