Microminiature activating device for thermal batteries

An activation device and thermal battery technology, which is applied in the fields of fuzes, missiles and aerospace thermal batteries, can solve the problems of large volume, short activation time, and small occupied space, and achieve high storability, short activation time, and small occupied space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

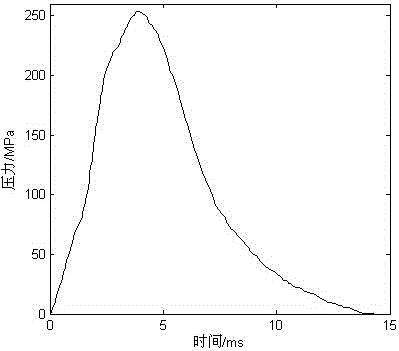

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific experimental examples to facilitate a clear understanding of the present invention, but they do not limit the present invention.

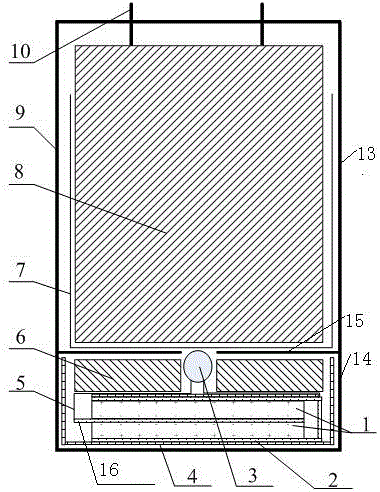

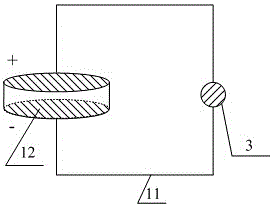

[0032] combine figure 1 Shown: a miniature thermal battery activation device, including piezoelectric ceramic sheet 1, electrode 2, electric ignition head 3, insulating layer 4, insulated wire 5, gravity block 6, ignition strip 7, single battery 8, shell Body 9, battery electrode 10, piezoelectric ceramic stack 12;

[0033] The housing 9 is configured as a cylinder, and the housing 9 is configured as an upper layer 13 and a lower layer 14,

[0034] The upper layer 13 is provided with a single battery 8 inside, the top of the single battery 8 is provided with a battery electrode 10 upward, and the outer wall and bottom end of the single battery 8 are provided with an ignition strip 7,

[0035] The lower layer 14 is sequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com