Preparation of graphene-coated silver powder by hydrothermal method and preparation method of graphene-coated silver powder modified lead-free slurry

A technology of graphene coating and hydrothermal method, which is applied in the direction of photovoltaic power generation, metal/alloy conductors, electrical components, etc., can solve the problem of reducing the effective contact of silver particles, conductive paste containing metal lead and expensive, and increasing electrode series resistance and other problems, to achieve the effect of reducing recombination probability, improving photoelectric conversion efficiency, and enhancing open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

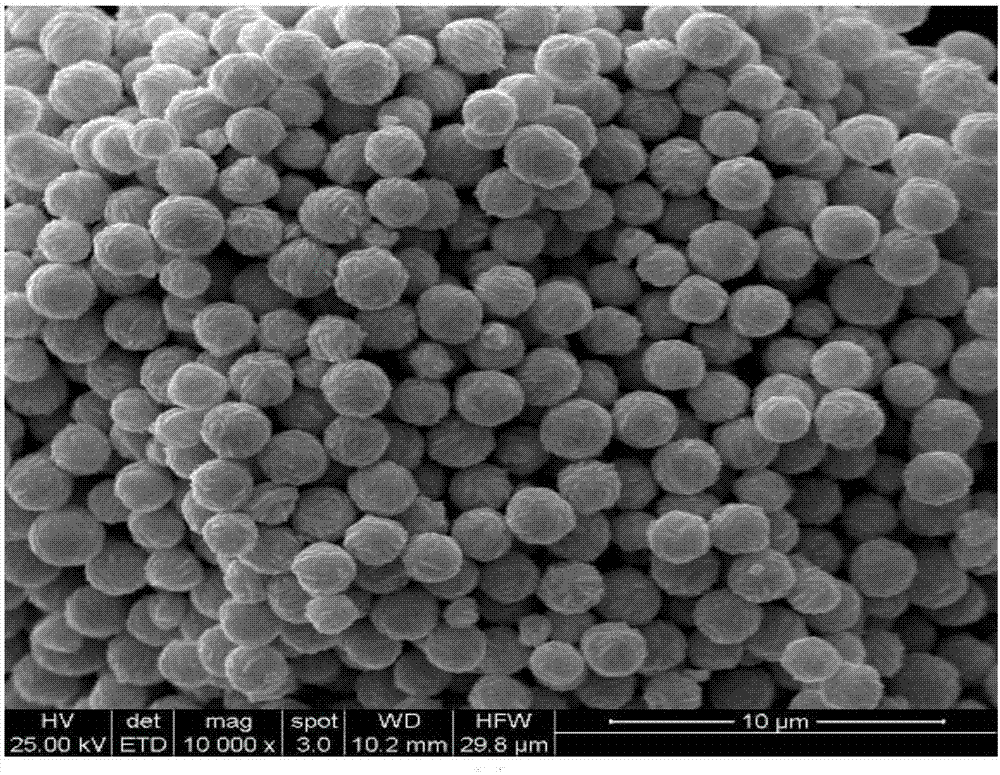

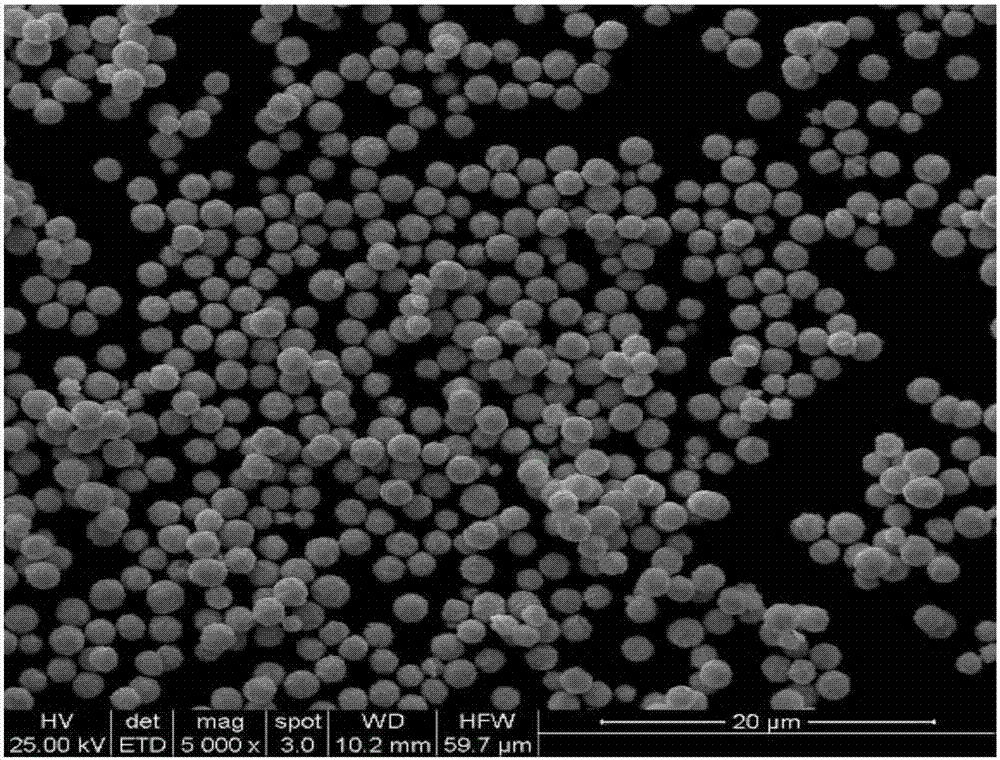

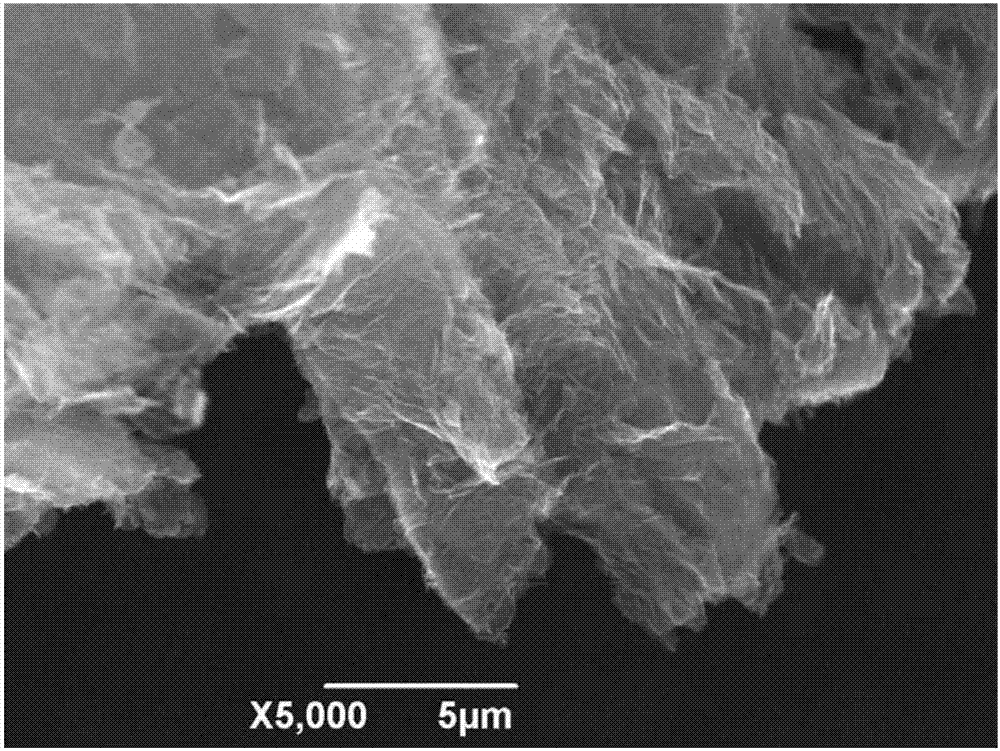

[0054] Specific embodiment one: present embodiment is to utilize hydrothermal method to prepare the method for graphene-coated silver powder, specifically completes according to the following steps:

[0055] 1. Preparation of silver powder:

[0056] ①. Mixing a silver nitrate solution with a concentration of 30g / L to 500g / L and a dispersant solution with a concentration of 10g / L to 100g / L to obtain a silver nitrate solution containing a dispersant;

[0057] The concentration described in step 1. is that the volume ratio of the dispersant solution of 10g / L~100g / L and the silver nitrate solution of 30g / L~500 / L is (0.3~3):1;

[0058] ②. Dissolving the reducing agent in distilled water to obtain a reducing agent solution;

[0059] The concentration of the reducing agent solution described in step 1.2 is 50g / L~150g / L;

[0060] ③. Mix the reducing agent solution with the silver nitrate solution containing the dispersant, then react at a stirring speed of 100r / min to 200r / min and a...

specific Embodiment approach 2

[0078] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the dispersant in the dispersant solution described in step one 1. is gelatin, polyvinylpyrrolidone, N-methylpyrrolidone, polyvinyl alcohol, triethanolamine , trisodium citrate and gum arabic, or a mixture of several of them. Others are the same as the first embodiment.

specific Embodiment approach 3

[0079] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the reducing agent described in step 1.2 is one of ascorbic acid, hydrazine hydrate and hydroquinone or a mixture of several of them. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com