High-luminance diffusion silver-plated reflective film and preparation method thereof

A reflective film and diffusion-type technology, applied in the field of high-brightness diffused silver-plated reflective film and its preparation, can solve the problems of insufficient brightness of reflective film, LED lamp shadows, reducing diffusion film, etc., so as to reduce the number of diaphragms used and reduce the cost. , good diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

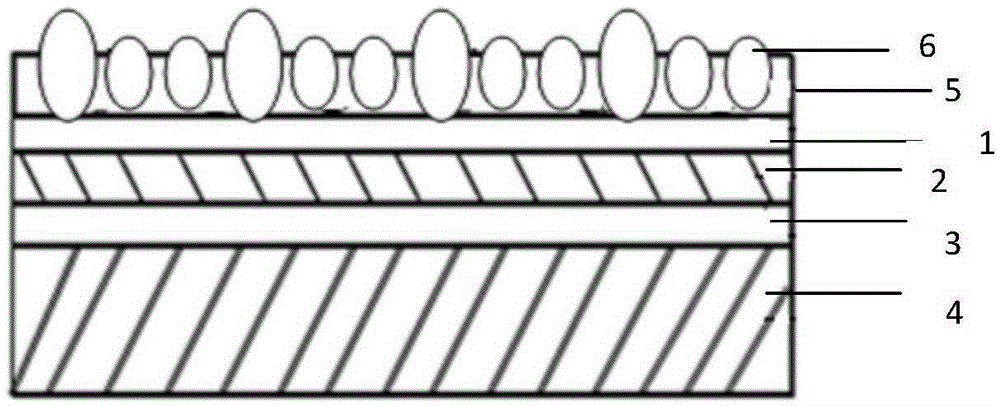

[0051] The high-brightness diffused silver-plated reflective film provided by the present invention includes, from bottom to top, a base layer, a silver-plated layer, an acrylate polymer layer, a protective layer and a diffusion coating; the diffusion coating includes adhesive agent and diffusing particles, the diffusing particles are composed of large-diameter diffusing particles and small-diameter diffusing particles, and the diffusing particles are bonded on the surface of the protective layer by an adhesive.

[0052] The base layer is a white opaque PET polyester layer, and the protective layer is a transparent PET polyester layer.

[0053] The upper surface of the protective layer is coated with the diffusion coating, the lower surface of the protective layer is coated with the acrylate polymer layer, and the lower surface of the acrylate polymer layer is coated with a layer of silver metal, silver metal A silver-plated layer is formed, and the lower surface of the silver...

Embodiment 2

[0064] The high-brightness diffused silver-plated reflective film provided in Example 1, wherein,

[0065] The thickness of the base layer was 96.5 μm.

[0066] The thickness of the silver-plated layer is 0.5 μm.

[0067] The thickness of the acrylate polymer layer was 5 μm.

[0068] The thickness of the diffusion coating was 36 μm.

[0069] The thickness of the protective layer is 50 μm.

