Speed control device for backtrack of electrode original path in electric machining process

A speed control device, the technology of the original path, which is applied in the direction of program control, computer control, general control system, etc., can solve the problems of long return time, failure of return, and automatic speed change of the original path, so as to improve the efficiency of electric machining, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

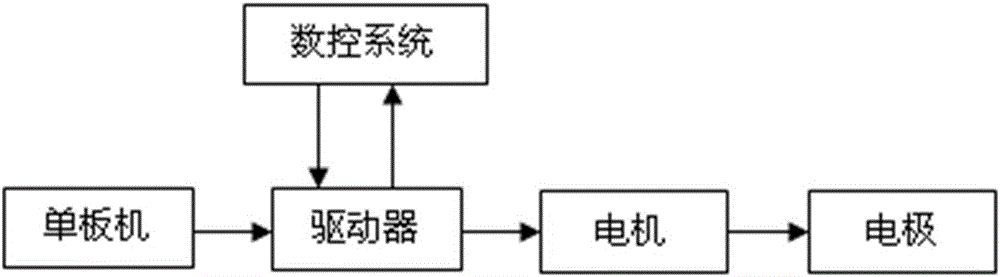

[0026] The single board computer in embodiment 1 is FPGA type, the driver is the NDrive driver produced by American AEROTECH, and the numerical control system is the open numerical control system A3200 based on industrial computer produced by American AEROTECH.

Embodiment 2

[0028] The single-board computer in Embodiment 2 is a DSP type, the driver is an NDrive driver produced by AEROTECH of the United States, and the numerical control system is an open numerical control system A3200 based on an industrial computer produced by AEROTECH of the United States.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com