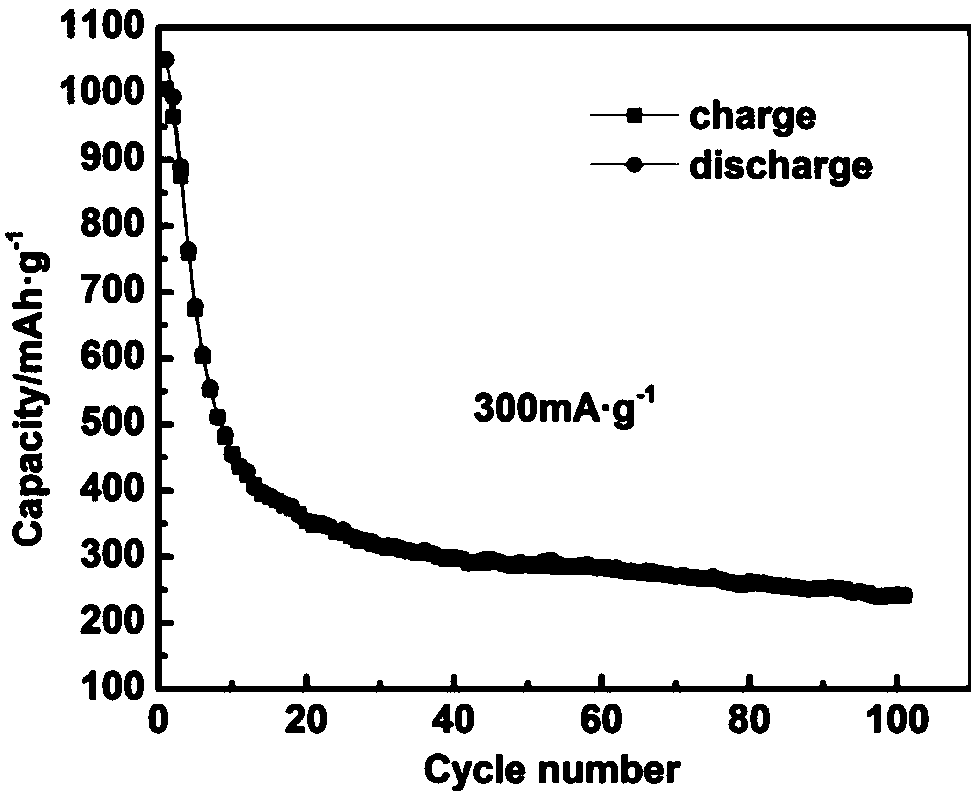

A kind of preparation method of sns2/tio2 sodium ion battery anode material with high cycle performance

A sodium-ion battery, cycle performance technology, applied to battery electrodes, circuits, electrical components, etc., can solve the problems of small yield of nanosheets, incomplete reaction, poor controllability, etc., to achieve excellent cycle performance, good cycle stability, strong crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A high cycle performance SnS 2 / TiO 2 A preparation method for a negative electrode material for a sodium ion battery, comprising the following steps:

[0027] 1) SnCl 4 ·5H 2 Dissolve O in deionized water and prepare a solution A with a concentration of 0.6-1.0 mol / L, according to the mass ratio of elements m Sn :m S =(1.85~2.8):(1.0~1.53) sodium thiosulfate is dissolved in an equal amount of deionized water (that is, with dissolved SnCl 4 ·5H 2 The amount of deionized water of O is equal to) to be prepared into solution B;

[0028] 2) Under the action of magnetic stirring, add solution B dropwise into solution A, and continue stirring to obtain a uniform mixed solution C;

[0029]3) According to the element molar ratio n Ti :n Sn =(1~5): The ratio of 10 is to dissolve butyl titanate in absolute ethanol to obtain mixed solution D, and the ratio of absolute ethanol to the total volume of deionized water used in step 1) is (1~5): (1~7), under the action of magn...

Embodiment 1

[0034] 1) SnCl 4 ·5H 2 O was dissolved in deionized water and prepared into a solution A with a concentration of 0.6mol / L, according to the element mass ratio m Sn :m S =1.85:1.0 Sodium thiosulfate is dissolved in an equal amount of deionized water to prepare solution B;

[0035] 2) Add solution B dropwise into solution A under the action of magnetic stirring, and keep stirring to obtain a uniformly mixed solution C.

[0036] 3) According to the element molar ratio n Ti :n Sn = 1:10 ratio Dissolve butyl titanate in absolute ethanol to obtain a mixed solution D, the total volume ratio of absolute ethanol to deionized water is 1:1, add the mixed solution D dropwise under the action of magnetic stirring To mixed solution C to obtain solution E. Add 5mol / L dilute HNO dropwise to the mixed solution E 3 , adjust solution pH=3 to form solution F;

[0037] 4) Put the F solution into a homogeneous hydrothermal reactor and seal it, and control the filling ratio at 40%, put it in...

Embodiment 2

[0040] 1) SnCl 4 ·5H 2 O was dissolved in deionized water and prepared into a solution A with a concentration of 0.8mol / L, according to the element mass ratio m Sn :m S =2.0:1.3 Sodium thiosulfate is dissolved in an equal amount of deionized water to prepare solution B;

[0041] 2) Add solution B dropwise into solution A under the action of magnetic stirring, and keep stirring to obtain a uniformly mixed solution C.

[0042] 3) According to the element molar ratio n Ti :n Sn = 3:10 ratio Dissolve butyl titanate in absolute ethanol to obtain a mixed solution D, the total volume ratio of absolute ethanol to deionized water is 2:3, add the mixed solution D dropwise under the action of magnetic stirring To mixed solution C to obtain solution E. Add 5mol / L dilute HNO dropwise to the mixed solution E 3 , adjust solution pH=7 to form solution F;

[0043] 4) Put the F solution into a homogeneous hydrothermal reactor and seal it, and control the filling ratio at 50%, put it int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com