Multifunctional demulsifier as well as preparation method and application method thereof

A demulsifier and multi-functional technology, which is applied in the field of non-metallic mineral functional material preparation and wastewater treatment, can solve the problems of single function, high price and high raw material cost, and achieve the effect of reducing cost, wide source and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides the preparation method of above-mentioned demulsifier, comprises the following steps:

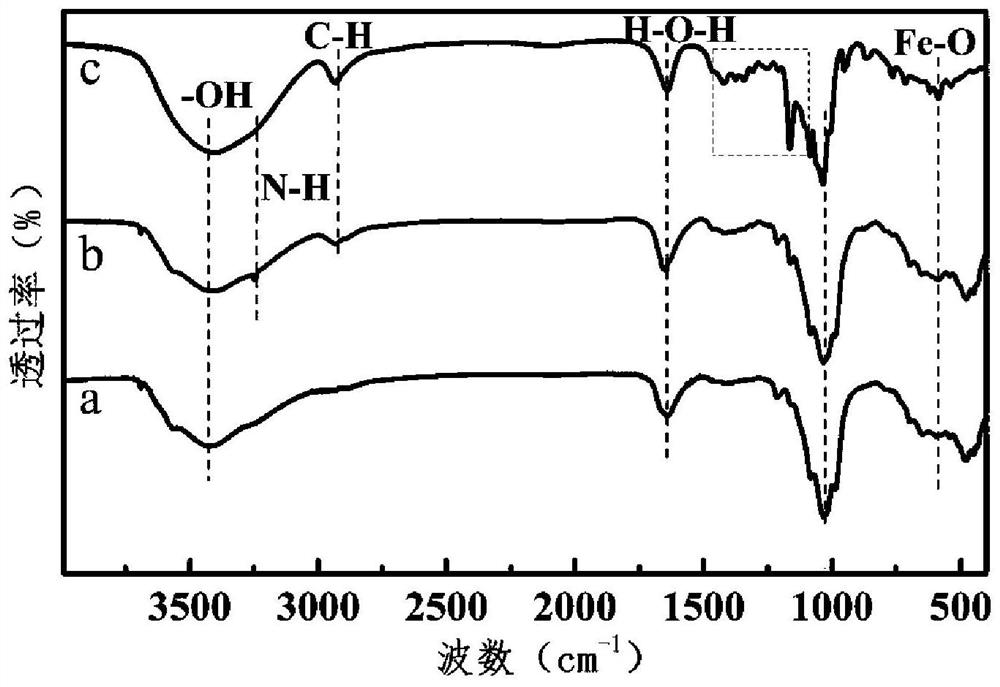

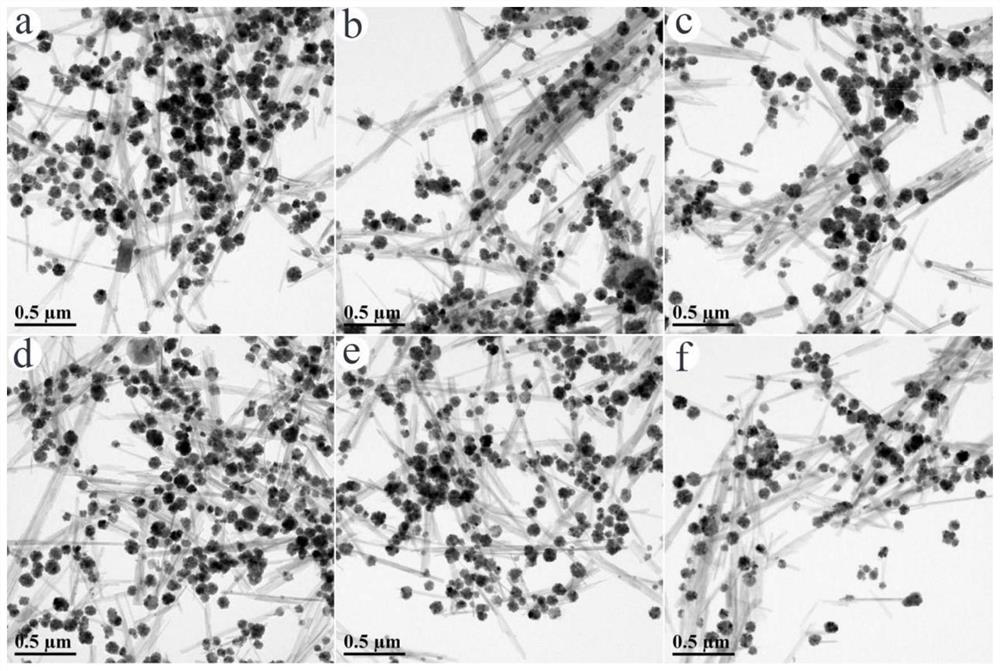

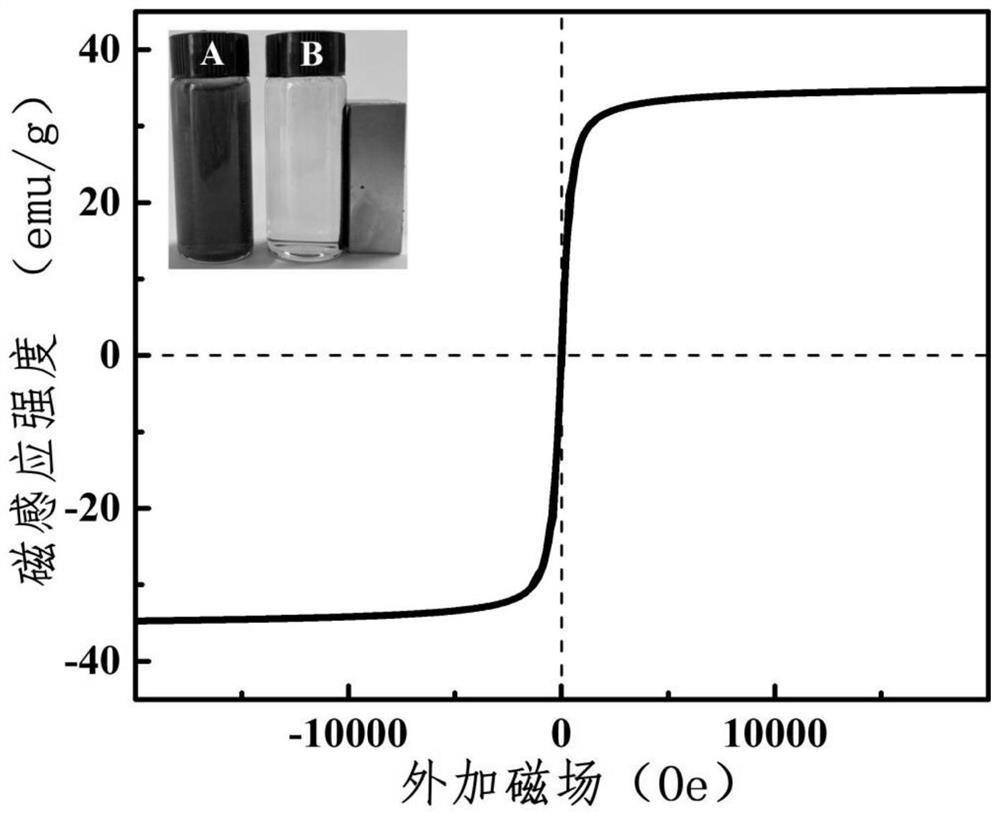

[0044] Step 1: Prepare the carrier, disperse the sepiolite powder into the solvent, add iron salt and zinc salt to obtain a mixed solution; place the mixed solution in a closed space for hydrothermal reaction, and the iron salt will generate trioxide in the hydrothermal reaction Iron and zinc salts generate zinc oxide in the hydrothermal reaction. After the reaction is completed, sepiolite, ferric oxide and zinc oxide compound to form a compound to obtain a carrier, wherein, in the carrier, sepiolite, ferric oxide and oxide The mass ratio of zinc is 10:5-27:0.6-1.8, and the particle size of the carrier measured by a laser particle size analyzer is 2 μm-18 μm.

[0045] In this step, the carrier of the compound of sepiolite, ferric oxide and zinc oxide is generated through hydrothermal reaction, and the particle size of the generated carrier is small...

Embodiment 1

