Two-dimensional black phosphorus nanosheet and liquid-phase peeling preparation method thereof

A liquid phase exfoliation and nanosheet technology, applied in the preparation of phosphorus, nanotechnology, nanotechnology and other directions, can solve the problems of difficult removal of organic solvents, small size, high yield of liquid phase exfoliation, and achieve high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

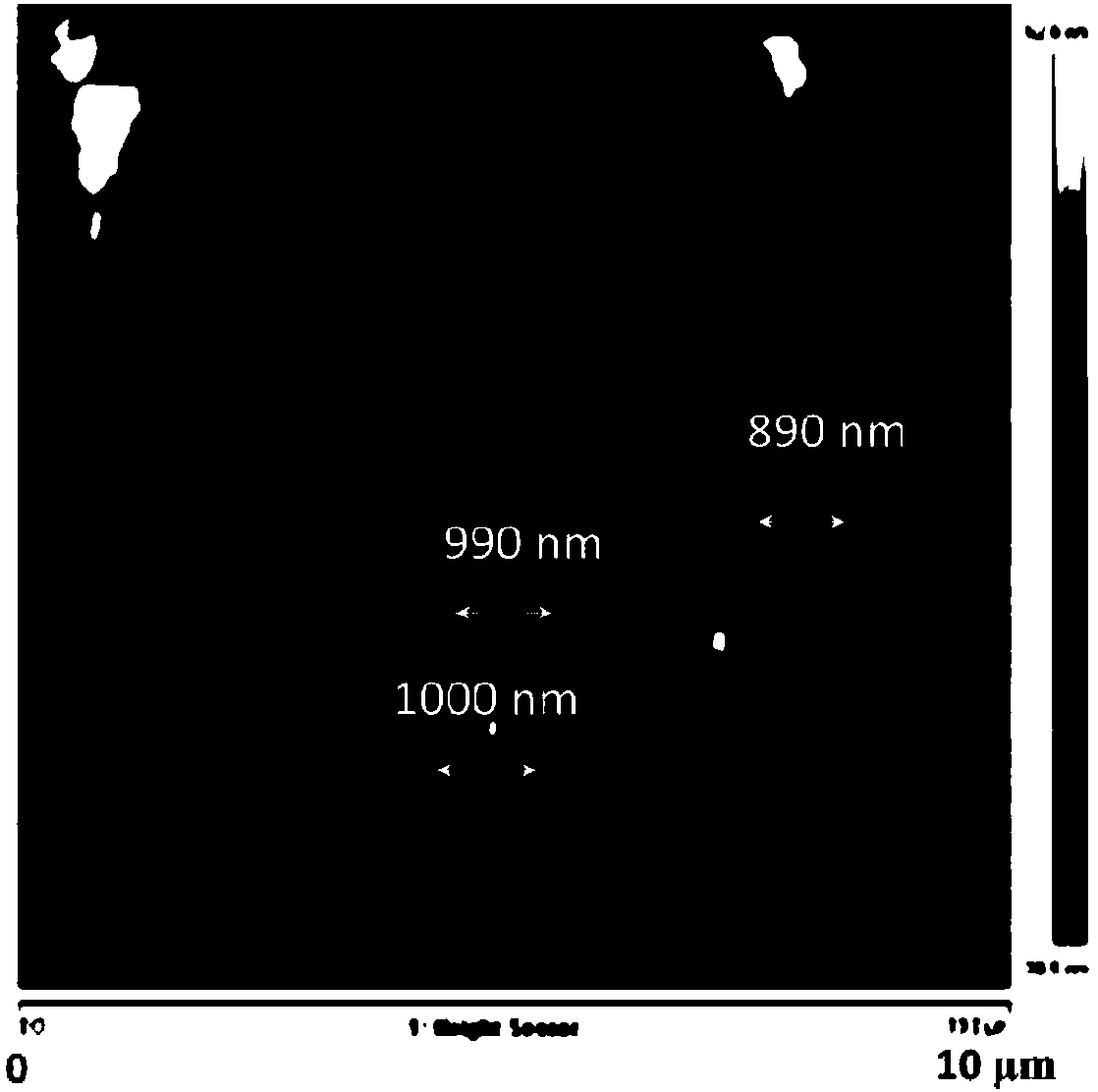

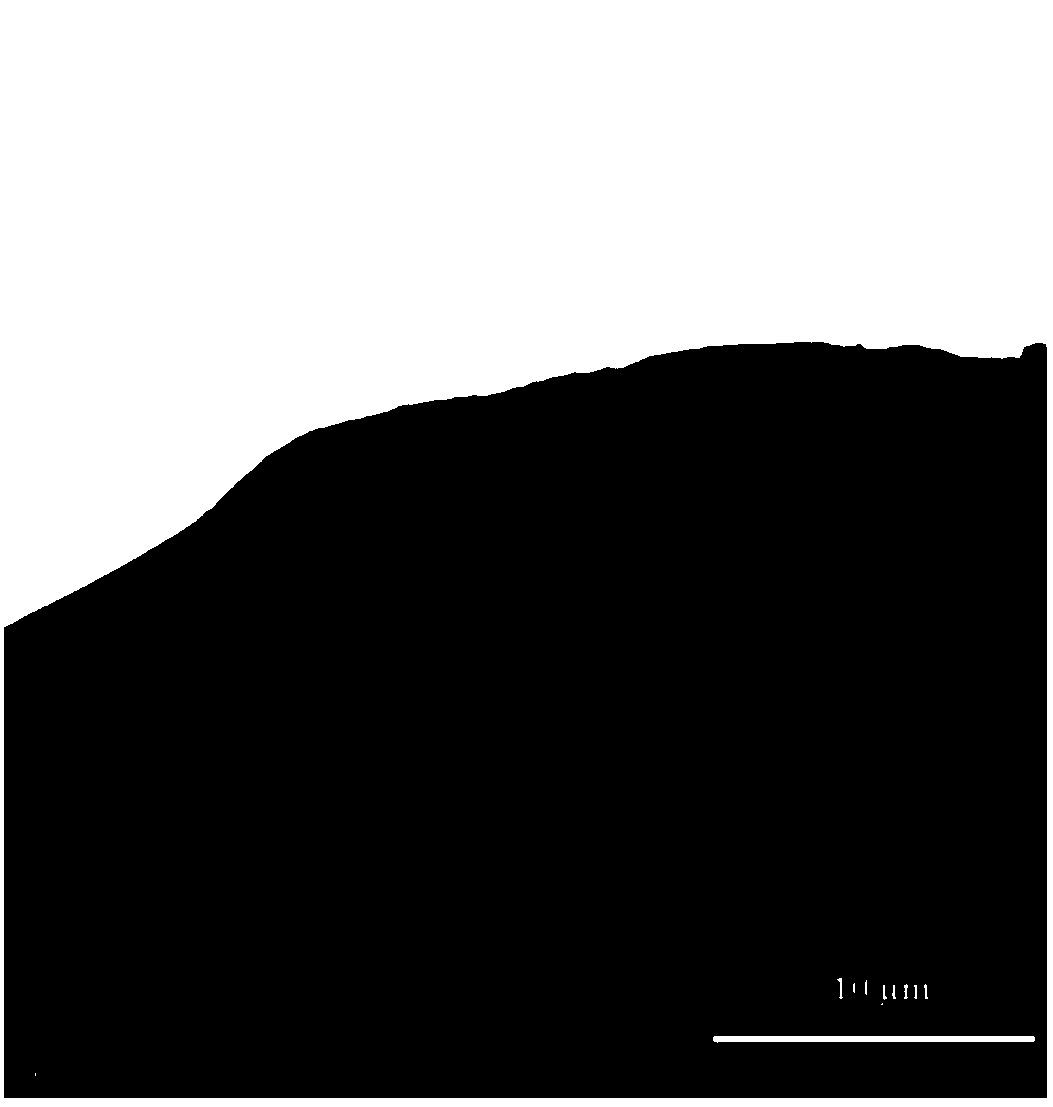

[0036] A preparation method for liquid phase exfoliation of two-dimensional black phosphorus nanosheets, comprising the following steps:

[0037] Step (1): drying tri-n-butyl(methyl)phosphine hexafluorophosphate in vacuum at 100°C for 48 hours;

[0038] Step (2): Add 10 mg of block black phosphorus and 5 mg of dried tri-n-butyl(methyl)phosphine hexafluorophosphate into 40 mL of N-methylpyrrolidone in a weight ratio of 1:0.5 , to obtain a mixed solution, wherein the concentration of black phosphorus in N-methylpyrrolidone is 0.25mg / mL, and the probe is ultrasonicated for 3h with a power of 900W under the sealed condition, and the temperature is controlled at 5°C during the entire probe ultrasonic process. °C; and then ultrasonicated in a water bath at a power of 500W for 3h, and the temperature was kept at 5 °C during the entire process of ultrasonication in a water bath. Then, it was left to stand overnight, and the supernatant was taken for centrifugation at 7000 rpm to obta...

Embodiment 2

[0040] A preparation method for liquid phase exfoliation of two-dimensional black phosphorus nanosheets, comprising the following steps:

[0041] Step (1): drying tri-n-butyl(methyl)phosphine hexafluorophosphate in vacuum at 100°C for 48 hours;

