Potassium element doped porous carbon nitride photocatalyst and its preparation method and application

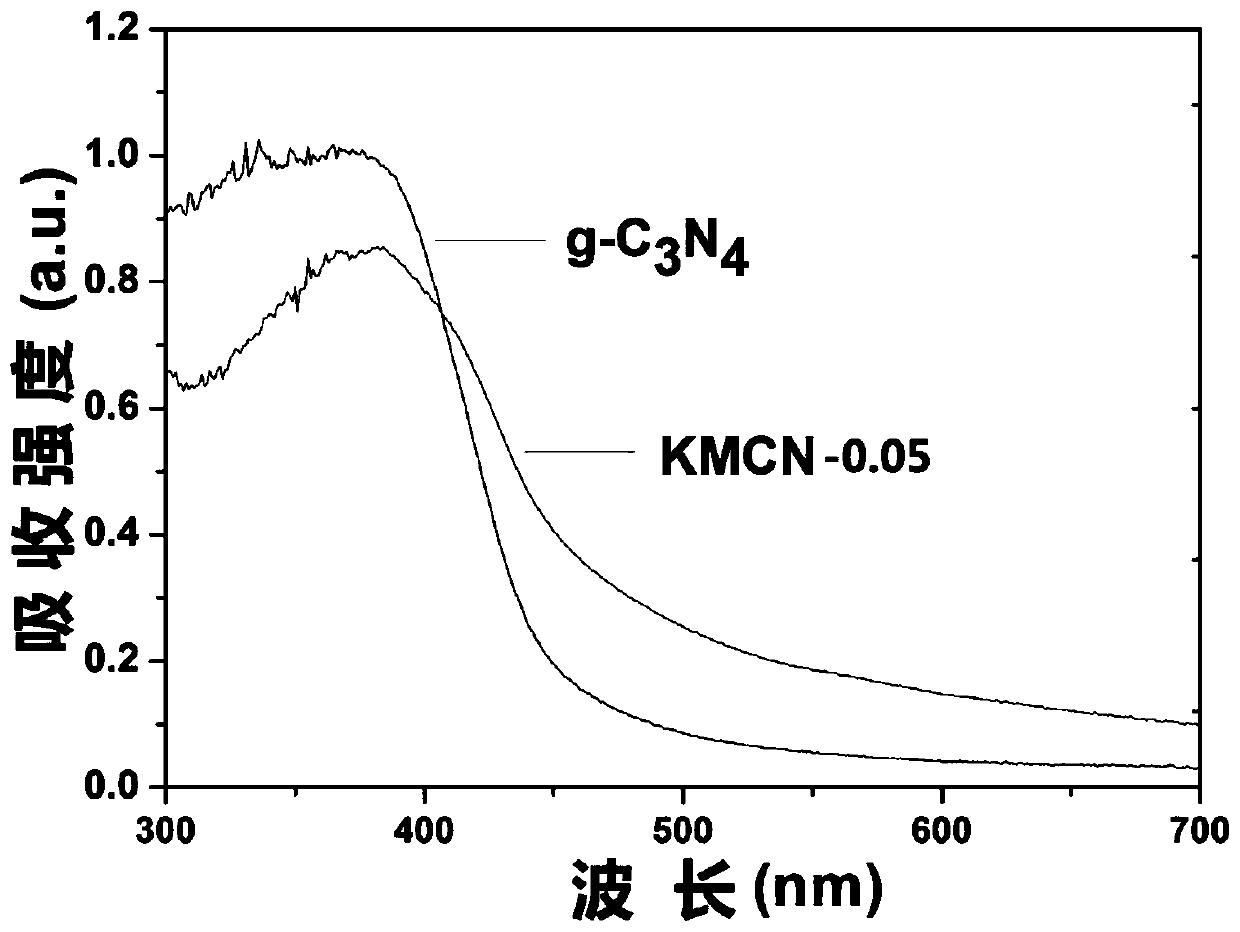

A technology of element doping and carbon nitride, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. Poor catalytic activity and other problems, to achieve the effects of strong visible light absorption ability, fast photogenerated carrier separation and migration ability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