[0065] 10kg of discarded sepiolite combined with chitosan after absorbing Congo red dye was crushed through a 200-mesh sieve, then dispersed in 190L of ethylene glycol, and 30kg of ferric chloride hexahydrate, 3kg of zinc chloride, 0.25 kg betaine and 2kg polyvinylpyrrolidone, ultrasonically stirred to completely dissolve and fully disperse evenly, then placed in a 300L hydrothermal reactor, and reacted at 198°C for 8 hours. After naturally cooling to room temperature, the product is centrifuged to obtain a carrier with a beaded structure loaded with carbon, zinc oxide nanoparticles and ferric oxide nanoparticles, and at the same time, ethylene glycol is recycled. After the obtained carrier was washed with water, it was dispersed into 100L of a mixed solution containing 1.8kg chitosan and 0.2kg chitosan oligosaccharide, so that the chitosan and chitosan oligosaccharide were fully coated on the surface of the carrier, and then dispersed into a solution containing 1kg β- Into th...

Embodiment 2

[0067] 10kg of discarded sepiolite combined with chitosan after absorbing tetracycline was crushed through a 200 mesh sieve, then dispersed in 190L of ethylene glycol, 10kg of iron sulfate, 3kg of zinc sulfate, 0.5kg of betaine and 0.5kg of Polyvinylpyrrolidone, ultrasonically stirred to make it completely dissolved and fully dispersed evenly, then placed in a 300L hydrothermal reactor, and reacted at 180°C for 15h. After naturally cooling to room temperature, the product is centrifuged to obtain a carrier with a beaded structure loaded with carbon, zinc oxide nanoparticles and ferric oxide nanoparticles, and at the same time, ethylene glycol is recycled. After the obtained carrier was washed with water, it was dispersed into 100L of a mixed solution containing 1.8kg chitosan and 0.2kg chitosan, so that the chitosan and chitosan were fully coated on the surface of the carrier, and then dispersed to a concentration of 0.5 kg after separation. Into the saturated solution of kgα-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com