Non-uniform electrostatic field efficient impurity removing equipment

An electrostatic field and non-uniform technology, which is applied in the field of high-efficiency impurity removal equipment for non-uniform electrostatic fields, can solve the problems of inability to remove neutral impurities in oil, unfavorable equipment use safety, and poor purification effect, etc., to achieve simple structure and easy to use The effect of long life and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

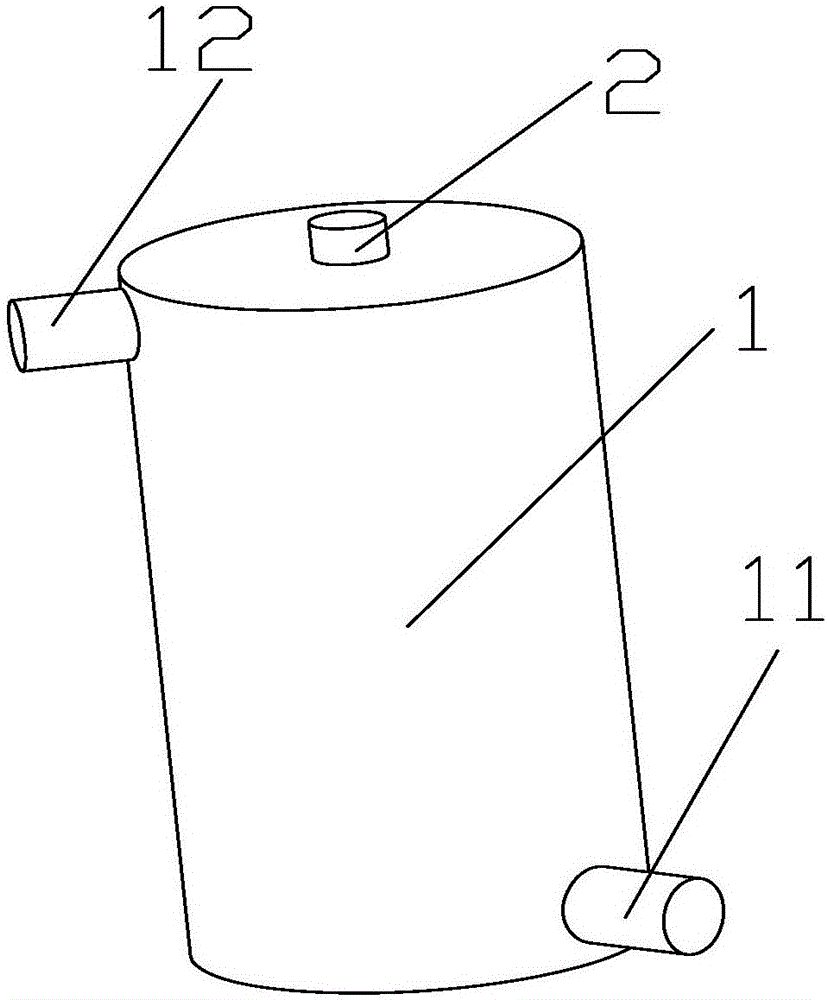

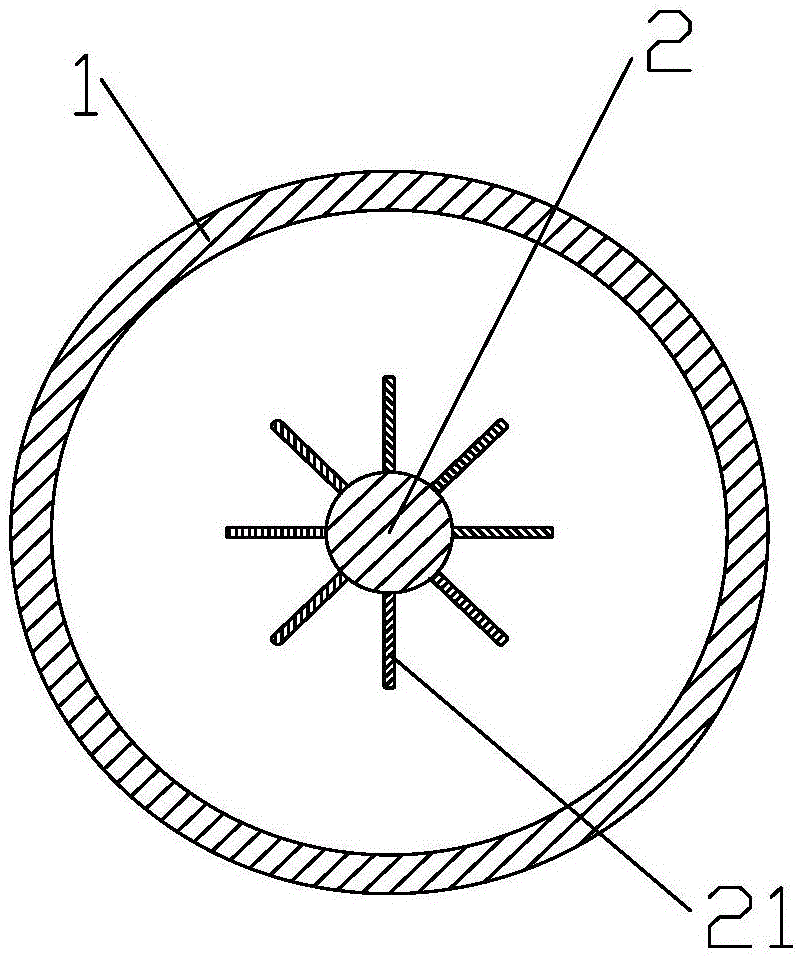

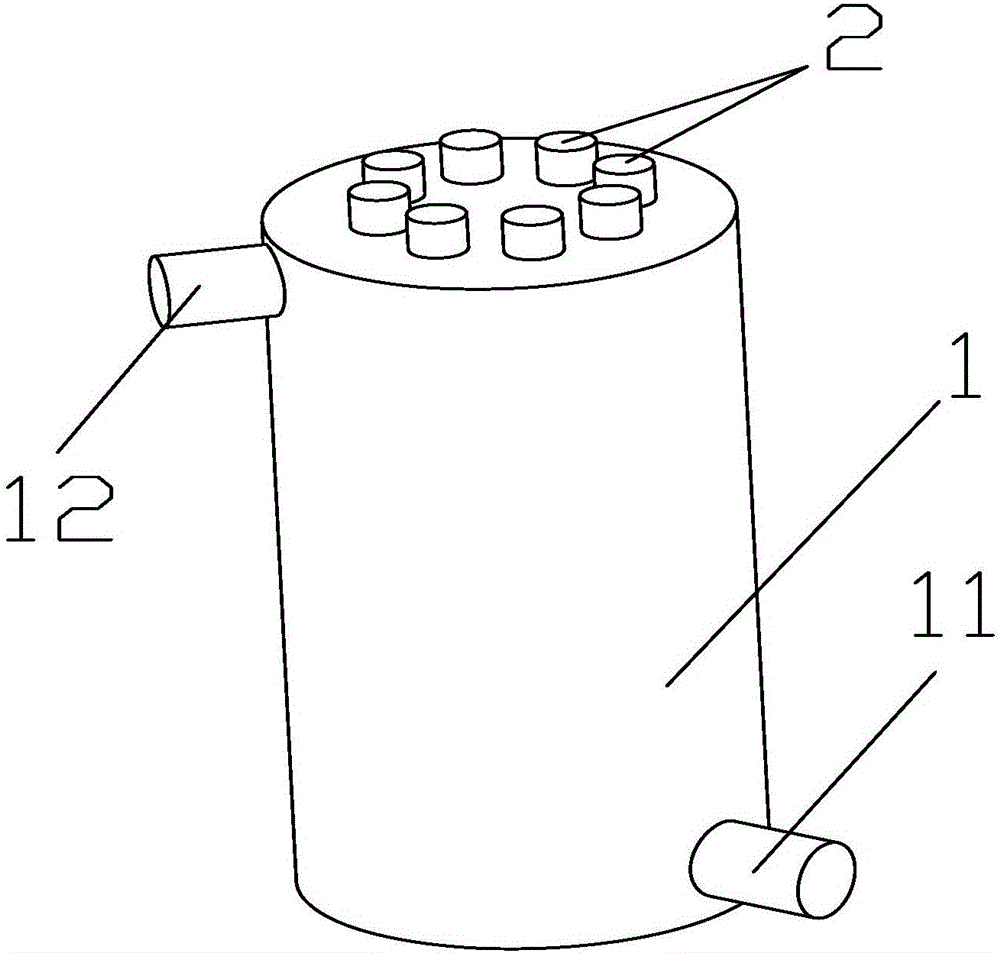

[0029] refer to figure 1 and figure 2 The first embodiment of the non-uniform electrostatic field high-efficiency impurity removal device shown includes a closed cylindrical shell 1. In this embodiment, the shell 1 is made of conductive material, and it can also be directly placed on a non-conductive material in actual use. The insulating material is directly evaporated on the top, the lower part of the casing 1 is provided with an inlet 11 communicating with the interior of the casing, and the upper part is provided with an outlet 12 communicating with the interior. The inlet 11 and the outlet 12 are preferably located on different semicircle outer walls of the casing 1 , preferably the projected distance between the two on the horizontal plane is equal to the diameter of the shell 1, so that the flow stroke of the fluid flowing in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com