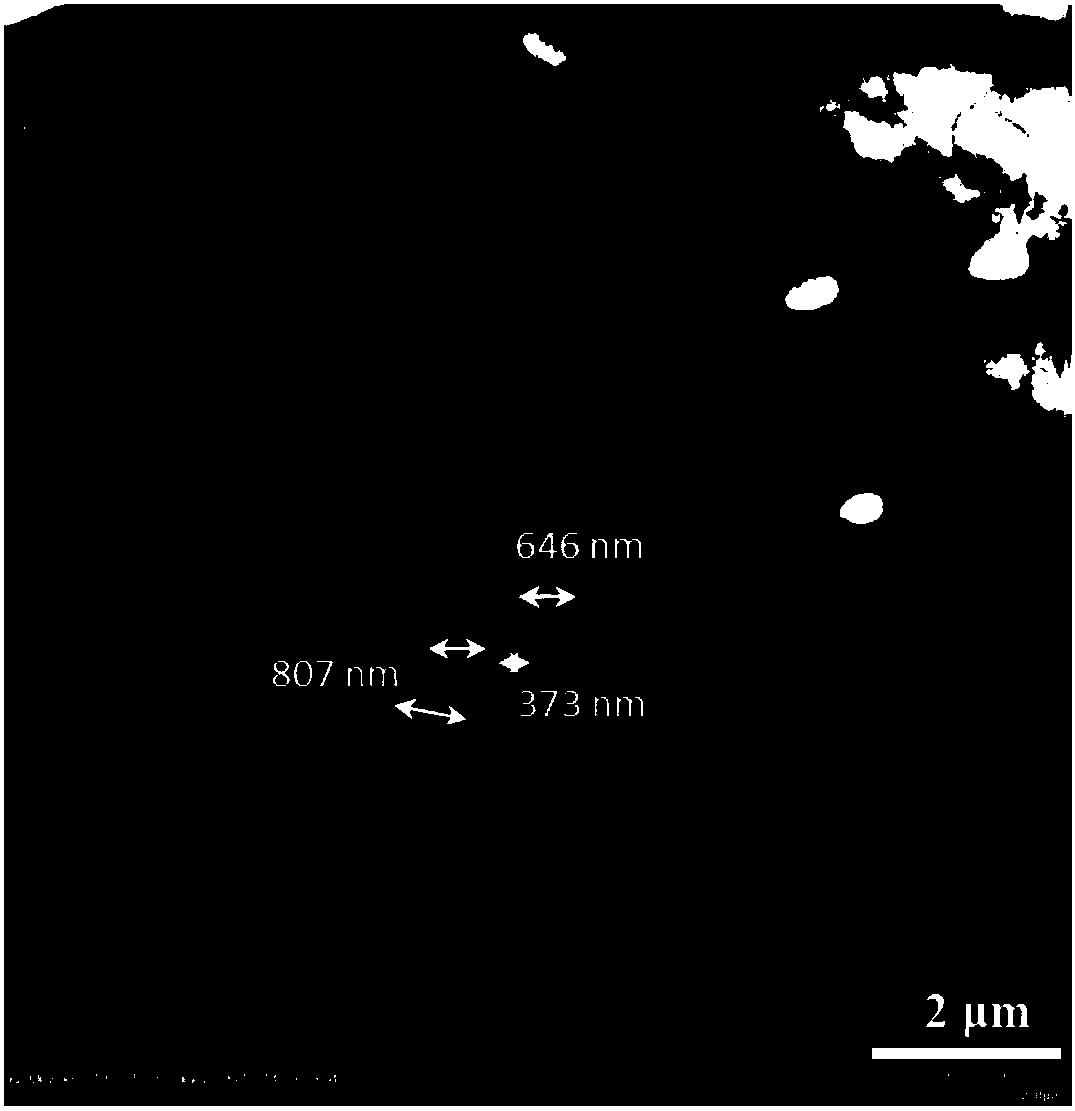

[0042] Step (2): Add 10 mg of block black phosphorus and 50 mg of dried tri-n-butyl(methyl)phosphine hexafluorophosphate into 2 mL of N-methylpyrrolidone in a weight ratio of 1:5 (NMP) to obtain the mixed solution, wherein the concentration of black phosphorus in N-methylpyrrolidone is 5mg / mL, and the probe ultrasonic 3h is carried out with the power of 900W under the sealed condition, and the temperature is controlled during the whole probe ultrasonic process to keep at 5°C; then perform ultrasonication in a water bath with a power of 500W for 3h, and keep the temperature at 5°C during the entire process of ultrasonication in a water bath. Then, it was left to stand overnight, and the supernatant was taken for centrifugation at 7000...

Embodiment 3

[0044] A preparation method for liquid phase exfoliation of two-dimensional black phosphorus nanosheets, comprising the following steps:

[0045] Step (1): drying tri-n-butyl(methyl)phosphine hexafluorophosphate in vacuum at 100°C for 48 hours;

[0046] Step (2): Add 10mg of block black phosphorus and 75mg of dried tri-n-butyl(methyl)phosphine hexafluorophosphate to 0.2mL of N-methylpyrrolidone in a weight ratio of 1:7.5 (NMP) to obtain a mixed solution, wherein the concentration of black phosphorus in N-methylpyrrolidone is 50mg / mL, and the probe is ultrasonicated for 3h with a power of 900W under a sealed condition, and the temperature is controlled during the entire probe ultrasonic process Keep it at 5°C; then conduct ultrasonication in a water bath with a power of 500W for 3h, and keep the temperature at 5°C during the whole process of ultrasonication in a water bath. Then, it was left to stand overnight, and the supernatant was taken for centrifugation at 7000 rpm to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com