Anti-H2S-CO2-corrosion pipeline submerged arc welding wire

A technology of submerged arc welding wire and submerged arc welding, which is applied in the direction of arc welding equipment, welding/cutting medium/material, welding medium, etc., and can solve problems such as lack of CO corrosion resistance, corrosion failure of pipelines and equipment, and economic losses. Achieve excellent H2S and CO2 corrosion resistance, excellent H2S and CO2 corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A suitable for anti-H 2 S and CO 2 Corrosion pipeline submerged arc welding wire, its main chemical composition (weight percent): C 0.01, Si 0.05, Mn 0.3, P 0.004, S 0.002, Cr 3.6, Mo 1.2, Cu 0.3, the balance is iron and unavoidable impurities .

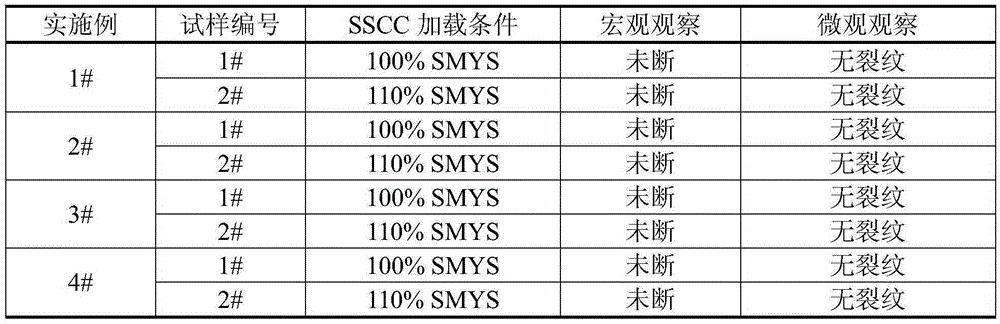

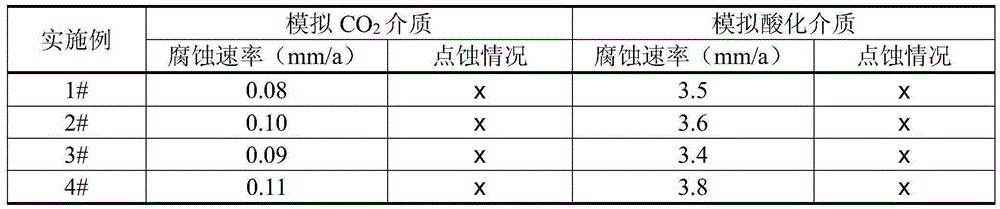

[0028] The specification of the welding wire is 4.0mm in diameter, which is matched with welding RF60E and used for submerged arc butt joint test of 26mm thick steel plate X80. Four wire submerged arc welding is adopted, the welding heat input is 48kJ / cm, and the four wire currents are 600, 800, 800 and 1000A respectively. No defects were found in post-weld ultrasonic, magnetic particle inspection, and X-ray inspections. The mechanical properties of the welded joints are listed in Table 1.

Embodiment 2

[0030] A suitable for anti-H 2 S and CO 2 Corrosion pipeline submerged arc welding wire, its main chemical composition (weight percent): C 0.015, Si 0.08, Mn 0.4, P 0.0045, S 0.0015, Cr 3.3, Mo 0.9, Cu 0.25, the balance is iron and unavoidable impurities .

[0031] The specification of the welding wire is 4.0mm in diameter, which is matched with welding RF60E and used for submerged arc butt joint test of 20mm thick steel plate X80. Single-wire multi-layer multi-pass welding is adopted, the welding heat input is 50kJ / cm, and the current is 750A. No defects were found in post-weld ultrasonic, magnetic particle inspection, and X-ray inspections. The mechanical properties of the welded joints are listed in Table 1.

Embodiment 3

[0033] A suitable for anti-H 2 S and CO 2 Submerged arc welding wire for corroding pipelines, its main chemical composition (weight percentage): C 0.01, Si 0.04, Mn 0.2, P 0.003, S 0.001, Cr 2.1, Mo 1.0, Cu 0.30, the balance is iron and unavoidable impurities .

[0034] The welding wire specification is 3.2mm in diameter, which is matched with welding RF60E and used for submerged arc butt joint test of 26mm thick steel plate X70. Double-sided, double-wire welding is adopted, the welding heat input is 60kJ / cm, and the current is 500 and 650A respectively. No defects were found in post-weld ultrasonic, magnetic particle inspection, and X-ray inspections. The mechanical properties of the welded joints are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com