Personalized pedicle screw drilling template with quick-change drill sleeve and its preparation method

A pedicle and screw placement technology, applied in the field of medical devices, can solve the problems of easy wear and melting of catheters, expensive navigation equipment, lack of effective theory and means for pedicle screw placement channel planning, etc., to ensure accuracy. and safety, excellent biomechanical properties, firm three-dimensional fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

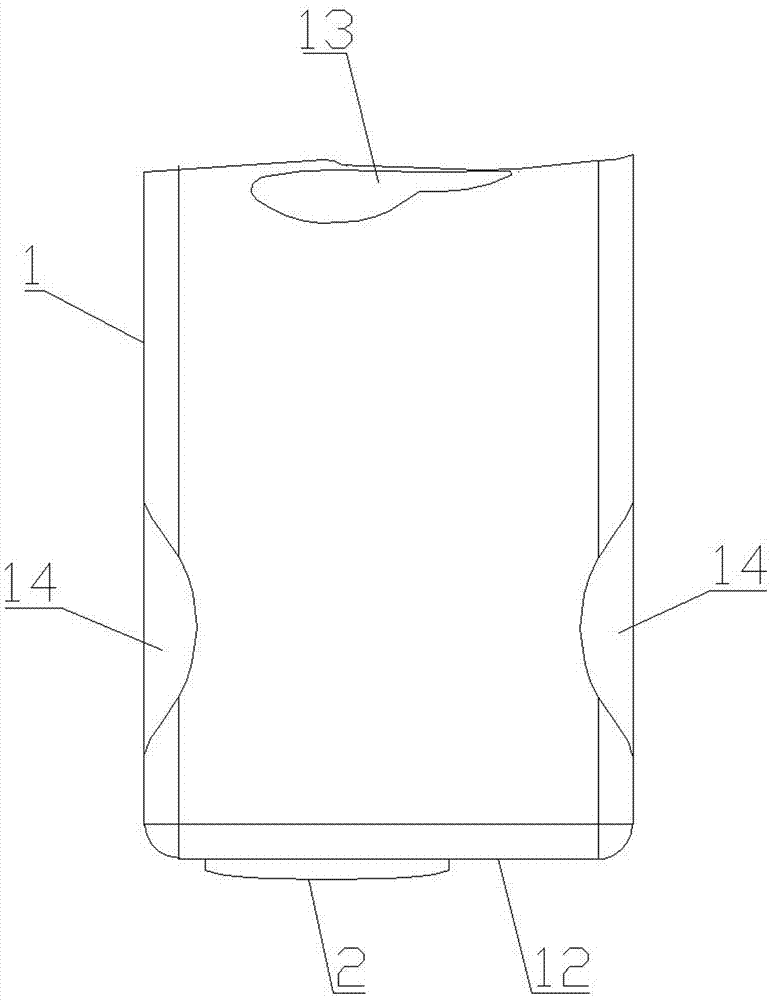

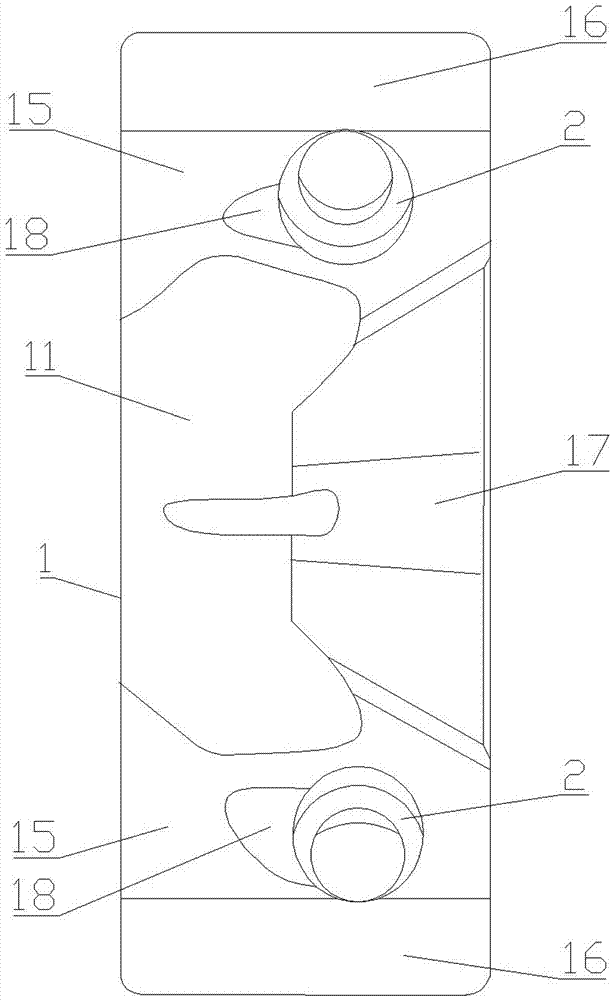

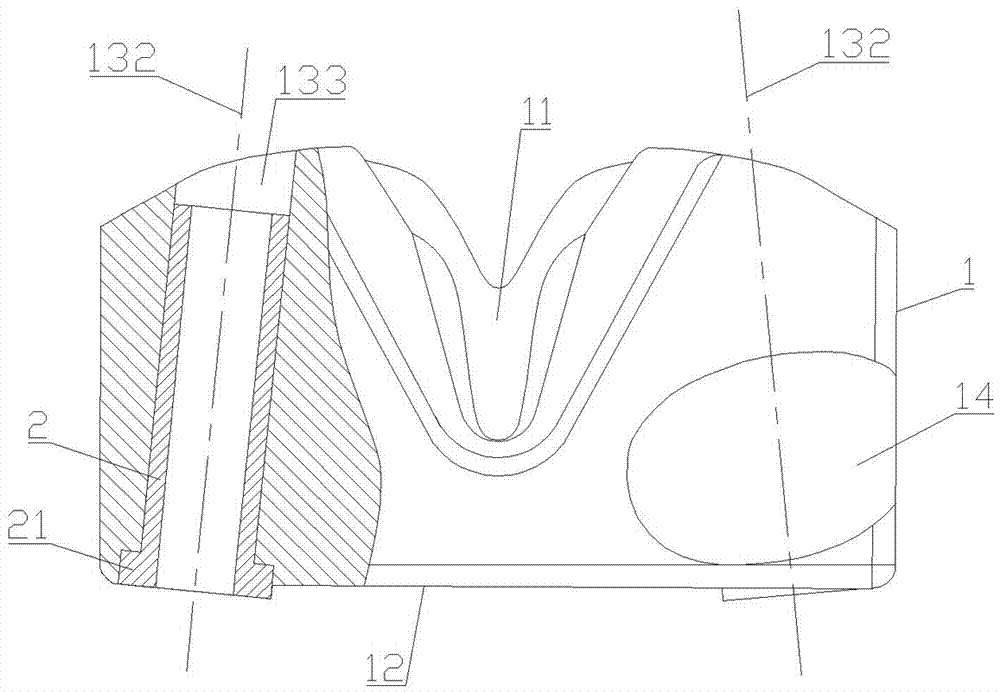

[0049] Such as Figure 1~6 As shown, the personalized pedicle screw drilling template with quick-change drill sleeves includes the main body 1 and the drill sleeve 2.

[0050] The lower end of the body 1 is provided with a bone fitting surface 11 and a bottom surface 15 , and the upper end is provided with a nail placement plane 12 . The main body is provided with two nail placement channels 13 , one end of the nail placement channel 13 runs through to the nail placement plane 12 , and the other end runs through to the bottom surface 15 . The bone-fitting surface 11 adheres to and coincides with the contours of the lamina of the target vertebra 31 , the posterior portion of the transverse process, and the dorsal side of the root of the spinous process. When the bone-fitting surface 11 is attached and coincident with the target vertebra 31 , the central axis 132 of the nail placement channel 13 coincides with the central axis of the largest inscribed elliptical cylinder of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com