Inner-magnet moving-coil speaker multi-channel magnetic circuit system

A magnetic circuit system and multi-channel technology, applied in the field of loudspeakers, can solve the problems of disturbing the normal movement of the diaphragm, burning out the voice coil, and uneven heat dissipation of the system as a whole, so as to optimize the electro-acoustic performance and application performance, and increase the heat dissipation scale. , The effect of uniform heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

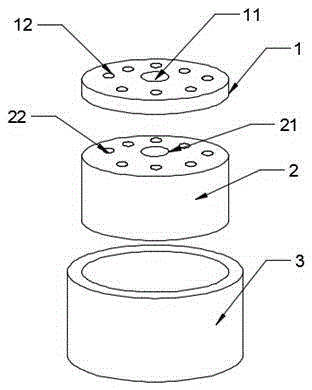

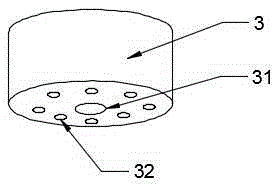

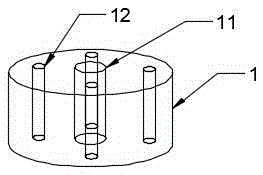

[0021] see Figure 1-3 , a multi-channel magnetic circuit system for an internal magnetic moving coil speaker, comprising a multi-channel magnetic plate 1, a multi-channel magnet 2 and a multi-channel magnetic bowl 3, the multi-channel magnetic plate 1 is made of low-carbon steel or the like A circular cake shape made of magnetic material that passes through multiple channels. The multi-channel magnet 2 is a cylindrical shape with multiple channels made of NdFeB material. The multi-channel magnetic conduction bowl 3 is made of low carbon steel, etc. The shape of a round cup made of a magnetically conductive material that passes through multiple channels; the multi-channel magnet 2 is arranged in the multi-channel magnetic conduction bowl 3, the multi-channel magnetic plate 1 is arranged on the multi-channel magnet 2, and the multi-channel magnet The magnetic plate 1, the multi-channel magnet 2 and the multi-channel magnetic bowl 3 are all provided with a plurality of through h...

Embodiment 2

[0025] see figure 1 , 2 , 4, a multi-channel magnetic circuit system of an internal magnetic moving coil speaker, the difference from Embodiment 1 is that the central axis of the multi-channel magnetic plate 1 is provided with a central through hole 11 of the magnetic plate, and the magnetic plate There are six magnetic plate side holes 12 evenly distributed around the central hole 11; the central axis of the multi-channel magnet 2 is provided with a magnet center through hole 21, and six magnet side holes 22 are evenly distributed around the magnet center through hole 21; A central through hole 31 is arranged in the center of the bottom of the multi-channel magnetic conductive bowl 3 , and six side holes 32 are distributed around the central through hole 31 of the magnetic conductive bowl.

Embodiment 3

[0027] see figure 1 , 2 , 5, a multi-channel magnetic circuit system of an internal magnetic moving coil speaker, the difference from Embodiment 1 is that the central axis of the multi-channel magnetic plate 1 is provided with a central through hole 11 of the magnetic plate, and the magnetic plate There are eight magnetic plate side holes 12 evenly distributed around the center hole 11; the central axis of the multi-channel magnet 2 is provided with a magnet center through hole 21, and eight magnet side holes 22 are evenly distributed around the magnet center through hole 21; The central through-hole 31 of the center of the bottom of the multi-channel magnetic bowl 3 is axially provided with a central through hole 31 of the magnetic bowl, and eight side holes 32 of the magnetic bowl are distributed around the central through hole 31 of the magnetic bowl.

[0028] The present invention improves the performance of the current magnetic circuit that only has one hole in the axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com