High temperature roasting furnace of hydrogenation catalyst

A technology of high-temperature roasting furnace and hydrogenation catalyst, which is applied in the field of roasting furnaces. It can solve problems such as falling off of flight boards and baffle plates, lack of radiation protection boards, and damage to materials, so as to prevent falling off, reduce broken rate, and reduce temperature difference stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

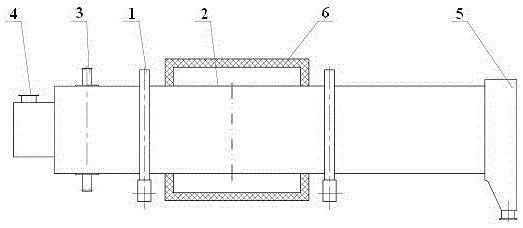

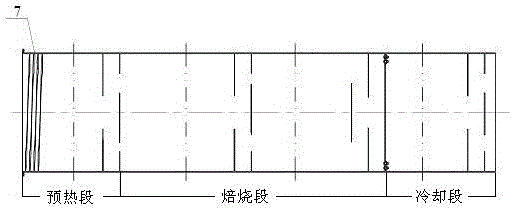

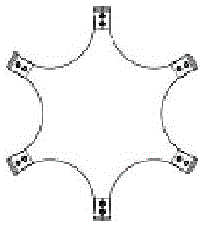

[0019] like figure 1 , 2 As shown in , 3, the hydrogenation catalyst high-temperature roasting furnace includes a cylinder body 2 supported by a support system 1 and divided into a preheating section, a roasting section and a cooling section in sequence, and a transmission system 3 connected to the cylinder body 2, the cylinder body One end of 2 is connected to the feeding system 4, and the other end is connected to the discharging system 5; a heating system 6 is provided outside the preheating section; a fin-type lifting board, a split-type baffle plate and a The spiral baffle plate 7 at the 4 ends of the feeding system; a radiation shield is provided between the roasting section and the cooling section.

[0020] The cylinder body 2 is a single cylinder structure.

[0021] When in use, the material is fed by the feeding system 4, and then enters the high-temperature roasting furnace. The high-temperature roasting furnace cylinder 2 is driven by the transmission system 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com