Simple chip device convenient to disassemble and assemble and used for joint inspection of typical tumor markers

A tumor marker, a typical technology, applied in the field of analysis and testing, can solve the problems of fine liquid flow, which have not been properly solved, and large flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

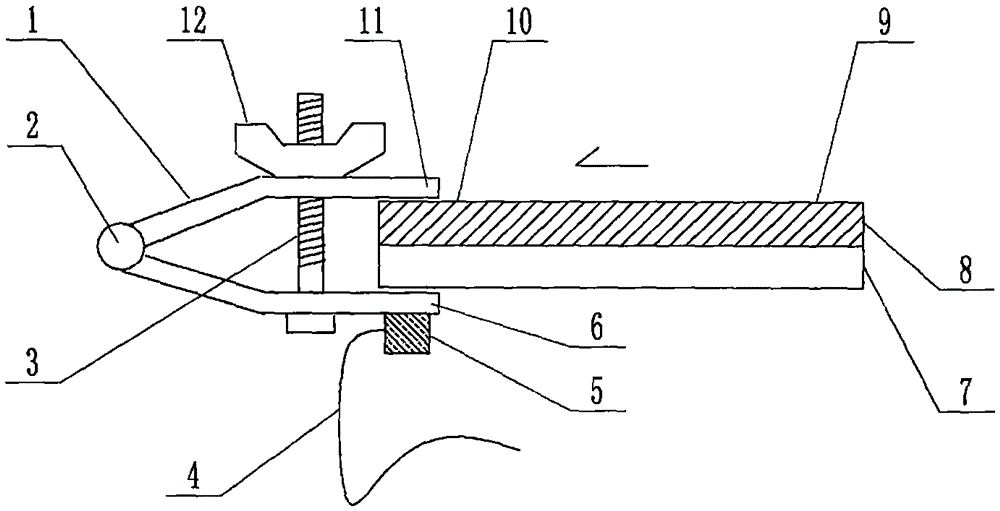

[0055] exist figure 1 In the example shown in this case, the main point of this example is that the structure of the device includes a multi-channel microfluidic chip, and the structure of the microfluidic chip includes a substrate 8 and a cover sheet 7 that are attached to each other. , the substrate 8 and the cover sheet 7 are both plates or sheets, and the side of the substrate 8 facing the cover sheet 7 contains a channel structure formed by a molding process or an etching process. 8 also contains a window structure connected to the channel structure and pierced through the substrate 8 through a molding process, an etching process or a simple punching process. A microfluidic chip containing a pipeline structure and a liquid pool structure connected to it is constructed. The structure of the pipeline is located in the interface area where the substrate 8 and the cover sheet 7 are attached to each other. One side of the window is covered by the cover The sheet 7 is blocked ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com