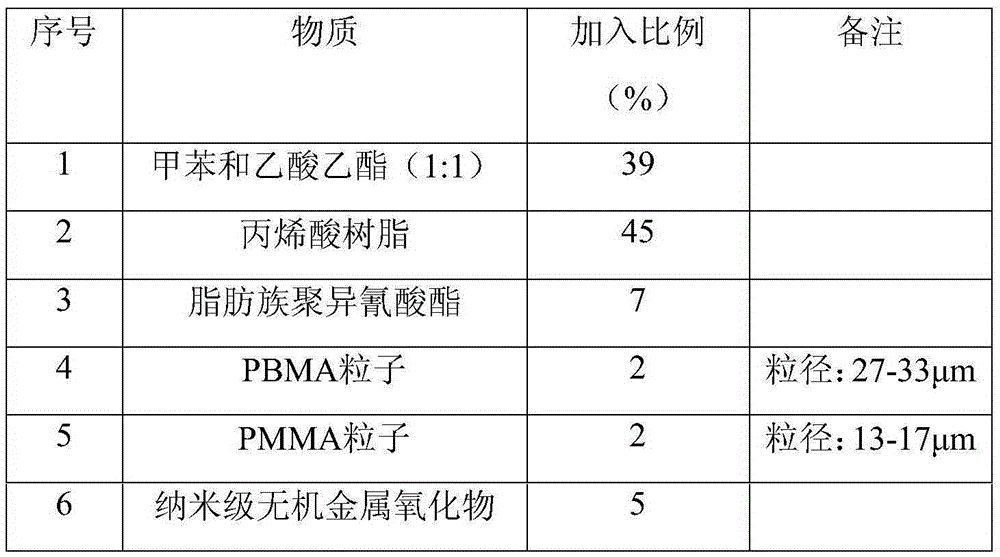

[0070] In the preparation process, the raw materials of the diffusion coating were first prepared into a diffusion coating coating solution, 39 parts by weight of a mixed solvent of toluene and ethyl acetate (weight ratio of 1:1), 45 parts by weight of acrylic resin , 7 parts by weight of aliphatic polyisocyanate crosslinking agent, 2 parts by weight of large-diameter diffusion particles, 2 parts by weight of small-diameter diffusion particles, and 5 parts by weight of nanoscale inorganic metal oxide antistatic agent are uniformly mixed and stirred to obtain diffusion Coating coating li...

Embodiment 3

[0075] The high-brightness diffused silver-plated reflective film provided in Example 1, wherein,

[0076] The thickness of the base layer was 123 μm.

[0077] The thickness of the silver-plated layer is 1 μm.

[0078] The thickness of the acrylate polymer layer was 4 μm.

[0079] The thickness of the diffusion coating was 30 μm.

[0080] The thickness of the protective layer is 30 μm

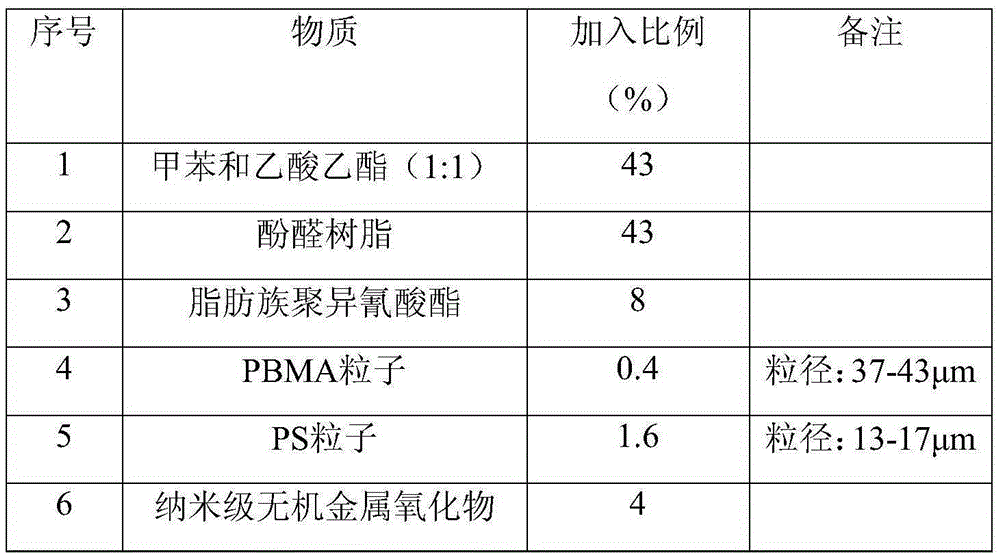

[0081] In the preparation process, the raw materials of the diffusion coating were first prepared into a diffusion coating coating solution, a mixed solvent of 41 parts by weight of toluene and methyl ethyl ketone (weight ratio of 1:1), and 45 parts by weight of epoxy resin, 7 parts by weight of aliphatic polyisocyanate crosslinking agent, 0.75 parts by weight of large-diameter diffusing particles, 2.25 parts by weight of small-diameter diffusing particles, and 4 parts by weight of nanoscale inorganic metal oxide antistatic agent are uniformly mixed and stirred to obtain a diffusion coating....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com