Preparation method for lithium-iron phosphate cathode material, and lithium ion battery

A technology for lithium iron phosphate and cathode materials, applied in the direction of positive electrodes, secondary batteries, battery electrodes, etc., can solve the problems of low compaction density, high cost, complex and cumbersome preparation process, etc., and achieve high compaction density and low cost , The effect of streamlining the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

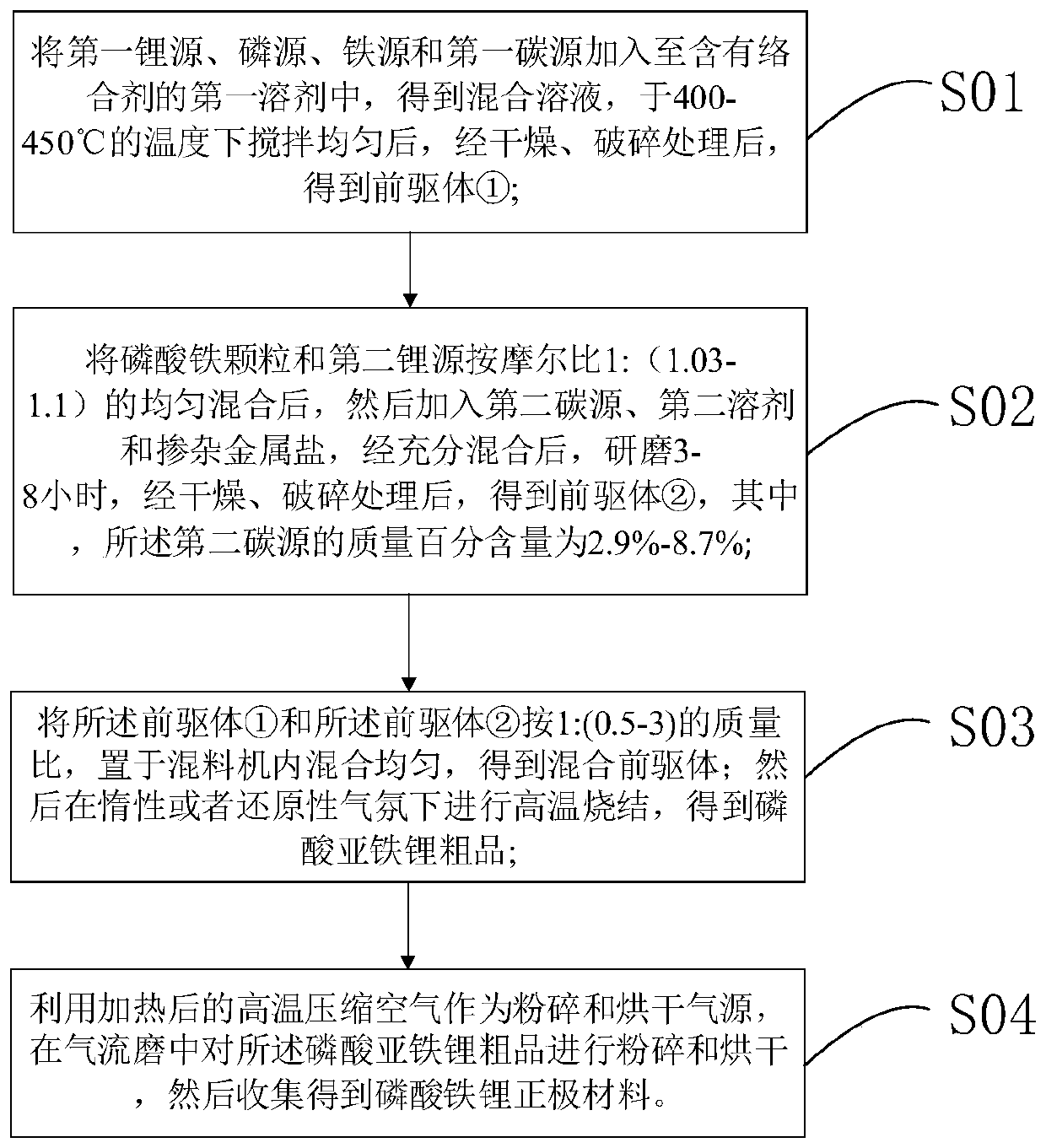

[0055] Such as figure 1 As stated, in one embodiment of the present invention, a method for preparing a lithium iron phosphate cathode material is provided, comprising the following steps:

[0056] S01. Add the first lithium source, phosphorus source, iron source and first carbon source to the first solvent containing complexing agent to obtain a mixed solution, stir evenly at a temperature of 400-450°C, dry and crush After processing, the precursor ① is obtained;

[0057] S02. After uniformly mixing the iron phosphate particles and the second lithium source in a molar ratio of 1:(1.03-1.1), then add the second carbon source, the second solvent and the doping metal salt, and after fully mixing, grind for 3- 8 hours, after drying and crushing, the precursor ② was obtained, wherein the mass percentage of the second carbon source was 2.9%-8.7%;

[0058] S03. Put the precursor ① and the precursor ② in a mass ratio of 1:(0.5-3), place them in a mixer and mix them evenly to obtain...

Embodiment 1

[0062] A preparation method of lithium iron phosphate cathode material, comprising the following steps:

[0063] (1) Add lithium carbonate, ammonium dihydrogen phosphate, and ferrous oxalate into the reaction kettle at a molar ratio of 0.5:1:1, then add an appropriate amount of glucose and an appropriate amount of methanol, adjust the pH to 7.0, heat at a temperature of 420°C and Stir for 125 minutes until uniform, react to form a complex, dry at 120°C with a dryer, and then crush with a crusher until the particle size of the powder is within the range of 0.1<D90<0.6μm to obtain the precursor ①;

[0064] (2) Select ferric phosphate particles and lithium carbonate to mix and stir evenly at a molar ratio of 1:1.036, then add 6.9% glucose, 4.3% methanol and 0.26% MgSO 4 , after fully mixing, grinding for 7.5 hours, drying at 120°C with a dryer, and crushing with a crusher until the particle size is within the range of 1.1μm<D90<2.5μm to obtain the precursor②;

[0065] (3) Mix th...

Embodiment 2

[0069] A preparation method of lithium iron phosphate cathode material, comprising the following steps:

[0070] (1) Add lithium hydroxide, phosphoric acid and ferrous sulfate in a molar ratio of 3:1:1 to the reaction kettle, then add an appropriate amount of carbon nanotubes and ethanol, adjust the pH to 7.0, and heat at a temperature of 420°C , while stirring for 125 minutes until uniform, reacting to form a complex, drying at 120°C with a dryer, and then crushing with a crusher until the particle size of the powder is within the range of 0.4<D90<0.6μm to obtain the precursor ①;

[0071] (2) Select ferric phosphate particles and lithium hydroxide to mix and stir evenly in a ratio of 1:1.036, then add 6.9% glucose, 4.3% methanol and 0.26% Ti(NO 3 ) 4 , after fully mixing, grinding for 7.5 hours, drying at 120°C with a dryer, and crushing with a crusher until the particle size is within the range of 1.5μm<D90<2.5μm to obtain the precursor②;

[0072] (3) The precursor ① and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com