A kind of cofe2o4/g-c3n4 magnetic nano material and preparation method thereof

A magnetic nanometer, g-c3n4 technology, applied in the field of materials, can solve problems such as environmental adverse effects, catalytic activity decline, and impact on recycling, so as to achieve the effect of increasing recycling rate, improving catalytic activity, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

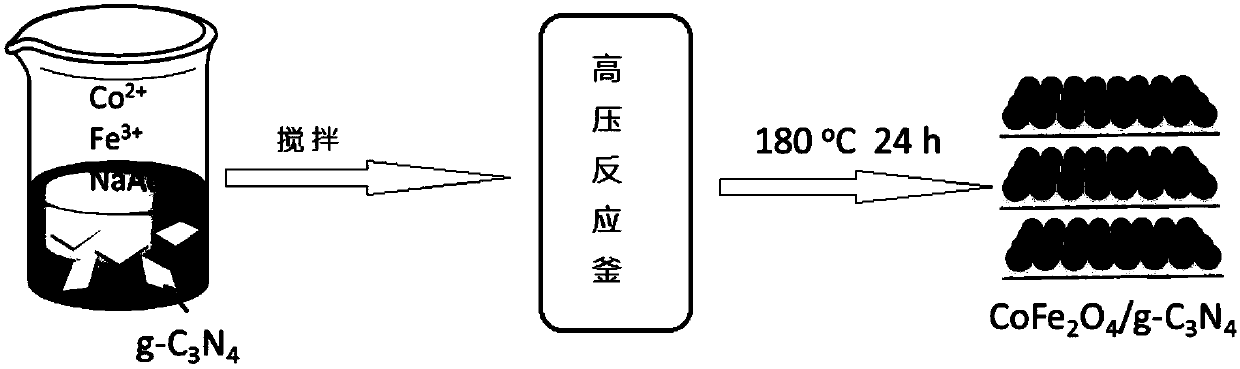

[0034] Example 1. CoFe 2 o 4 / g -C 3 N 4 Preparation method of magnetic nanomaterial

[0035] (1) g-C 3 N 4 Nanosheet Synthesis:

[0036] Put 5g of melamine into a crucible with a cover and place it in a muffle furnace, raise the temperature to 520°C at a rate of 5°C / min and keep it for 4h, and the obtained block g-C 3 N 4 Grind into powder, put it in the muffle furnace again and calcinate at 550°C for 3h to obtain g-C 3 N 4 Nanosheets.

[0037] (2)CoFe 2 o 4 / g -C 3 N 4 Synthesis of Magnetic Nanomaterials:

[0038] The g-C obtained in (1) 3 N 4 Weigh 200mg and disperse in 30mL ethylene glycol, ultrasonically disperse for 30min, after the belt is evenly dispersed, weigh 2mmol of FeCl 3 ·6H 2 O and 1 mmol of CoCl 2 4H 2 O was completely dissolved in the above solution, and 15 mmol of sodium acetate was weighed as a protective agent and added to the above solution, and the mixed solution formed by stirring at room temperature was poured into a 50 mL autoclave...

