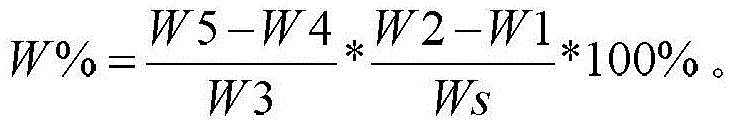

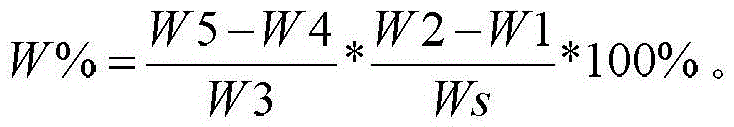

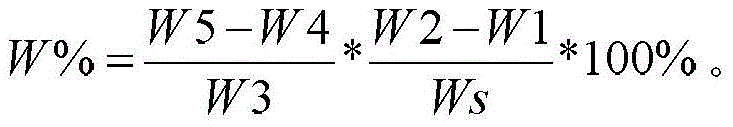

Method for determining iron soap content in emulsion

A measurement method and emulsion technology, applied in the direction of weighing by removing certain components, can solve problems such as iron soap is not easy to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0050] The first embodiment: the normal phase solid phase extraction column used in this embodiment is: HF Mega BE-Si, 5 gm, 20 ml (Agilent, Part No: 14256026).

[0051] Sample dehydration step: Accurately weigh 200.00g of the emulsion sample, heat it for 2 hours with a rotary evaporator at a vacuum degree greater than or equal to 0.09Mpa, and a water bath of 60°C to obtain a dehydrated sample, and collect it in a 50ml small beaker.

[0052] Purification step: place the 50ml small beaker on the magnetite for 30min.

[0053] Iron soap enrichment step, sample the test sample of 1.0000g gram from the top of the dehydrated sample, dissolve it with 10ml chloroform to obtain the chloroform aqueous solution of the test sample, add the normal phase solid phase extraction column activated with 20ml chloroform in advance, Control the chloroform aqueous solution of the test sample to pass through the normal phase solid phase extraction column at a speed of 1ml / min, and wash the normal ph...

no. 2 example

[0057] The second embodiment: the normal phase solid phase extraction column used in this embodiment is: HF Mega BE-Si, 5 gm, 20 ml (Agilent, Part No: 14256026).

[0058] Sample dehydration step: Accurately weigh 400.00g of the emulsion sample, heat it for 2 hours with a rotary evaporator at a vacuum degree greater than or equal to 0.09Mpa, and a water bath at 70°C to obtain a dehydrated sample, and collect it in a 50ml small beaker.

[0059] Purification step: place the 50ml small beaker on the magnetite for 30min.

[0060] Iron soap enrichment step, sample the test sample of 5.0000g gram from the top of the dehydrated sample, dissolve it with 20ml chloroform to obtain the chloroform aqueous solution of the test sample, add the normal phase solid phase extraction column activated with 60ml chloroform in advance, Control the chloroform aqueous solution of the test sample to pass through the normal phase solid phase extraction column at a speed of 1ml / min, and wash the normal p...

no. 3 example

[0064] The third embodiment: the normal phase solid phase extraction column used in this embodiment is: CNWBOND SI SPE2G, 10ML (Anpel, Part No: SBEQ-CA1358)

[0065] Sample dehydration step: Accurately weigh 100.00g of the emulsion sample, heat it for 1 hour with a rotary evaporator at a vacuum degree greater than or equal to 0.09Mpa, and a water bath of 60°C to obtain a dehydrated sample, and collect it in a 50ml small beaker.

[0066] Purification step: place the 50ml small beaker on the magnetite for 30min.

[0067] Iron soap enrichment step, sample 0,5000g of test sample from the top of the dehydrated sample, dissolve it with 10ml of chloroform to get the chloroform aqueous solution of the test sample, add it to the normal phase solid phase extraction column activated in advance with 10ml of chloroform , the chloroform aqueous solution of the test sample is controlled to pass through the normal phase solid phase extraction column at a speed of 1ml / min, and the normal phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com