Piezoelectric element-driven valve and flow-rate control device including piezoelectric element-driven valve

A technology of flow control device and piezoelectric element, applied in non-electric variable control, piezoelectric device/electrostrictive device, flow control and other directions, can solve the damage of piezoelectric element, trouble in assembly, increase piezoelectric actuator Stroke and other issues, to achieve the effect of increasing displacement and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

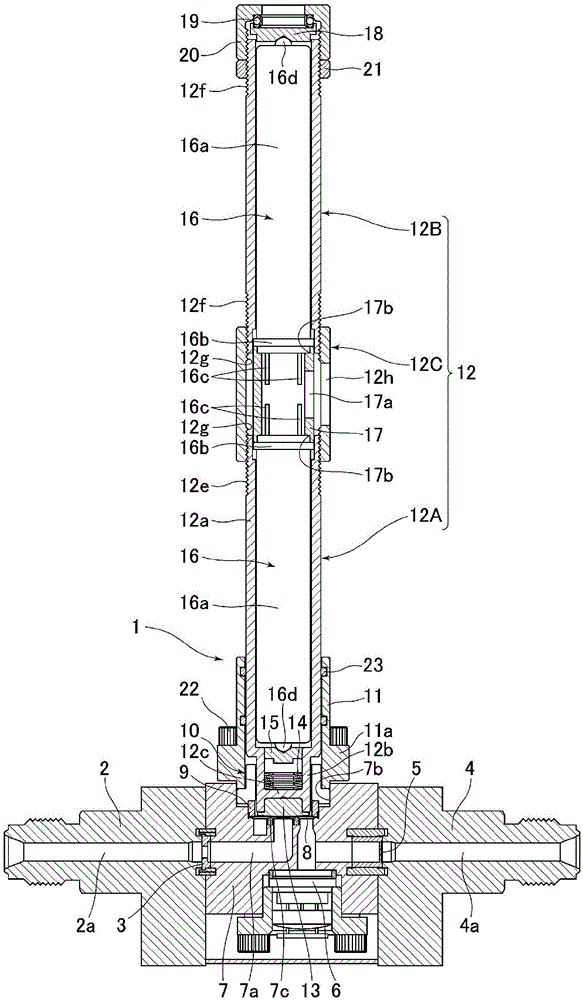

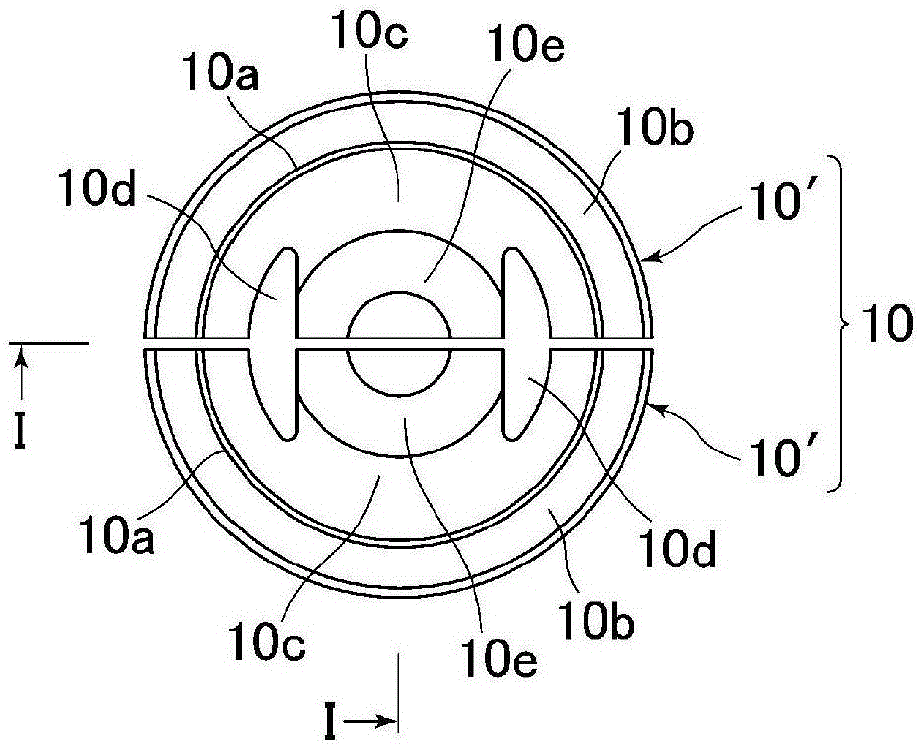

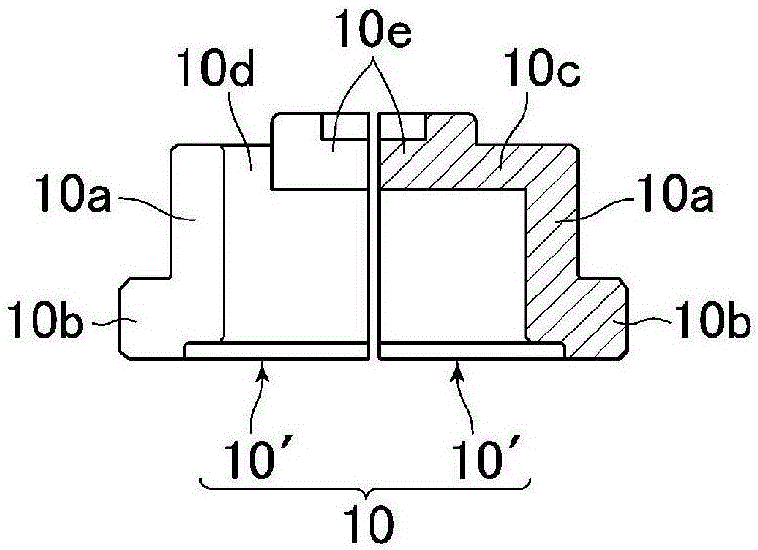

[0110] figure 1 A flow rate control device including a piezoelectric element-driven valve 1 according to an embodiment of the present invention is shown. The flow rate control device includes: a piezoelectric element-driven valve 1; As shown in the figure) is screwed and fixed on the upstream side of the main body 7 of the piezoelectric element-driven valve 1, and an inlet-side fluid passage 2a communicating with the fluid passage 7a of the main body 7 is formed; the gasket 3 for sealing is interposed (inserted) Provided between) the main body 7 and the inlet side block 2; the outlet side block 4, which is screwed and fixed on the downstream side of the main body 7 of the piezoelectric element-driven valve 1 by bolts (not shown), and is formed with the main body The outlet-side fluid passage 4a communicated with the fluid passage 7a of 7; the washer-type orifice 5 (o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com