Embodiment 2

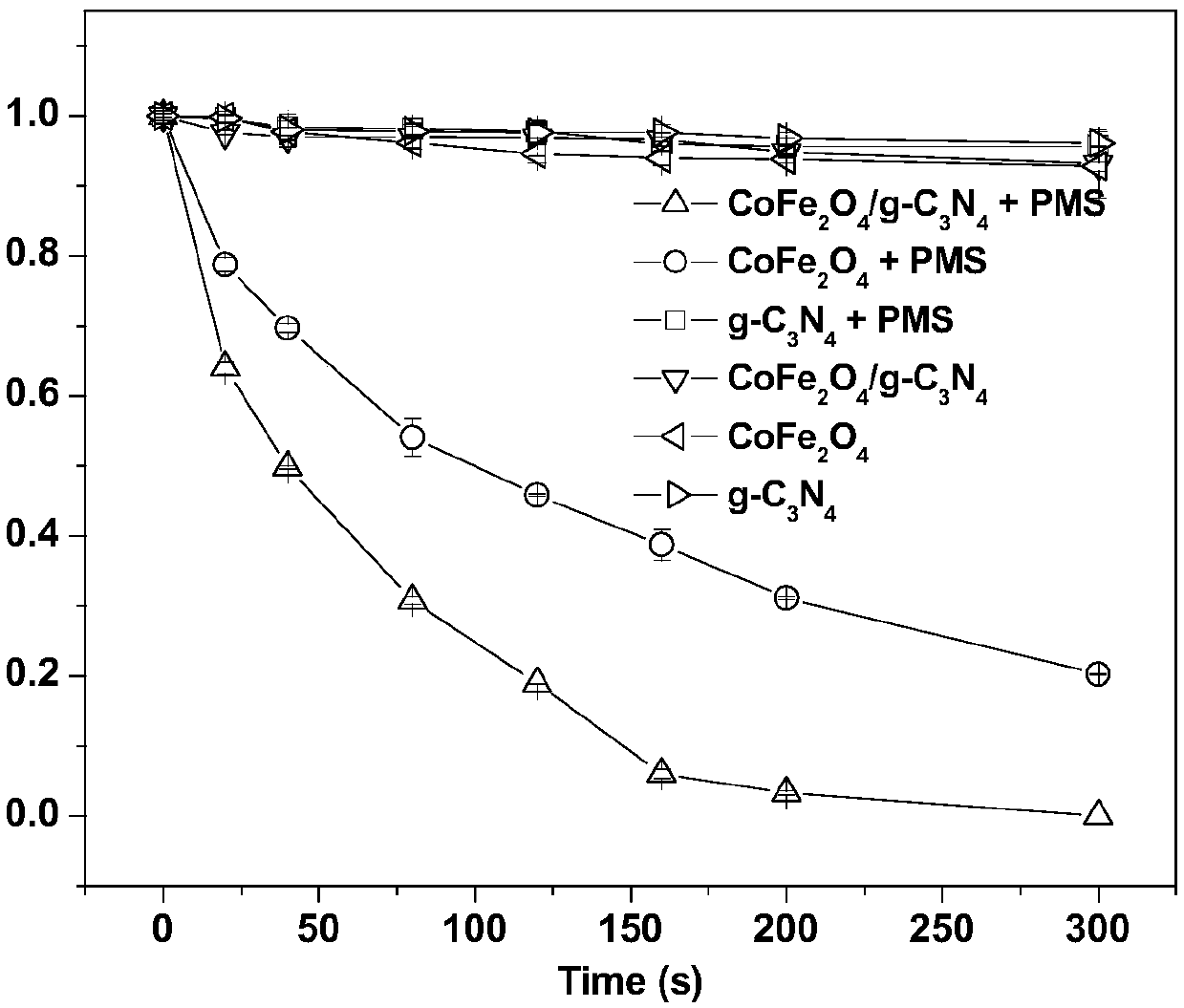

[0040] The catalytic degradation experiment was carried out at room temperature. Take six 250mL beakers and add 100mL deionized water to each, add 1mL sulfonamide solution with a concentration of 1g / L, and then weigh the following six combinations and add them to the six beakers respectively. (1) 10mg CoFe 2 o 4 / g -C 3 N 4 +10mg PMS; (2) 10mg CoFe 2 o 4 +10mg PMS; (3) 10mg g-C 3 N 4 +10mg PMS; (4) 10mg CoFe 2 o 4 / g -C 3 N 4 ; (5) 10mg CoFe 2 o 4 ; (6) 10mg g-C 3 N 4 . Start timing from the addition of PMS, take 1mL samples at regular intervals, add 1mL methanol to quench SO4·- to stop sulfonamide degradation, and use HPLC to measure the remaining sulfonamide concentration. Experimental results ( figure 2 ) shows: CoFe 2 o 4 / g -C 3 N 4 The nanocomposite catalyzed PMS to produce SO4·-oxidative degradation of sulfonamide was very efficient, and the sulfonamide was completely degraded within 5min, while in the single CoFe 2 o 4 Under the catalysis of nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com