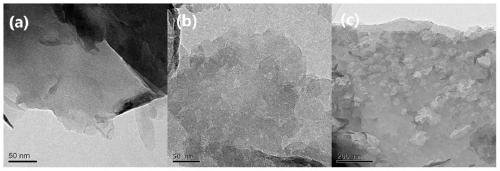

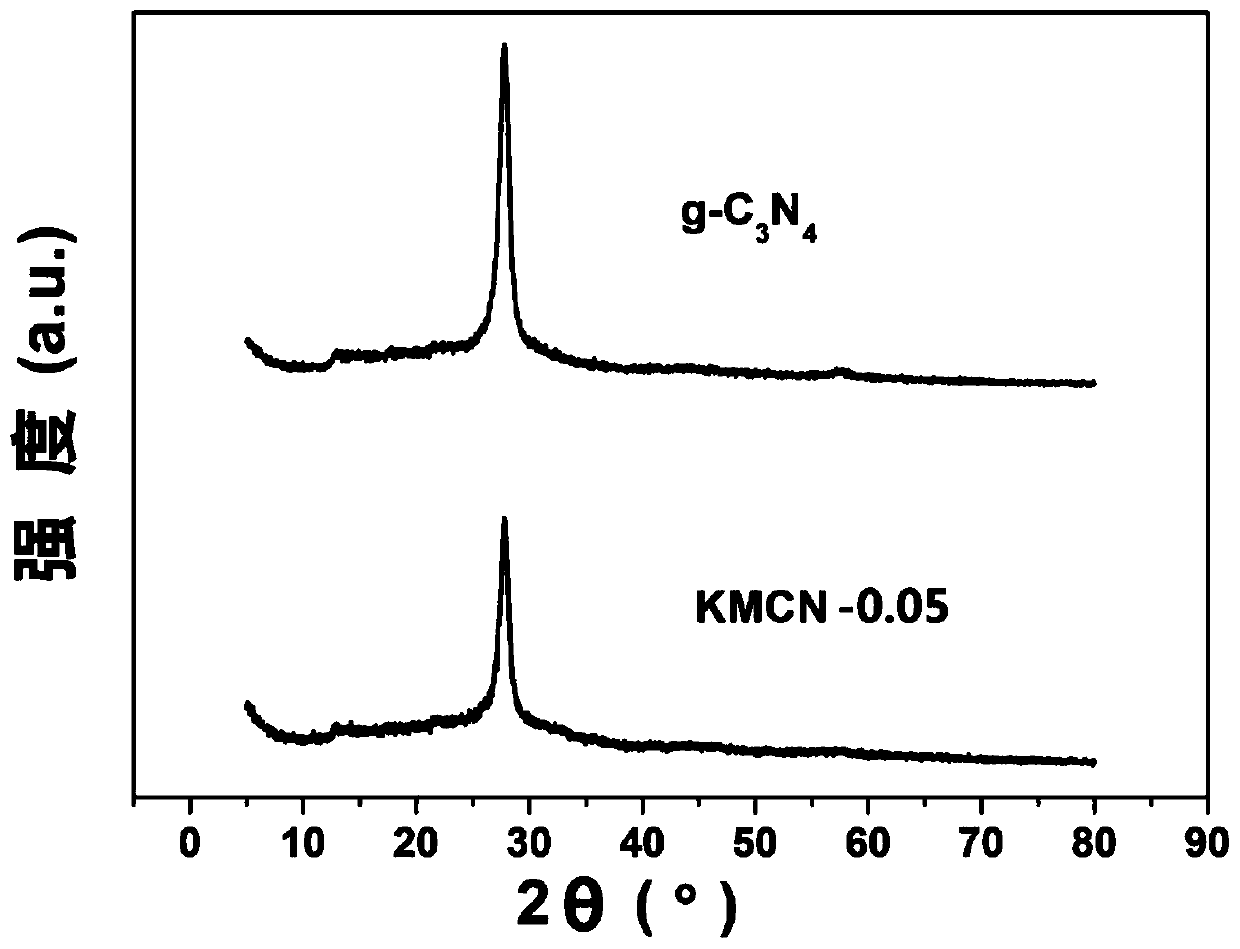

[0042] A potassium element doped porous carbon nitride photocatalyst comprises a porous carbon nitride material, wherein the porous carbon nitride material is doped with potassium element.

[0043] In this embodiment, the porous carbon nitride material has a sheet structure; the surface of the porous carbon nitride material has nanopores.

[0044] A kind of preparation method of potassium element doped porous carbon nitride photocatalyst in the above-mentioned present embodiment, comprises the following steps:

[0045] (1) Mix 0.3 g of porous carbon nitride material with 20 mL of potassium hydroxide solution with a concentration of 0.05 mol / L, and stir at a constant speed for 2 hours to mix the porous carbon nitride material and potassium hydroxide solution evenly, and the resulting mixture is stirred Dry under conditions to obtain a mixture.

[0046] (2) Put the mixture obtained in step (1) into a crucible, place it in a muffle furnace, raise the temperature to 550°C at a he...

Embodiment 2

[0058] A preparation method of potassium element-doped porous carbon nitride photocatalyst is basically the same as the preparation method in Example 1, except that the concentration of the potassium hydroxide solution used in the step (1) of Example 2 is 0. That is, the potassium hydroxide solution is replaced with water.

[0059] The potassium-doped porous carbon nitride photocatalyst prepared in Example 2 is marked as KMCN-0.

Embodiment 3

[0061] A preparation method of potassium element-doped porous carbon nitride photocatalyst is basically the same as the preparation method in Example 1, the difference is only that the concentration of potassium hydroxide solution used in the step (1) of Example 3 is 0.02mol / L.

[0062] The potassium-doped porous carbon nitride photocatalyst prepared in Example 3 is marked as KMCN-0.02.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com